| Availability: | |

|---|---|

| Quantity: | |

90 series 90R 90L Hydraulic Axial Piston Pump | |

Product series: | |

90R | 90L |

90R030 | 90L030 |

90R042 | 90L042 |

90R055 | 90L055 |

90R075 | 90L075 |

90R100 | 90L100 |

90R130 | 90L130 |

90R180 | 90L180 |

90R250 | 90L250 |

Advantages: | |

• Compact, lightweight | |

• Efficient axial piston design | |

• Worldwide sales and service | |

• One variable displacement motor | |

• Proven reliability and performance | |

• Five sizes of fixed displacement motors | |

• SAE and cartridge mount configurations | |

• Plus+1™ compliant controls and sensors | |

• Seven sizes of variable displacement pumps | |

Series 90 hydrostatic pumps and motors can be applied together or combined with other products in a system to transfer and control hydraulic power. They are intended for closed circuit applications.

series 90 variable displacement pumps are compact, high power density units. All models utilize the parallel axial piston/slipper concept in conjunction with a tiltable swashplate to vary the pump's displacement. Reversing the angle of the swashplate reverses the flow of oil from the pump and thus reverses the direction of rotation of the motor output.

Series 90 pumps include an integral charge pump to provide system replenishing and cooling oil flow, as well as control fluid flow. They also feature a range of auxiliary mounting pads to accept auxiliary hydraulic pumps for use in complementary hydraulic systems. A complete family of control options is available to suit a variety of control systems (mechanical, hydraulic, electric).

series 90 motors also use the parallel axial piston/slipper design in conjunction with a fixed or tiltable swashplate. They can intake/discharge fluid through either port; they are bidirectional. They also include an optional loop flushing feature that provides additional cooling and cleaning of fluid in the working loop.

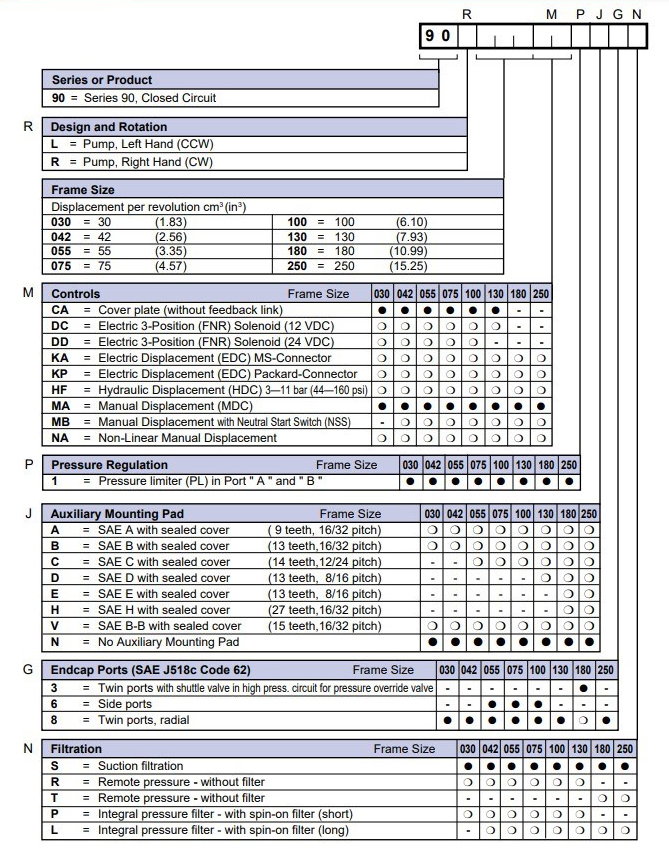

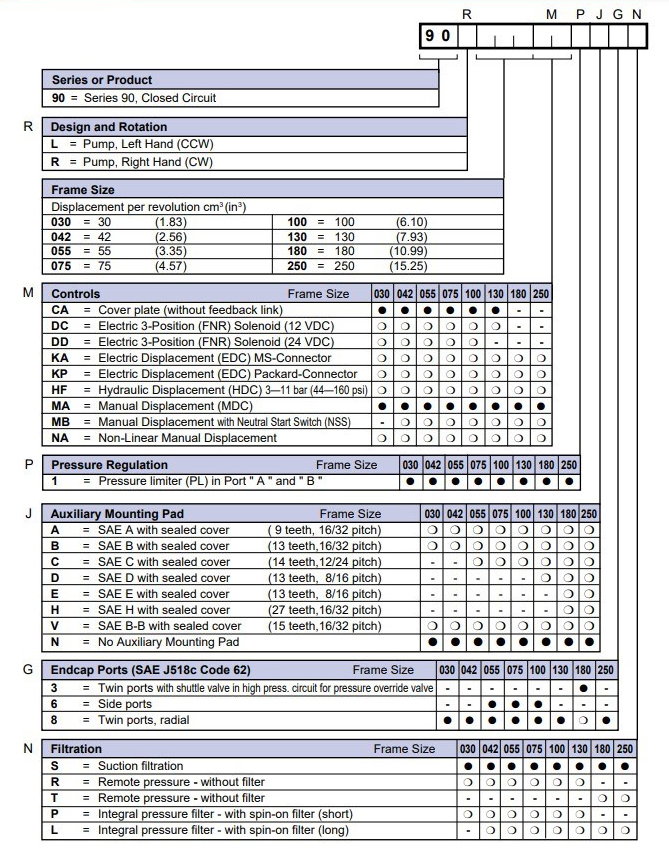

Ordering code for standard program:

A:SAE A with sealed cover,Frame Size:9 teeth, 16/32 pitch

B:SAE B with sealed cover,Frame Size:13 teeth,16/32 pitch

C:SAE C with sealed cover,Frame Size:14 teeth,12/24 pitch

D:SAE D with sealed cover,Frame Size:13 teeth, 8/16 pitch

E:SAE E with sealed cover,Frame Size:13 teeth, 8/16 pitch

H:SAE H with sealed cover,Frame Size:27 teeth,16/32 pitch

V:SAE B-B with sealed cover,Frame Size:15 teeth,16/32 pitch

3:Twin ports with shuttle valve in high press. circuit for pressure override valve

6:Side ports

8:Twin ports, radial

T4:1.750in. tapered

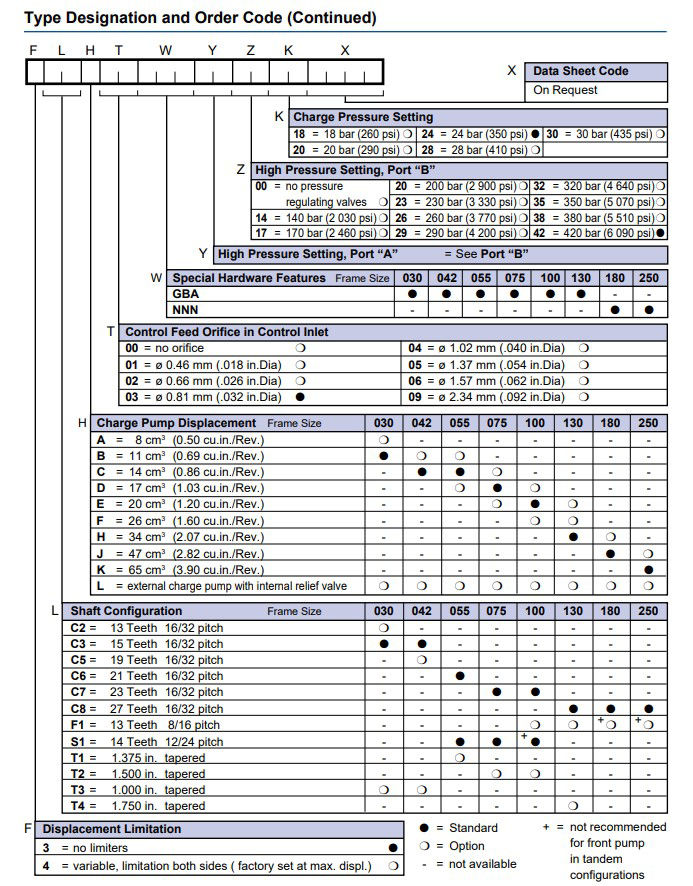

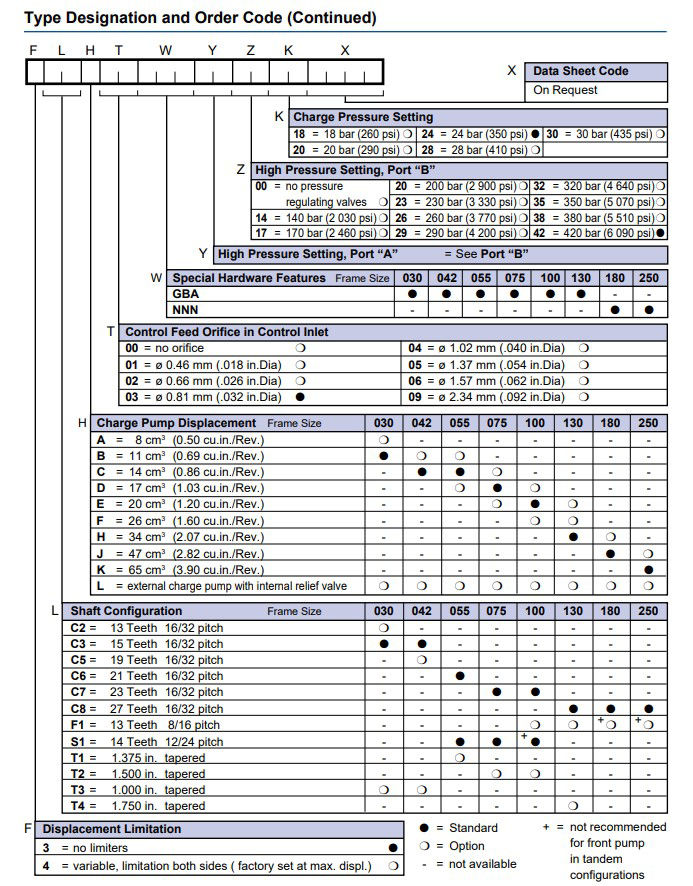

A or B or C or D or E or F or H or J or K or L:Charge Pump Displacement

09:2.34 mm (.092 in.Dia)

GBA or NNN:Special Hardware Features Frame Size

00 or 14 or 17 or 20 or 23 or 26 or 29 or 32 or 35 or 38 or 42:High Pressure Setting, Port "A"

42:420 bar (6 090 psi)

00 or 14 or 17 or 20 or 23 or 26 or 29 or 32 or 35 or 38 or 42:High Pressure Setting, Port "B”

42:420 bar (6 090 psi)

18 or 20 or 24 or 28 or 30:Charge Pressure Setting

30:30 = 30 bar(435 psi)

Feature | Unit | Frame | ||||||

042 | 055 | 075 | 100 | 130 | 180 | 250 | ||

Displacement | cm³/rev [in³]/rev | 42 [2.56] | 55 [3.35] | 75 [4.59] | 100 [6.10] | 130 [7.93] | 180 [10.98] | 250 [15.25] |

Flow at rated speed (theoretical) | l/min [US gal/min] | 176 [46] | 215 [57] | 270 [71] | 330 [87] | 403 [106] | 468 [124] | 575 [160] |

Torque at maximum displacement (theoretical) | N•m/bar [lbf•in/1000 psi] | 0.67 [410] | 0.88 [530] | 1.19 [730] | 1.59 [970] | 2.07 [1260] | 2.87 [1750] | 3.97 [2433] |

Mass moment of inertia of rotating components | kg•m² [slug•ft²] | 0.0023 [0.0017] | 0.0060 [0.0044] | 0.0096 [0.0071] | 0.0150 [0.0111] | 0.0023 [0.0170] | 0.0380 [0.0280] | 0.0650 [0.0479] |

Weight (with control opt. MA) | kg [lb] | 34 [75] | 40 [88] | 49 [108] | 68 [150] | 88 [195] | 136 [300] | 154 [340] |

Mounting (per SAE J744) | B | C | C | C | D | E | E | |

Rotation | Clockwise or Counterclockwise | |||||||

Main ports: 4-bolt split-flange (per SAE J518 code 62) | mm [in] | 19.05 [0.75] | 25.4 [1.0] | 25.4 [1.0] | 25.4 [1.0] | 31.75 [1.25] | 31.75 [1.25] | 38.1 [1.5] |

Main port configuration | Radial | Radial or axial | Radial | |||||

Case drain ports (SAE O-ring boss) | UNF thread (in.) | 0.875–14 | 1.0625–12 | 1.0625–12 | 1.0625–12 | 1.3125–12 | 1.625–12 | 1.625–12 |

Auxiliary mounting | SAE-A, B, C | SAE-A, B, C, D | SAE-A, B, C, D, E | |||||

Input speed | ||||||||

Minimum | min-1(rpm) | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

Continuous | 4200 | 3900 | 3600 | 3300 | 3100 | 2600 | 2300 | |

Maximum | 4600 | 4250 | 3950 | 3650 | 3400 | 2850 | 2500 | |

System pressure | ||||||||

Rated | bar [psi] | 420 [6000] | ||||||

Maximum | 450 [6500] | |||||||

Minimum low loop | 10 [150] | |||||||

Inlet pressure (charge inlet) | ||||||||

Minimum (continuous) | bar (abs.) [in. Hg vac.] | 0.7 [9] | ||||||

Minimum (cold start) | 0.2 [24] | |||||||

Case pressure | ||||||||

Continuous | bar [psi] | 3 [40] | ||||||

Maximum (cold start) | 5 [75] | |||||||

90 series 90R 90L Hydraulic Axial Piston Pump | |

Product series: | |

90R | 90L |

90R030 | 90L030 |

90R042 | 90L042 |

90R055 | 90L055 |

90R075 | 90L075 |

90R100 | 90L100 |

90R130 | 90L130 |

90R180 | 90L180 |

90R250 | 90L250 |

Advantages: | |

• Compact, lightweight | |

• Efficient axial piston design | |

• Worldwide sales and service | |

• One variable displacement motor | |

• Proven reliability and performance | |

• Five sizes of fixed displacement motors | |

• SAE and cartridge mount configurations | |

• Plus+1™ compliant controls and sensors | |

• Seven sizes of variable displacement pumps | |

Series 90 hydrostatic pumps and motors can be applied together or combined with other products in a system to transfer and control hydraulic power. They are intended for closed circuit applications.

series 90 variable displacement pumps are compact, high power density units. All models utilize the parallel axial piston/slipper concept in conjunction with a tiltable swashplate to vary the pump's displacement. Reversing the angle of the swashplate reverses the flow of oil from the pump and thus reverses the direction of rotation of the motor output.

Series 90 pumps include an integral charge pump to provide system replenishing and cooling oil flow, as well as control fluid flow. They also feature a range of auxiliary mounting pads to accept auxiliary hydraulic pumps for use in complementary hydraulic systems. A complete family of control options is available to suit a variety of control systems (mechanical, hydraulic, electric).

series 90 motors also use the parallel axial piston/slipper design in conjunction with a fixed or tiltable swashplate. They can intake/discharge fluid through either port; they are bidirectional. They also include an optional loop flushing feature that provides additional cooling and cleaning of fluid in the working loop.

Ordering code for standard program:

A:SAE A with sealed cover,Frame Size:9 teeth, 16/32 pitch

B:SAE B with sealed cover,Frame Size:13 teeth,16/32 pitch

C:SAE C with sealed cover,Frame Size:14 teeth,12/24 pitch

D:SAE D with sealed cover,Frame Size:13 teeth, 8/16 pitch

E:SAE E with sealed cover,Frame Size:13 teeth, 8/16 pitch

H:SAE H with sealed cover,Frame Size:27 teeth,16/32 pitch

V:SAE B-B with sealed cover,Frame Size:15 teeth,16/32 pitch

3:Twin ports with shuttle valve in high press. circuit for pressure override valve

6:Side ports

8:Twin ports, radial

T4:1.750in. tapered

A or B or C or D or E or F or H or J or K or L:Charge Pump Displacement

09:2.34 mm (.092 in.Dia)

GBA or NNN:Special Hardware Features Frame Size

00 or 14 or 17 or 20 or 23 or 26 or 29 or 32 or 35 or 38 or 42:High Pressure Setting, Port "A"

42:420 bar (6 090 psi)

00 or 14 or 17 or 20 or 23 or 26 or 29 or 32 or 35 or 38 or 42:High Pressure Setting, Port "B”

42:420 bar (6 090 psi)

18 or 20 or 24 or 28 or 30:Charge Pressure Setting

30:30 = 30 bar(435 psi)

Feature | Unit | Frame | ||||||

042 | 055 | 075 | 100 | 130 | 180 | 250 | ||

Displacement | cm³/rev [in³]/rev | 42 [2.56] | 55 [3.35] | 75 [4.59] | 100 [6.10] | 130 [7.93] | 180 [10.98] | 250 [15.25] |

Flow at rated speed (theoretical) | l/min [US gal/min] | 176 [46] | 215 [57] | 270 [71] | 330 [87] | 403 [106] | 468 [124] | 575 [160] |

Torque at maximum displacement (theoretical) | N•m/bar [lbf•in/1000 psi] | 0.67 [410] | 0.88 [530] | 1.19 [730] | 1.59 [970] | 2.07 [1260] | 2.87 [1750] | 3.97 [2433] |

Mass moment of inertia of rotating components | kg•m² [slug•ft²] | 0.0023 [0.0017] | 0.0060 [0.0044] | 0.0096 [0.0071] | 0.0150 [0.0111] | 0.0023 [0.0170] | 0.0380 [0.0280] | 0.0650 [0.0479] |

Weight (with control opt. MA) | kg [lb] | 34 [75] | 40 [88] | 49 [108] | 68 [150] | 88 [195] | 136 [300] | 154 [340] |

Mounting (per SAE J744) | B | C | C | C | D | E | E | |

Rotation | Clockwise or Counterclockwise | |||||||

Main ports: 4-bolt split-flange (per SAE J518 code 62) | mm [in] | 19.05 [0.75] | 25.4 [1.0] | 25.4 [1.0] | 25.4 [1.0] | 31.75 [1.25] | 31.75 [1.25] | 38.1 [1.5] |

Main port configuration | Radial | Radial or axial | Radial | |||||

Case drain ports (SAE O-ring boss) | UNF thread (in.) | 0.875–14 | 1.0625–12 | 1.0625–12 | 1.0625–12 | 1.3125–12 | 1.625–12 | 1.625–12 |

Auxiliary mounting | SAE-A, B, C | SAE-A, B, C, D | SAE-A, B, C, D, E | |||||

Input speed | ||||||||

Minimum | min-1(rpm) | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

Continuous | 4200 | 3900 | 3600 | 3300 | 3100 | 2600 | 2300 | |

Maximum | 4600 | 4250 | 3950 | 3650 | 3400 | 2850 | 2500 | |

System pressure | ||||||||

Rated | bar [psi] | 420 [6000] | ||||||

Maximum | 450 [6500] | |||||||

Minimum low loop | 10 [150] | |||||||

Inlet pressure (charge inlet) | ||||||||

Minimum (continuous) | bar (abs.) [in. Hg vac.] | 0.7 [9] | ||||||

Minimum (cold start) | 0.2 [24] | |||||||

Case pressure | ||||||||

Continuous | bar [psi] | 3 [40] | ||||||

Maximum (cold start) | 5 [75] | |||||||