Views: 0 Author: Site Editor Publish Time: 2025-12-30 Origin: Site

A pneumatic Piston Pump is a reciprocating positive displacement device driven by compressed air, engineered to generate high discharge pressures through mechanical amplification. While Air Operated Double Diaphragm (AODD) pumps often dominate discussions regarding volume transfer, piston technology remains the standard for handling high-viscosity materials and overcoming significant head pressure requirements. Unlike an electric centrifugal pump, these units offer a unique "stall-under-load" capability, making them intrinsically efficient for intermittent, on-demand operations.

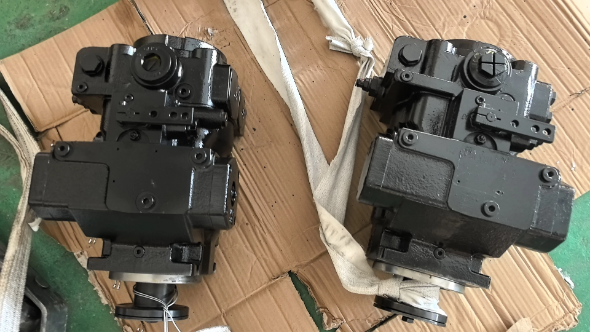

It is crucial to distinguish this industrial technology from a hydraulic piston pump found in heavy machinery. While both utilize reciprocating pistons, the drive medium defines their application scope: pneumatic pumps use compressed air for explosion-proof fluid handling in factories, whereas hydraulic versions use pressurized oil for mechanical force in mobile equipment. This article details the internal mechanics, the physics of the "Area Ratio," configuration types like chop-checks, and commercial evaluation metrics for procurement managers.

The Power Source: Utilizes a differential area ratio between the air motor and fluid plunger to amplify input air pressure by up to 100:1 (generating up to 6,000+ PSI).

Efficiency Profile: Features "Stall-under-load" capability, meaning the pump stops consuming energy when the valve closes, unlike electric pumps that require bypass loops.

Versatility: The only viable pneumatic solution for non-pourable fluids (grease, mastics, offset inks) exceeding 1 million cPs.

Safety & Compliance: Inherently explosion-proof (no electrical sparks) and ideal for ATEX/hazardous environments.

To understand the utility of a pneumatic piston pump, you must look past the external housing and examine the two distinct sections: the air motor (the engine) and the fluid section (the muscle). These two components work in tandem to convert low-pressure shop air into high-pressure fluid output.

The air motor sits at the top of the assembly. It receives compressed air from the facility's supply line. Inside this motor, a critical component known as the shuttle valve or spool valve dictates operation. This mechanism automatically alternates the airflow, directing it first to the top of the air piston and then to the bottom. This switching creates a continuous reciprocating motion—up and down—without requiring complex electrical controls or external limit switches.

One operational challenge in pneumatics is the rapid expansion of air, which causes a temperature drop. If the air supply contains moisture, ice can form on the exhaust port. Modern air motors incorporate specialized exhaust designs to minimize this icing risk, ensuring the pump cycles reliably even during rapid, continuous operation.

The defining characteristic of this technology is pressure amplification. This is governed by a simple physics formula: $$P_{fluid} = P_{air} \times (A_{air} / A_{fluid})$$. The "Area Ratio" compares the effective surface area of the large air piston to the small fluid plunger.

Imagine a large air piston with a surface area of 10 square inches connected to a fluid plunger with an area of 1 square inch. If you apply 100 PSI of air pressure, the force generated is concentrated onto the smaller plunger. This creates a multiplier effect of 10:1. Consequently, the fluid discharges at 1,000 PSI. Industrial units often achieve ratios up to 100:1, allowing them to output 6,000 PSI or more from standard shop air. This concept is similar to a hypodermic syringe: a broad thumb press generates intense pressure at the needle tip, capable of pushing thick fluids through narrow spaces.

The pump moves fluid through a two-stroke cycle. This reciprocating action creates the flow:

Suction Stroke (Upstroke): As the air motor pulls the piston rod upward, the fluid plunger lifts. This movement creates a partial vacuum in the lower chamber. The pressure differential forces the inlet valve (often called a foot valve) to open, admitting material into the pump cylinder. Simultaneously, the outlet valve (check valve) on the piston seals shut, preventing backflow.

Discharge Stroke (Downstroke): The air motor drives the piston down. This mechanical force slams the inlet valve shut. The descending piston pushes the fluid trapped in the cylinder through the outlet valve, also known as the traveling valve.

The result is a pulsated flow. While not as smooth as a rotary pump, this pulsation generates strong shear forces. These forces are essential for breaking down thixotropic materials and moving heavy, non-flowing substances through long piping runs.

Not all piston pumps serve the same purpose. Engineers select specific configurations based on fluid viscosity and application requirements. The architecture of the lower fluid section determines whether the pump moves light solvents or heavy greases.

| Pump Type | Viscosity Range | Typical Materials | Primary Mechanism |

|---|---|---|---|

| 2-Ball / 4-Ball | Low to Medium | Stains, solvents, light oils, varnishes | Gravity-fed ball checks; high cycle rates. |

| Chop-Check | High to Extreme | Mastics, sealants, heavy grease, offset ink | Priming piston (shovel) forces material in. |

| Wellhead | Variable (Groundwater) | Leachate, contaminated water | Drive motor separated from down-hole fluid section. |

These units are the industry standard for finishing and general transfer. They rely on simple ball check valves. 2-ball pumps are effective for consistent fluids. 4-ball designs are "double-acting," meaning they generate flow on both the upstroke and the downstroke. This design reduces pulsation significantly, making them ideal for circulating paint systems where steady pressure is vital for a quality finish.

When materials are too thick to flow under gravity—think peanut butter consistency—standard ball checks fail. Chop-check pumps solve this. They feature a "priming piston" or "shovel" at the foot valve. This mechanical scoop physically forces the thick material into the pump cylinder during the downstroke. For these systems to function, you almost always need a Ram Unit or a Follower Plate. The plate presses down on the material in the drum, preventing cavitation and ensuring no air pockets interrupt the flow.

A niche but critical application involves environmental cleanup. In these setups, the pump architecture separates the drive mechanism from the fluid section. A pneumatic motor remains above ground, while a long fiberglass drive rod extends down the well to actuate the piston. This allows the safe pumping of hazardous landfill leachate or groundwater without exposing the air motor to the fluid, ensuring compliance with environmental regulations.

Procurement managers must look beyond the initial purchase price. The Total Cost of Ownership (TCO) of a pneumatic piston system often outperforms alternatives when energy and maintenance are factored in.

The most significant economic advantage is the "stall" feature. When an operator releases a spray gun trigger or closes a valve, the discharge pressure equalizes with the air motor force. The pump stops dead—it stalls. In this state, it consumes zero energy. Electric pumps, by comparison, must keep spinning, relying on bypass loops to recirculate fluid, which wastes electricity and heats the material. For intermittent applications, the pneumatic piston pump offers intrinsic "on-demand" efficiency.

If your application needs pressure, AODD pumps fall short, typically maxing out around 125 PSI. Rotary gear pumps can go higher but struggle with abrasives. Piston pumps dominate the high-pressure landscape. This capability allows facilities to use longer hoses, which improves logistical efficiency in shipyards or construction sites. It also provides the necessary force for atomizing high-solids coatings in spray finishing, resulting in better surface quality and less reworked product.

Safety is a non-negotiable metric in chemical handling. Pneumatic motors operate without electricity, removing the risk of sparks. This makes them inherently suitable for Class 1 Div 1 environments, such as paint kitchens or solvent transfer zones. Furthermore, the expansion of compressed air creates a natural cooling effect on the motor. Unlike electric motors that can overheat and fail under heavy load, a pneumatic motor runs cooler the harder it works.

Deploying these pumps requires awareness of their physical behaviors. They are powerful, but they introduce specific dynamics into a fluid system.

Reciprocating motion creates pressure spikes. At the top and bottom of each stroke, flow momentarily stops as the valve shifts. This creates a "water hammer" effect in the pipes. In sensitive metering or spray applications, this pulsation causes inconsistent coverage. The fix is engineering, not magic: you must install pulsation dampeners or surge suppressors at the outlet to smooth the flow profile.

Pneumatic motors are loud. The high-velocity exhaust air can exceed safe decibel levels for nearby workers. Operational reality dictates the use of high-quality mufflers to dampen the sound. In cold environments, this exhaust can also freeze, so air line dryers are often necessary to keep the supply air dry and the pump running smoothly.

The upfront capital expenditure for an industrial Piston Pump is higher than a simple centrifugal unit, often ranging from $2,000 to over $10,000 for high-ratio extrusion packages. However, the consumables—packings and seals—are predictable wear parts. With proper preventative maintenance, the metal hard parts often last 5–10 years. The hidden cost to watch is compressed air. Air is an expensive utility. Leaking hoses or an inefficient compressor can destroy your ROI, so system integrity is paramount.

Pneumatic piston pumps are not general-purpose water movers; they are specialized heavy lifters designed for high-pressure, high-viscosity, and hazardous industrial challenges. They bridge the gap where diaphragm pumps lack pressure and electric pumps lack safety or torque.

When selecting a pump, use this decision rubric: If your application requires discharge pressures exceeding 150 PSI, involves materials thicker than honey (up to 1 million cPs), or operates in an explosion-risk zone, this technology is likely your superior option. Do not merely buy off the shelf. Calculate your required pressure ratio carefully and verify chemical compatibility for all wetted parts.

Your next step is to audit your material viscosity and required flow rate. Consult with manufacturers to match the air motor size to your available compressor capacity, ensuring you get the performance you pay for without starving the rest of your plant's air supply.

A: The primary difference lies in the drive medium. A pneumatic pump uses compressed air to drive the motor, making it ideal for factories requiring spark-free safety. Conversely, an Excavator piston pump is a Hydraulic piston pump that uses pressurized oil. Hydraulic versions are typically used in heavy mobile machinery to generate massive mechanical force, whereas pneumatic versions are used for fluid transfer and dispensing.

A: Icing occurs because expanding compressed air cools rapidly (thermodynamics). If your air supply contains moisture, this drop in temperature causes water vapor to freeze at the exhaust port. To prevent this, install an air dryer in your compressor line or use a pump designed with anti-icing exhaust geometry.

A: Generally, yes, but not indefinitely. Unlike some rotary pumps that destroy themselves instantly without liquid, piston pumps can run dry for short periods without catastrophic failure. However, prolonged dry running will eventually generate heat and friction that damages the packings and seals, leading to premature maintenance needs.

A: These pumps boast high volumetric efficiency, typically exceeding 90%. Because they are positive displacement devices, they move a fixed volume of fluid per cycle with very little "slip," unlike centrifugal pumps. This makes them highly effective for metering applications where consistent output is required.

A: You should use a follower plate when pumping non-flowable, high-viscosity materials like grease, heavy inks, or mastics. The plate rests on top of the material in the drum, creating a vacuum seal. It forces the material down into the pump inlet, preventing cavitation and ensuring the pump does not suck in air.