| Availability: | |

|---|---|

| Quantity: | |

The 4WREE series proportional valve is a direct-acting proportional directional valve, with its core function being the proportional adjustment of oil flow direction and volume through integrated control electrical components (OBE). This series of valves is driven by proportional solenoids and can accept voltage or current signals to achieve precise continuous control.

Core functionality

The core function of the 4WREE series proportional valve is **proportional control**, which precisely adjusts the displacement of the valve core based on input electrical signals (such as 4-20mA current or ±10V voltage) to proportionally control the direction and flow of fluids. Its built-in electronic control component (OBE) and position electrical feedback ensure high precision and rapid response in control.

Typical application scenarios

This series of valves is widely used in industrial fields requiring high-precision fluid control, including:

Metallurgy and Power: Used for pressure and flow regulation in hydraulic systems.

Construction machinery: hydraulic control of equipment such as excavators and cranes.

Industrial Automation: Suitable for hydraulic machinery, production processing equipment, and automated assembly lines.

Technical Advantages and Features

High Pressure and Flow Capacity: Valves with nominal sizes 6 and 10 can withstand a maximum working pressure of 315 bar, with a flow rate capacity of up to 75 L/min.

Integrated Design: The direct-acting structure combined with integrated electronic components (OBE) simplifies system configuration and enhances reliability.

Precision Control: Achieve high-accuracy flow and direction control with a hysteresis as low as 0.3% through proportional solenoids and position feedback.

Standardized Installation: Compliant with ISO 4401 standards, facilitating panel mounting and compatibility with existing hydraulic systems.

Durability and Maintenance: The valve core is made of wear-resistant materials (such as DLC coating), ensuring a long service life and low maintenance costs.

Summary

The 4WREE series proportional valves are designed with a direct-acting mechanism, integrated electronic components, and high-precision control as their core advantages, making them suitable for fluid regulation in complex industrial environments. Their technical features include high-pressure resistance, rapid response, and standardized installation, enabling outstanding performance in fields such as metallurgy and construction machinery.

Common Model Examples

4WREE10E75-2X/G24K31/A1V: nominal size 10, with integrated electronic components (OBE), power supply voltage 24V

4WREE6E16-2X/G24K31/F1V: nominal size 6, flow rate 16L/min, power supply voltage 24V

4WREE10V1-50-2X/G24K31/A1V: nominal size 10, flow rate 50L/min

4WREE6E1-32-2X/G24K31/A1V: nominal size 6, flow rate 32L/min

4WREE10E1-2X/G24K31/A1V: nominal size 10, flow rate 25L/min

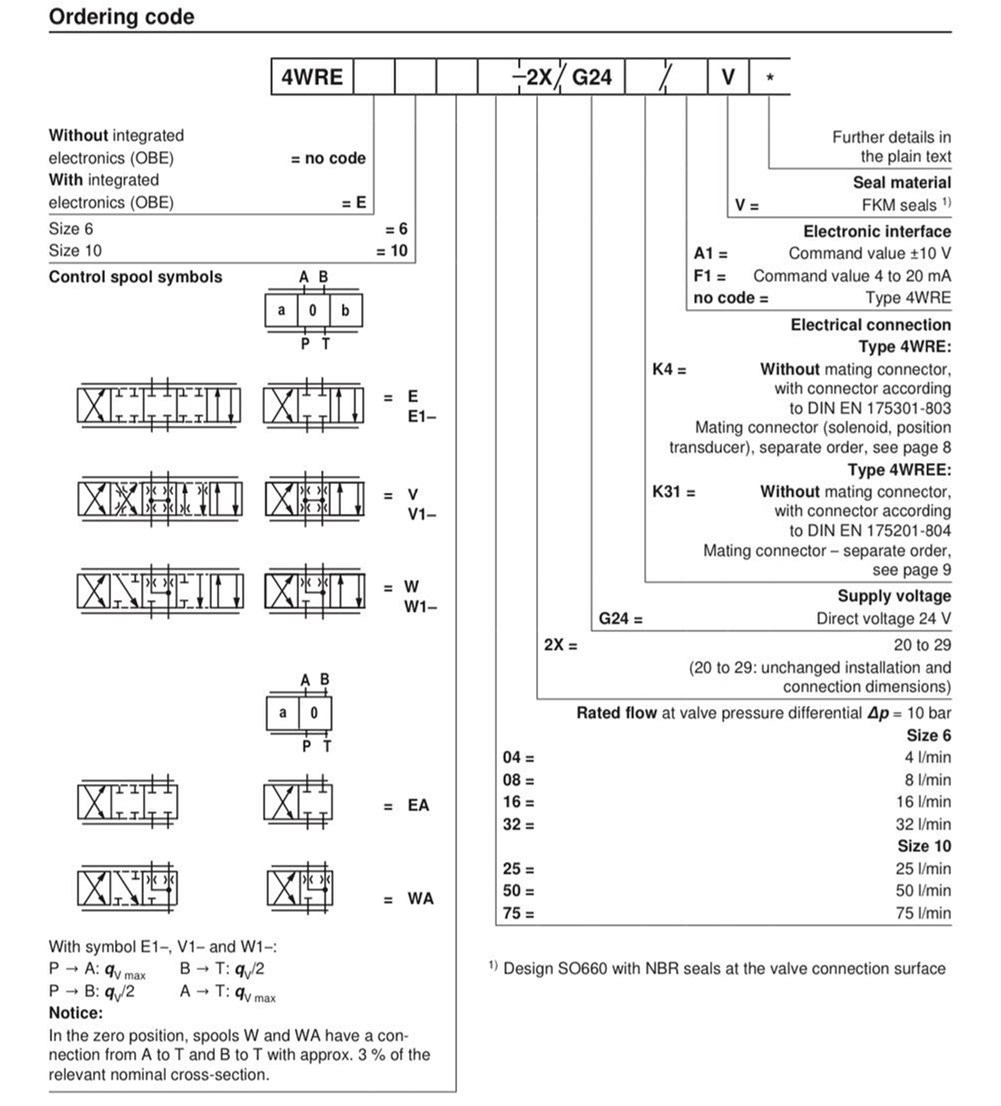

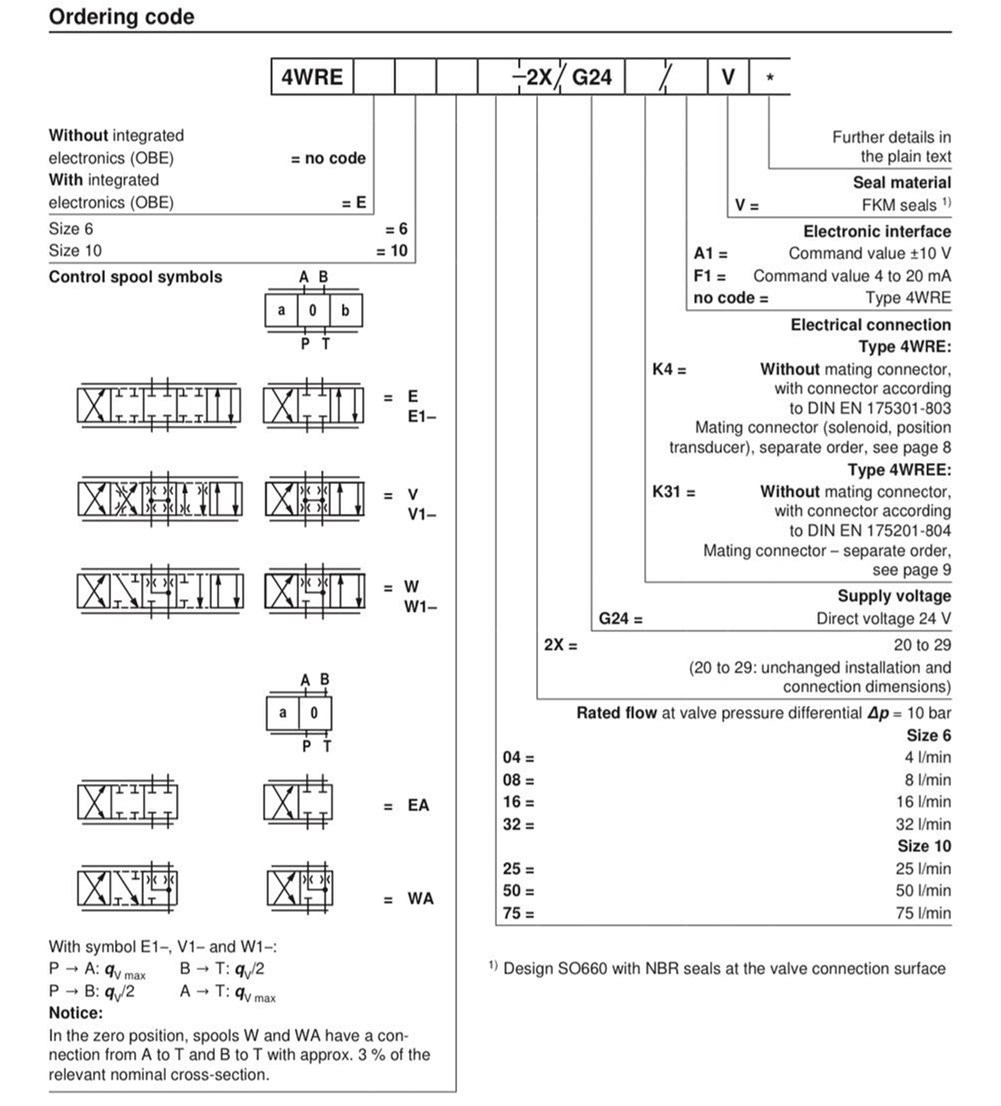

Model rules

4WREE: Series code, representing proportional directional control valves with electrical position feedback and integrated electronic devices (OBE).

Nominal size: such as 6 and 10, corresponding to different flow ranges (such as the maximum flow rate of 180L/min for the 6 series and higher for the 10 series).

Flow code: For example, E75 represents 75L/min, E1-25 represents 25L/min.

Power supply voltage: such as G24=24V.

Electrical interface: such as A1=± 10V, F1=4-20mA.

The 4WREE series proportional valve is a direct-acting proportional directional valve, with its core function being the proportional adjustment of oil flow direction and volume through integrated control electrical components (OBE). This series of valves is driven by proportional solenoids and can accept voltage or current signals to achieve precise continuous control.

Core functionality

The core function of the 4WREE series proportional valve is **proportional control**, which precisely adjusts the displacement of the valve core based on input electrical signals (such as 4-20mA current or ±10V voltage) to proportionally control the direction and flow of fluids. Its built-in electronic control component (OBE) and position electrical feedback ensure high precision and rapid response in control.

Typical application scenarios

This series of valves is widely used in industrial fields requiring high-precision fluid control, including:

Metallurgy and Power: Used for pressure and flow regulation in hydraulic systems.

Construction machinery: hydraulic control of equipment such as excavators and cranes.

Industrial Automation: Suitable for hydraulic machinery, production processing equipment, and automated assembly lines.

Technical Advantages and Features

High Pressure and Flow Capacity: Valves with nominal sizes 6 and 10 can withstand a maximum working pressure of 315 bar, with a flow rate capacity of up to 75 L/min.

Integrated Design: The direct-acting structure combined with integrated electronic components (OBE) simplifies system configuration and enhances reliability.

Precision Control: Achieve high-accuracy flow and direction control with a hysteresis as low as 0.3% through proportional solenoids and position feedback.

Standardized Installation: Compliant with ISO 4401 standards, facilitating panel mounting and compatibility with existing hydraulic systems.

Durability and Maintenance: The valve core is made of wear-resistant materials (such as DLC coating), ensuring a long service life and low maintenance costs.

Summary

The 4WREE series proportional valves are designed with a direct-acting mechanism, integrated electronic components, and high-precision control as their core advantages, making them suitable for fluid regulation in complex industrial environments. Their technical features include high-pressure resistance, rapid response, and standardized installation, enabling outstanding performance in fields such as metallurgy and construction machinery.

Common Model Examples

4WREE10E75-2X/G24K31/A1V: nominal size 10, with integrated electronic components (OBE), power supply voltage 24V

4WREE6E16-2X/G24K31/F1V: nominal size 6, flow rate 16L/min, power supply voltage 24V

4WREE10V1-50-2X/G24K31/A1V: nominal size 10, flow rate 50L/min

4WREE6E1-32-2X/G24K31/A1V: nominal size 6, flow rate 32L/min

4WREE10E1-2X/G24K31/A1V: nominal size 10, flow rate 25L/min

Model rules

4WREE: Series code, representing proportional directional control valves with electrical position feedback and integrated electronic devices (OBE).

Nominal size: such as 6 and 10, corresponding to different flow ranges (such as the maximum flow rate of 180L/min for the 6 series and higher for the 10 series).

Flow code: For example, E75 represents 75L/min, E1-25 represents 25L/min.

Power supply voltage: such as G24=24V.

Electrical interface: such as A1=± 10V, F1=4-20mA.