Professional Hydraulic Pump Manufacturer & Supplier

Senhengyuan Machinery specializes in manufacturing and supplying high-performance hydraulic pumps for diverse industrial applications. Our comprehensive product range includes hydraulic gear pumps, piston pumps, vane pumps, and custom-engineered solutions designed to meet your specific operational requirements.

As a trusted industrial hydraulic pumps manufacturer with over 10 years of experience, we provide reliable hydraulic pumps and motors for construction equipment, agricultural machinery, manufacturing systems, and mobile hydraulics applications. Our pumps are engineered for durability, efficiency, and consistent performance in demanding environments.

We offer various configurations including electric hydraulic pump models (12v hydraulic pump, 110v hydraulic pump), manual hydraulic pump options for portable applications, and specialized solutions such as dump trailer hydraulic pump and 2 stage hydraulic pump systems. Whether you need a compact mini hydraulic pump or a high flow hydraulic pump for heavy-duty operations, our technical team can recommend the optimal solution.

Factory Direct Pricing

As a direct hydraulic pump manufacturer with our own production facilities, we eliminate middleman markups and deliver competitive pricing 15-20% below market average. Our streamlined supply chain ensures you get premium quality industrial hydraulic pumps, gear pumps, and piston pumps at factory-direct rates, maximizing your project budget efficiency.

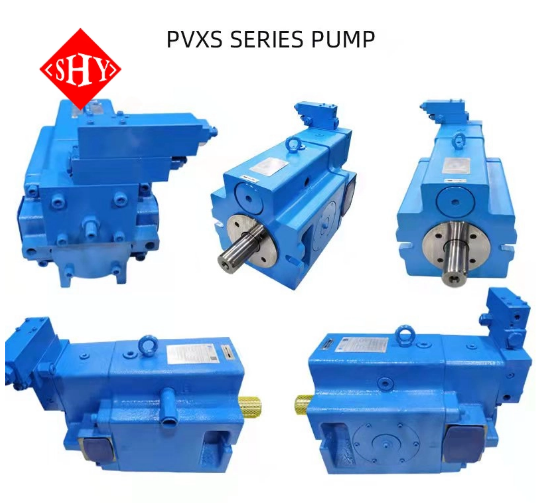

Complete Product Range

From compact 12v hydraulic pump units for mobile equipment to high-capacity industrial hydraulic pumps for heavy machinery, our extensive catalog covers gear pumps, piston pumps, vane pumps, electric and manual models. Whether you need a portable hydraulic pump, dump trailer hydraulic pump, or specialized 2-stage configurations, we provide complete hydraulic pumps and motors solutions under one roof.

Social Responsibility

Every hydraulic pump undergoes rigorous multi-point inspection including pressure testing to 1.5x rated capacity, flow accuracy verification, and 72-hour endurance trials. Our quality control system ensures each gear hydraulic pump, variable displacement hydraulic pump, and electric hydraulic pump meets international standards. All products backed by 18-month warranty and lifetime technical support.

Customer-Centric

Leverage our 10+ years engineering expertise for tailored solutions. We customize voltage options (12v/24v/110v hydraulic pumps), mounting flanges, port configurations, and performance parameters. Special applications like weatherproof trailer hydraulic pump enclosures, explosion-proof electric hydraulic pump 12v models, or integrated valve blocks on concentric hydraulic pump assemblies - all feasible with low MOQ for prototypes.

Hydraulic Pump Types: Complete Comparison Guide

Choose the right hydraulic pump for your application. We manufacture three main types: Piston Pumps for high-pressure systems, Vane Pumps for medium-pressure applications, and Gear Pumps for cost-effective solutions.

Choose Your Ideal Pump Technology

Professional hydraulic solutions engineered for durability, precision, and superior performance across industrial and mobile applications

Hydraulic Gear Pumps

Cost-effective hydraulic gear pumps engineered with precision external gear mechanisms deliver steady flow for medium-pressure mobile and industrial systems. Our gear hydraulic pump models feature aluminum or cast iron bodies, bidirectional rotation capability, and proven performance in agricultural tractors, material handling equipment, and auxiliary circuits from 5 to 200 L/min.

Piston Pumps

High-performance piston pump solutions with variable displacement control enable precise flow regulation and energy savings up to 30%. Swash plate and bent-axis designs handle extreme pressures exceeding 400 bar for excavators, presses, and offshore equipment. Our variable displacement hydraulic pump range includes load-sensing and pressure-compensated options for intelligent power management.

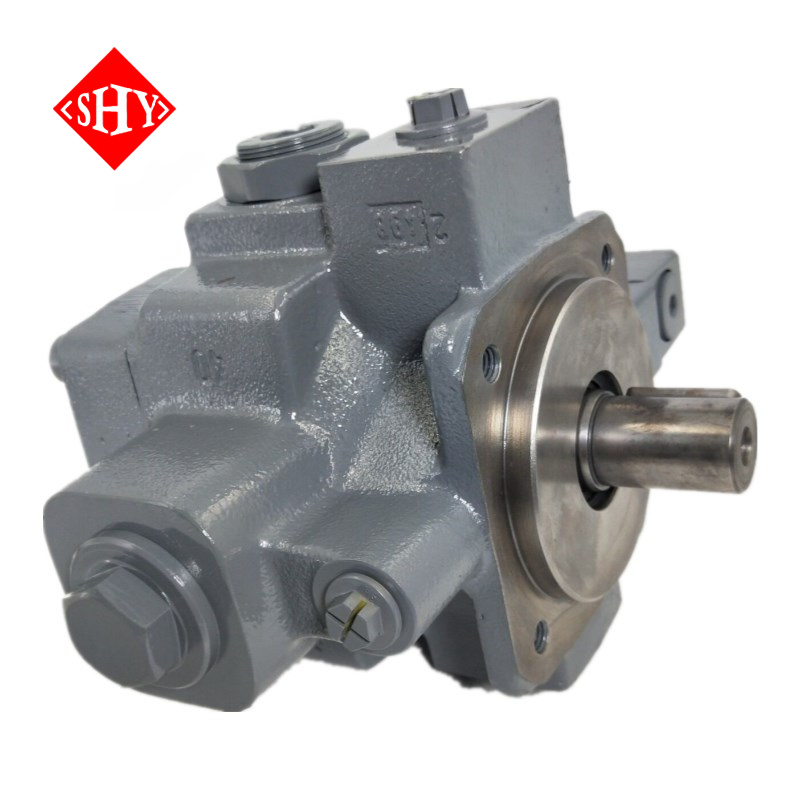

Vane Pumps

Quiet vane pump technology with balanced cartridge design minimizes vibration and noise for plastic injection molding, CNC machine tools, and precision manufacturing. Double or single vane configurations provide contamination resistance and smooth pressure delivery. Fixed and variable displacement models available with flow rates optimized for continuous-duty industrial installations requiring ultra-low sound levels.

Hydraulic Pump Technical Specifications & Performance Data

Understanding hydraulic pump specifications is critical for selecting the right equipment for your application. Our comprehensive technical data covers displacement ranges, pressure ratings, flow characteristics, and compatibility parameters across all hydraulic gear pumps, piston pump, and vane pump models. Use these specifications to match pump performance with your system requirements for optimal efficiency and reliability.

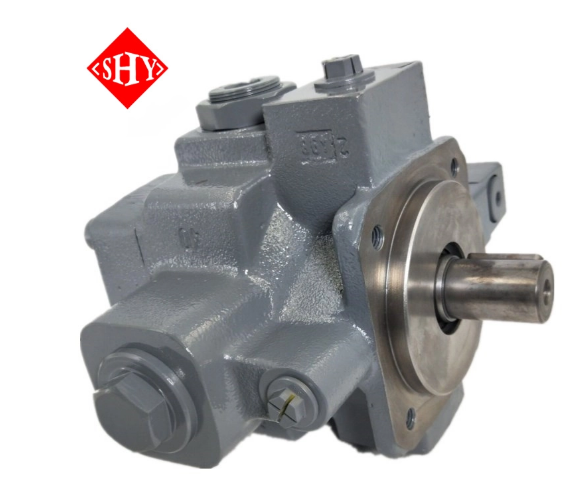

Hydraulic Gear Pump

This hydraulic gear pump features precision-machined external gears delivering consistent flow for mobile and industrial applications. Compact cast iron construction ensures reliable medium-pressure performance in tractors, loaders, and auxiliary power units with minimal maintenance requirements.

Displacement: 16-125 cc/rev

Model: CBT-F316

Pressure Rating: Maximum operating pressure up to 250 bar for demanding hydraulic systems

Flow Rate: 20-80 L/min at standard speeds

Applications: Agricultural machinery, material handling, construction equipment

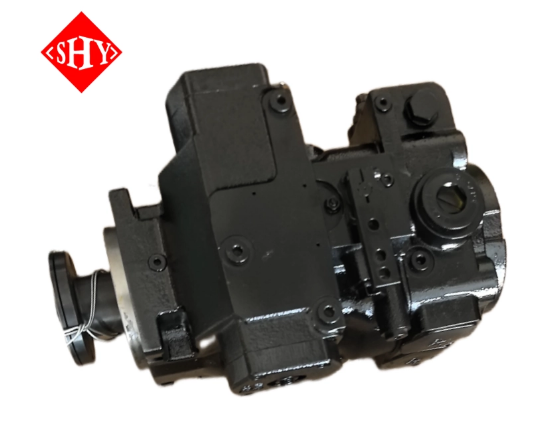

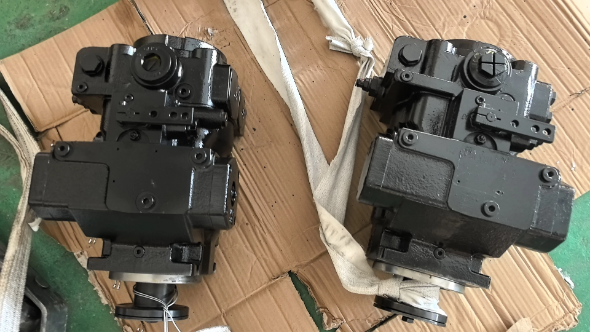

Variable Piston Pump

This variable displacement hydraulic pump provides intelligent flow control with swash plate technology for energy-efficient operation. Load-sensing capability automatically adjusts output matching system demand, reducing fuel consumption in excavators, cranes, and heavy-duty industrial machinery.

Displacement: 28-180 cc/rev (variable)

Model: A4VSO-125

Pressure Rating: High-pressure capability up to 350 bar for extreme applications

Control Type: Hydraulic pressure compensator with electric proportional option

Applications: Excavators, injection molding, offshore equipment

Electric Hydraulic Pump

This 12v hydraulic pump combines compact DC motor with integrated gear pump for portable power solutions. Weatherproof IP65 enclosure protects electronics in outdoor environments, making it ideal for dump trailer hydraulic pump systems, mobile lifts, and emergency rescue equipment applications.

Voltage: 12V DC / 24V DC options

Model: EP-12V-2.2KW

Motor Power: 2.2 kW continuous duty rated for extended operation cycles

Flow Rate: 4.5 L/min at 180 bar working pressure

Applications: Dump trailers, tailgate lifts, portable power units

Contact Us

Supported by expert hydraulic engineers providing technical guidance and complete pump solutions globally. Specializing in hydraulic gear pumps, variable displacement systems, trailer hydraulic pump units, and custom configurations, we deliver professional recommendations matching your exact system specifications and industry requirements.

Hydraulic Pump Applications Across Industries

FAQs About Hydraulic Pumps

Our Certifications & Quality Standards

SHY hydraulic pumps are manufactured under strict international quality management systems, ensuring every product meets global industry standards for safety, performance, and reliability.

Related Blogs

-

A pneumatic Piston Pump is a reciprocating positive displacement device driven by compressed air, engineered to generate high discharge pressures through mechanical amplification. While Air Operated Double Diaphragm (AODD) pumps often dominate discussions regarding volume transfer, piston technology remains the standard for handling high-viscosity materials and overcoming significant head pressure requirements. Unlike an electric centrifugal pump, these units offer a unique "stall-under-load" capability, making them intrinsically efficient for intermittent, on-demand operations.

A pneumatic Piston Pump is a reciprocating positive displacement device driven by compressed air, engineered to generate high discharge pressures through mechanical amplification. While Air Operated Double Diaphragm (AODD) pumps often dominate discussions regarding volume transfer, piston technology remains the standard for handling high-viscosity materials and overcoming significant head pressure requirements. Unlike an electric centrifugal pump, these units offer a unique "stall-under-load" capability, making them intrinsically efficient for intermittent, on-demand operations. -

The difference between a profitable hydraulic system and a money pit often comes down to the rigor of your maintenance schedule. For equipment owners, the Total Cost of Ownership (TCO) of a hydraulic unit is not defined by its sticker price, but by how long it operates before requiring a major overhaul. Neglecting a high-performance Piston Pump inevitably leads to catastrophic downtime, where the cost of lost production far exceeds the price of a replacement unit. While generic cleaning is helpful, it is not enough to secure the longevity of precision-engineered components found in modern excavators and industrial machinery.

The difference between a profitable hydraulic system and a money pit often comes down to the rigor of your maintenance schedule. For equipment owners, the Total Cost of Ownership (TCO) of a hydraulic unit is not defined by its sticker price, but by how long it operates before requiring a major overhaul. Neglecting a high-performance Piston Pump inevitably leads to catastrophic downtime, where the cost of lost production far exceeds the price of a replacement unit. While generic cleaning is helpful, it is not enough to secure the longevity of precision-engineered components found in modern excavators and industrial machinery. -

When you invest in a high-performance hydraulic system, the longevity of the heart of that system—the pump—is a primary concern. Manufacturers often provide a rated B10 lifespan, suggesting a theoretical number of hours before 10% of units might fail. However, these specification sheets rarely align perfectly with the harsh realities of the field. In practice, the lifespan of a pump is dictated less by its fatigue limit and more by application severity, fluid cleanliness, and the discipline of your maintenance schedule.

When you invest in a high-performance hydraulic system, the longevity of the heart of that system—the pump—is a primary concern. Manufacturers often provide a rated B10 lifespan, suggesting a theoretical number of hours before 10% of units might fail. However, these specification sheets rarely align perfectly with the harsh realities of the field. In practice, the lifespan of a pump is dictated less by its fatigue limit and more by application severity, fluid cleanliness, and the discipline of your maintenance schedule.

Keep In Touch With Us

Connect with SHY for real-time hydraulic pump updates, installation videos, customer success stories, and engineering tips. Join thousands of professionals discussing piston pump maintenance, trailer hydraulic pump systems, and industry best practices daily.

Mob:+86-17750579182

E-mail:senhengyuan@yeah.net