| Availability: | |

|---|---|

| Quantity: | |

Poduct Overview

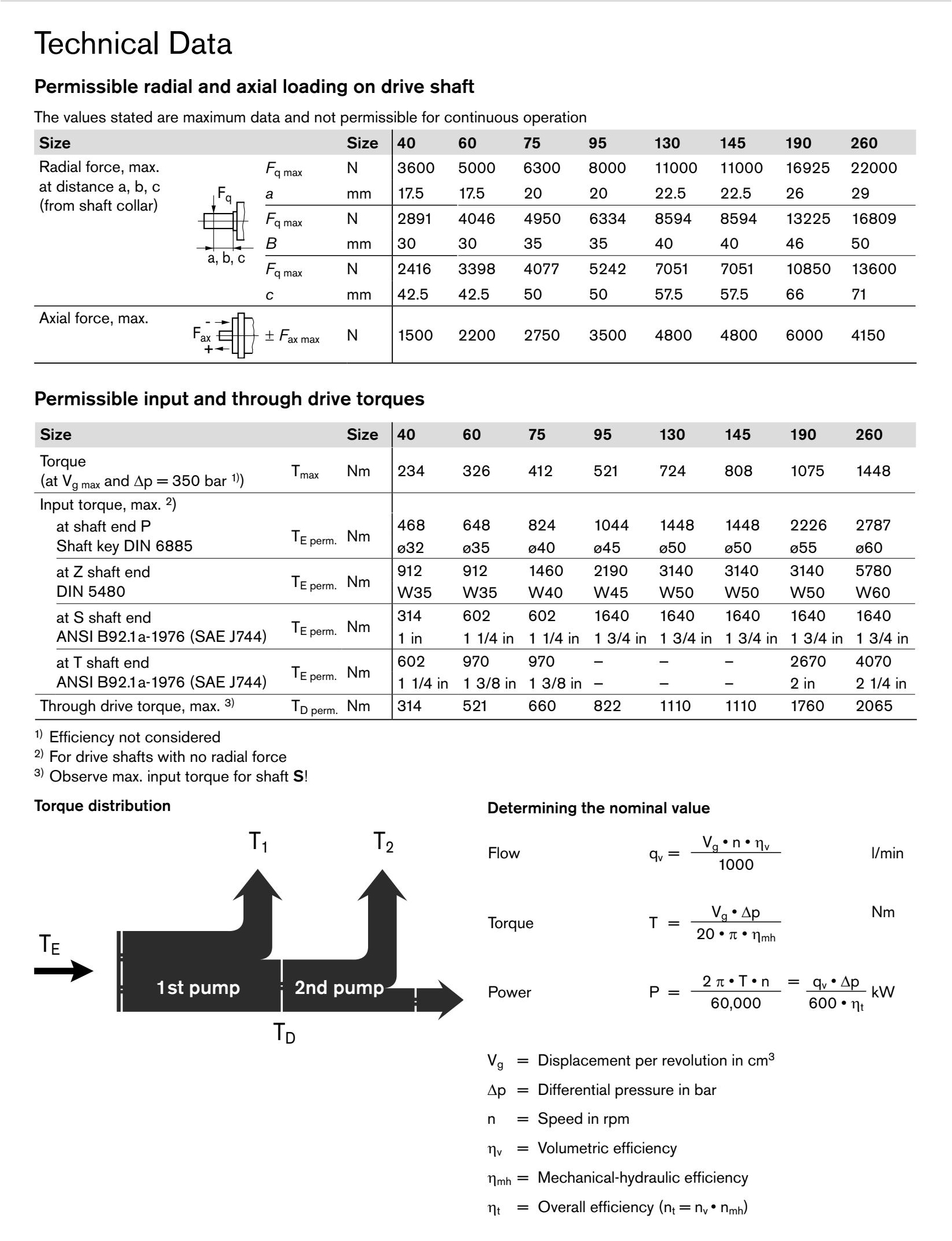

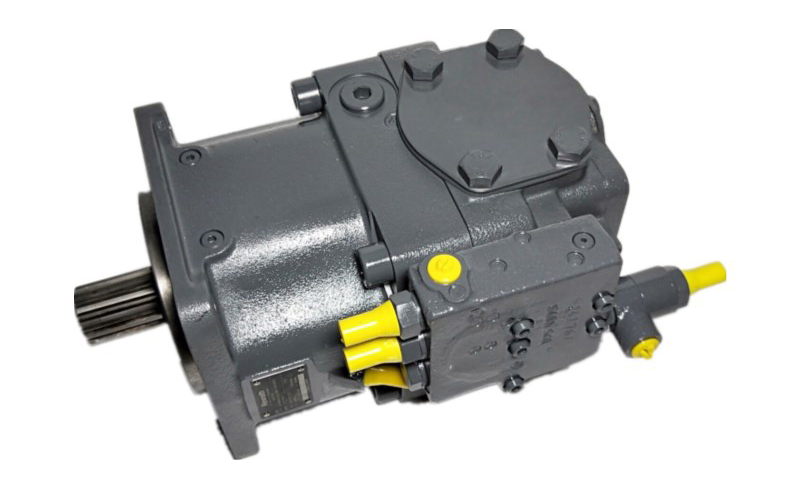

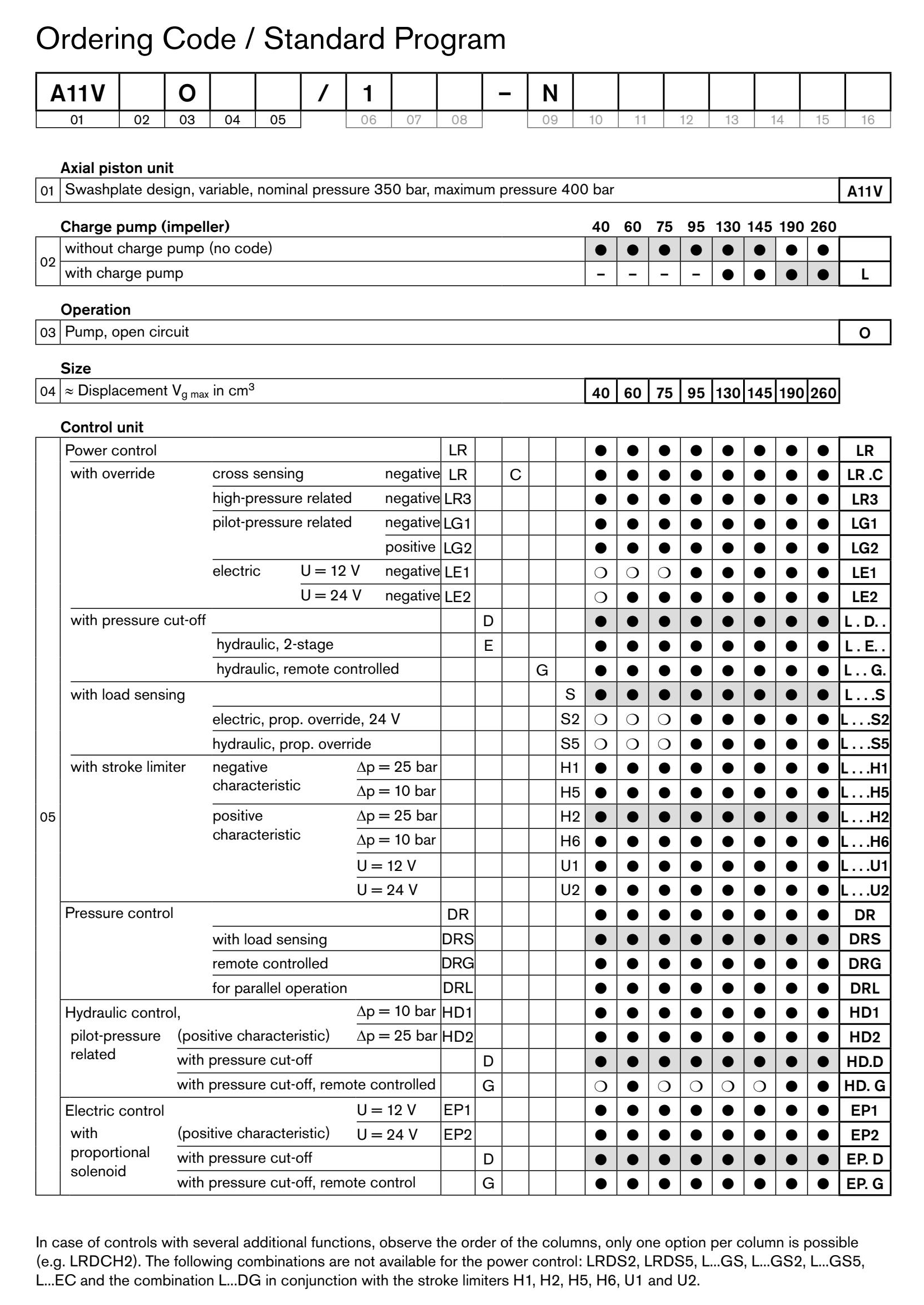

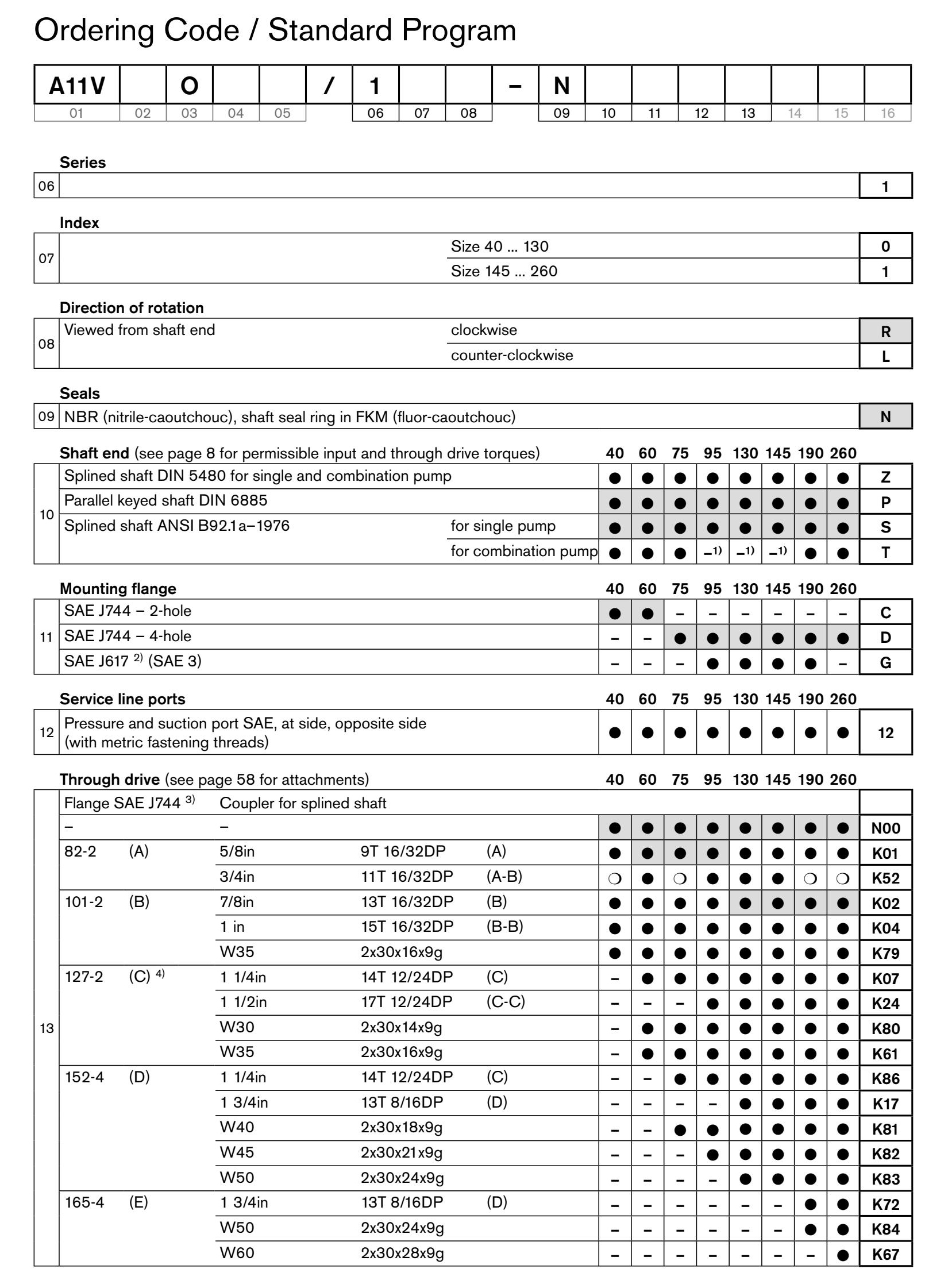

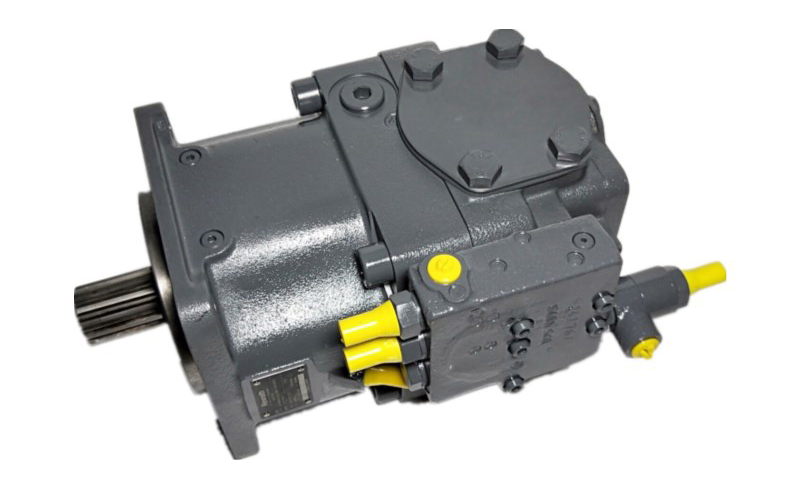

The High-pressure A11V(L)O 40-260 Axial Pump is a versatile axial piston pump engineered for high-power hydraulic systems (output power up to 150 kW), designed to handle heavy loads in industrial and mobile applications. Covering a broad displacement range from 40 cc to 260 cc, this pump delivers exceptional performance across diverse industrial sectors—from mining to marine. Its variable displacement design, controlled via a swashplate mechanism (with optional manual, hydraulic, or electro-proportional control), allows for precise flow regulation (from 5% to 100% of nominal flow), making it suitable for both open-loop (e.g., conveyor drives) and closed-loop (e.g., vehicle traction systems) circuits. It operates stably in ambient temperatures from -25°C to 85°C and can tolerate fluid contamination up to ISO 4413 class 23/21/18, ensuring reliability in dusty mining sites and humid marine environments.

Product Features

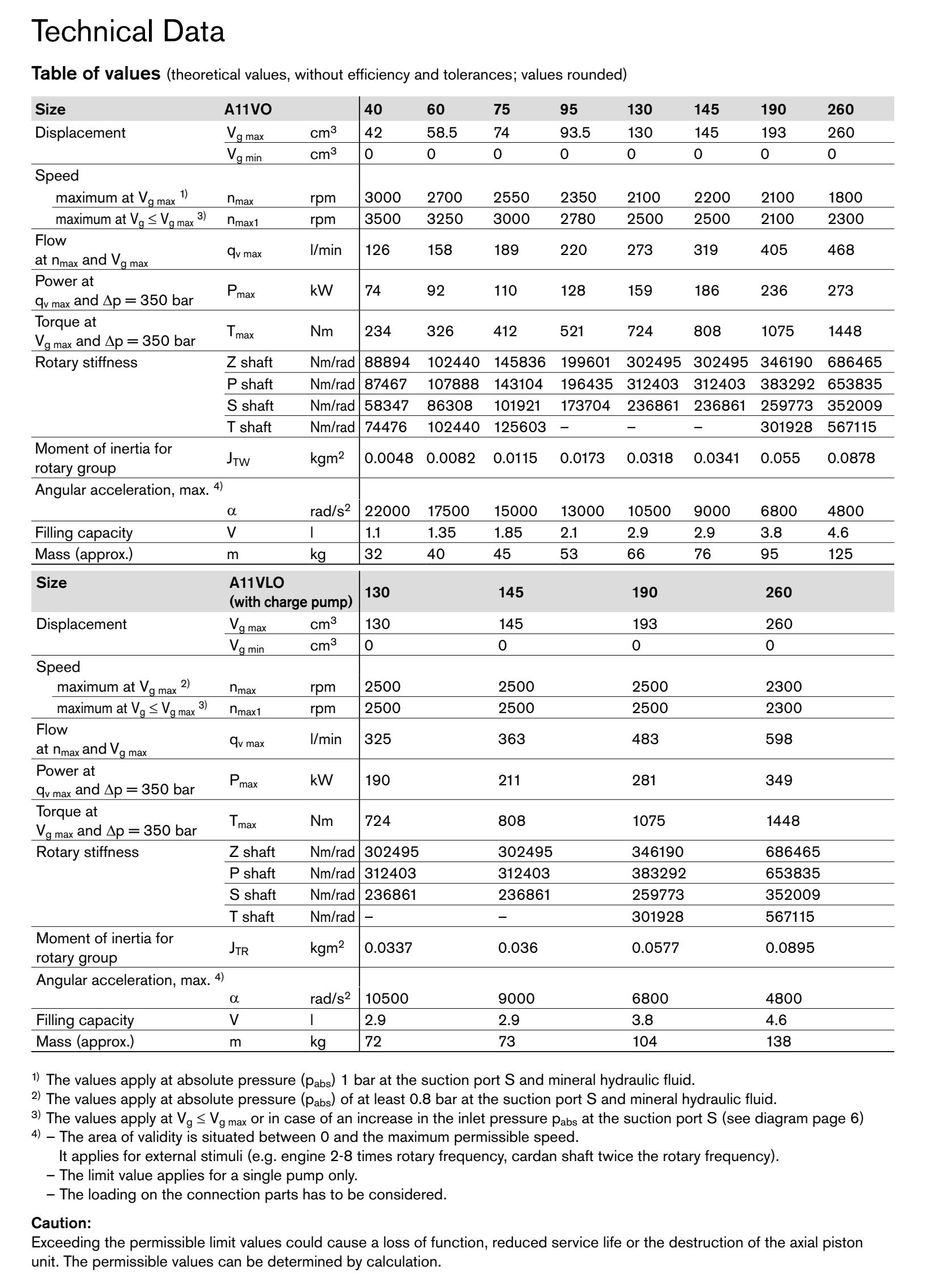

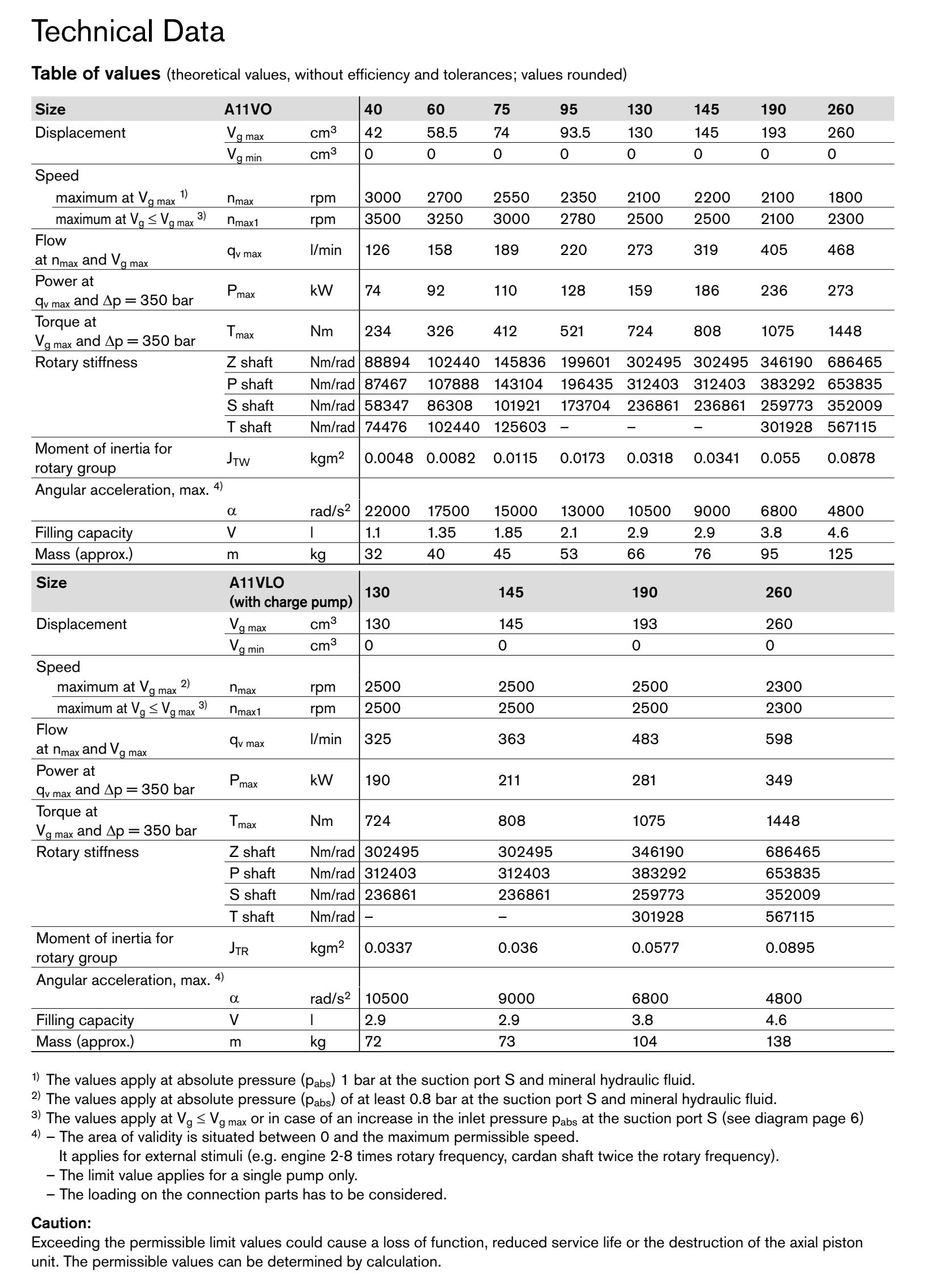

Wide Displacement Range: Available in 40 cc, 60 cc, 75 cc, 95 cc, 130 cc, 145 cc, 190 cc, and 260 cc variants—each optimized for specific power demands. The 40 cc model powers small industrial robots, while the 260 cc variant drives large mining crusher hydraulic systems, ensuring precise matching to system flow requirements .

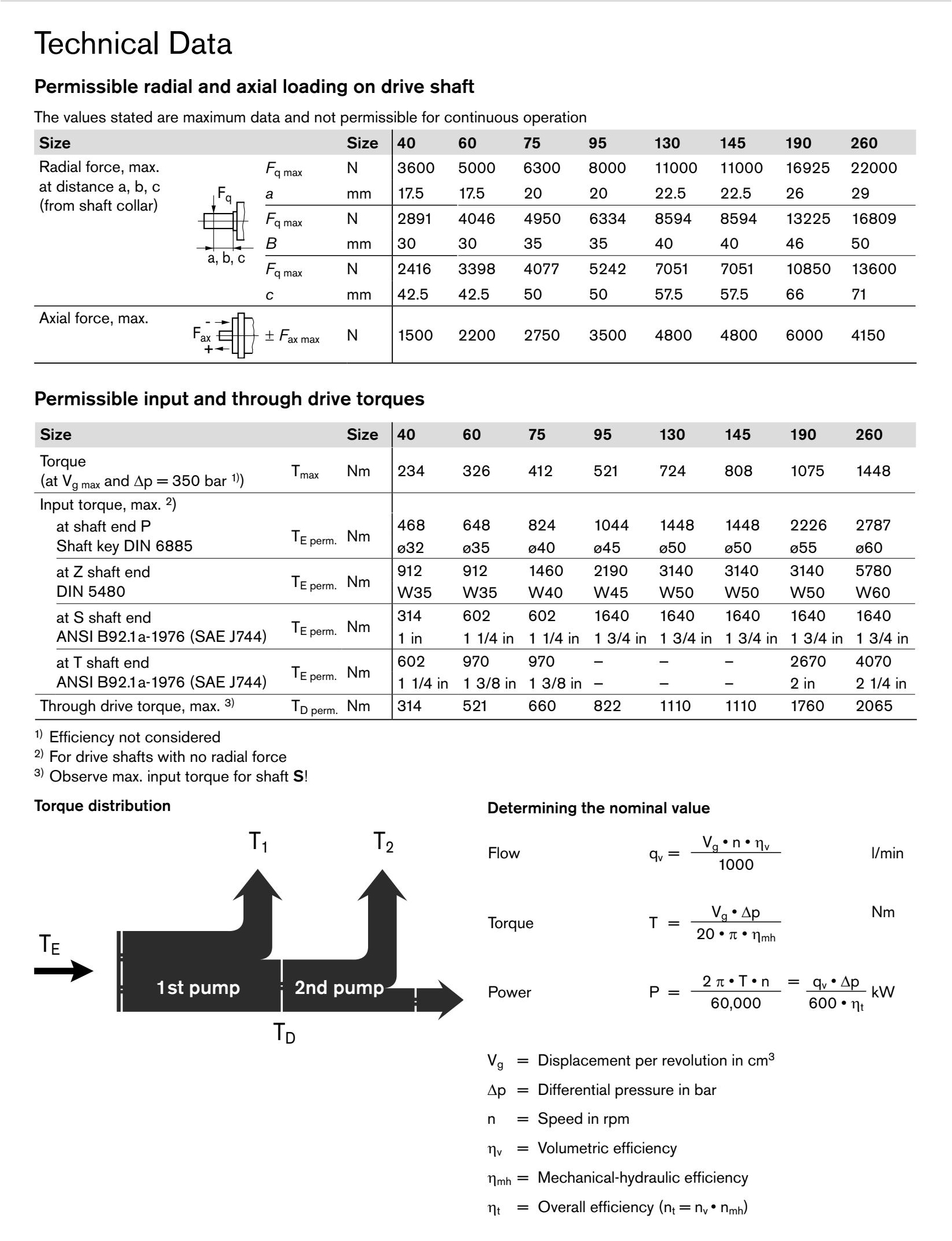

High Pressure Capability: Operates at continuous pressures up to 350 bar (5,076 psi) with short-term peaks reaching 420 bar (6,091 psi)—supporting heavy-load operations like 2,000-ton metal forging presses and 500-ton marine ship lifts. The pump’s swashplate, made of hardened steel (HRC 58-60), resists wear even under continuous high-pressure use .

Superior Efficiency: Volumetric efficiency exceeds 95% at rated pressure (350 bar) and 1800 rpm, while mechanical efficiency reaches 97%—minimizing energy loss and operational costs. For example, a 190 cc model operating at 350 bar and 1800 rpm consumes 12% less energy than comparable axial pumps (e.g., Rexroth A10VSO series) .

Rugged Design: Ductile iron housing (EN-GJS-400-15) with a tensile strength of 400 MPa resists impact and vibration, while chrome-plated pistons (10 μm thick) and nitrided cylinder bores (surface hardness: 1000 HV) ensure resistance to corrosion and wear. The pump also features a double-row angular contact bearing (SKF 3208A) that accommodates radial loads up to 25 kN .

Applications

Widely used in mining machinery (crusher hydraulic systems, grinding mill lubrication circuits), marine propulsion units (small ship hydraulic propellers, tugboat thruster drives), large-scale injection molding machines (1,000-ton clamp force molders, PET preform injection machines), and steel mill hydraulic presses (hot forging presses, cold stamping lines). Its ability to handle high flow rates (up to 400 L/min at 1800 rpm for the 260 cc model) makes it ideal for powering hydraulic motors in conveyor systems (bulk coal transport) and industrial robots (heavy-duty palletizing robots with 500 kg payloads).

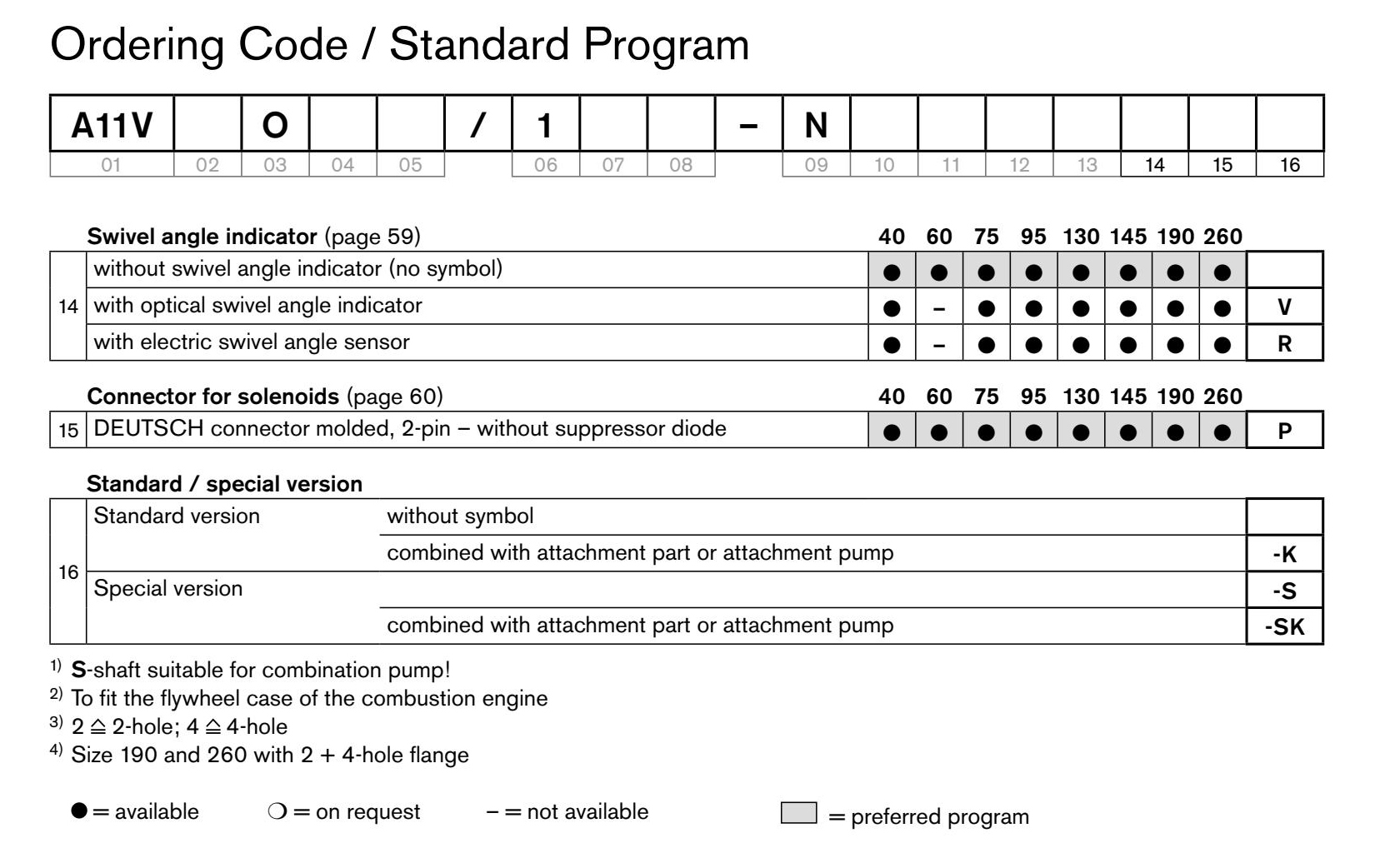

A11V(L)O series 1x A11V(L)O40 A11V(L)O60 A11V(L)O75 A11V(L)O95 A11V(L)O130

A11V(L)O145 A11V(L)O190 A11V(L)O260 Hydraulic Plunger Pump

All-purpose high pressure pump

Size 40 to 260

Nominal pressure 350 bar

Maximum pressure 400 bar

Open circuit

Features

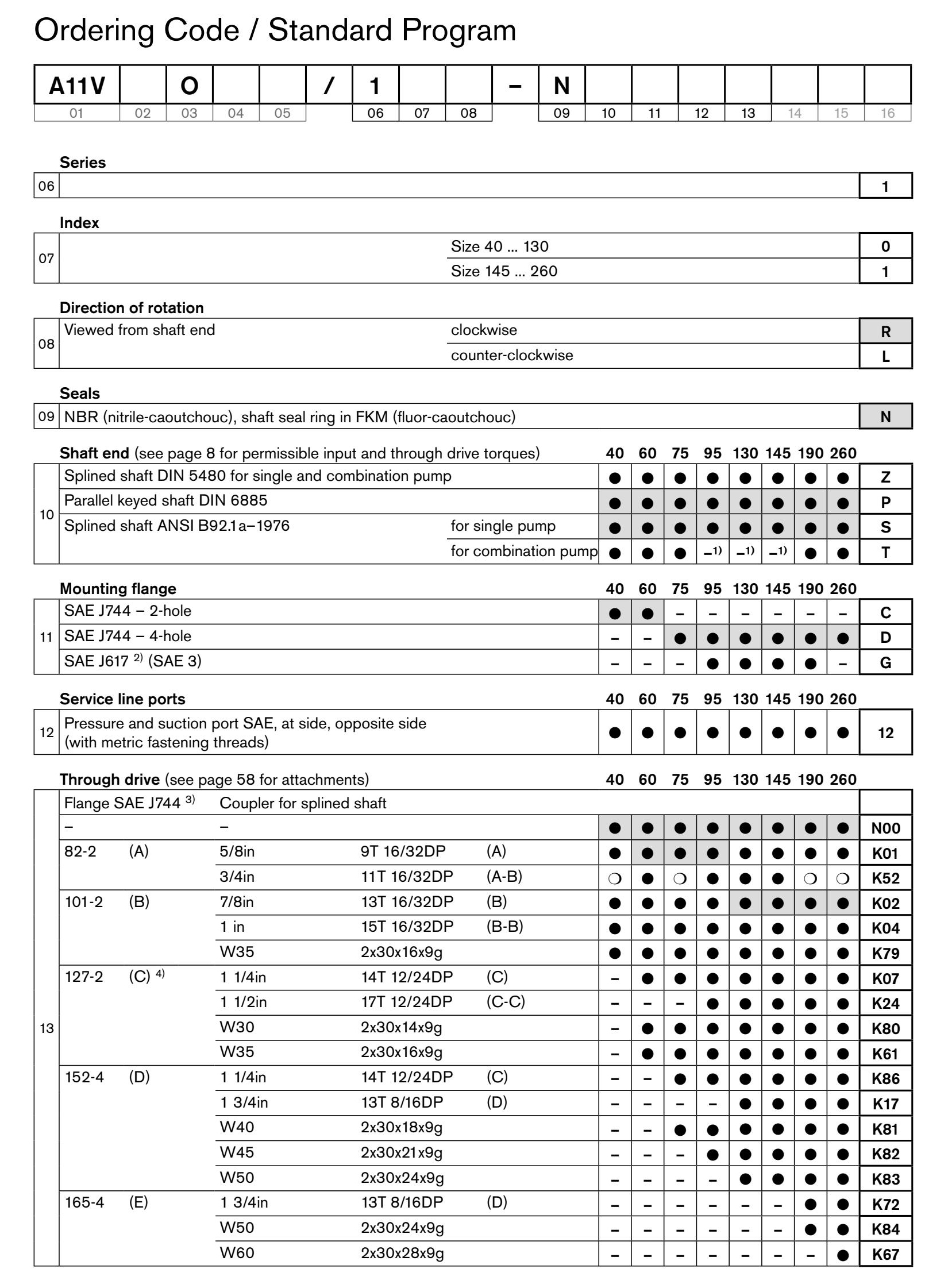

Through-drive for mounting of further pumps up to same size

Optional with charge pump for sizes 130 to 260

Higher speeds are possible for the version with charge pump (A11VLO)

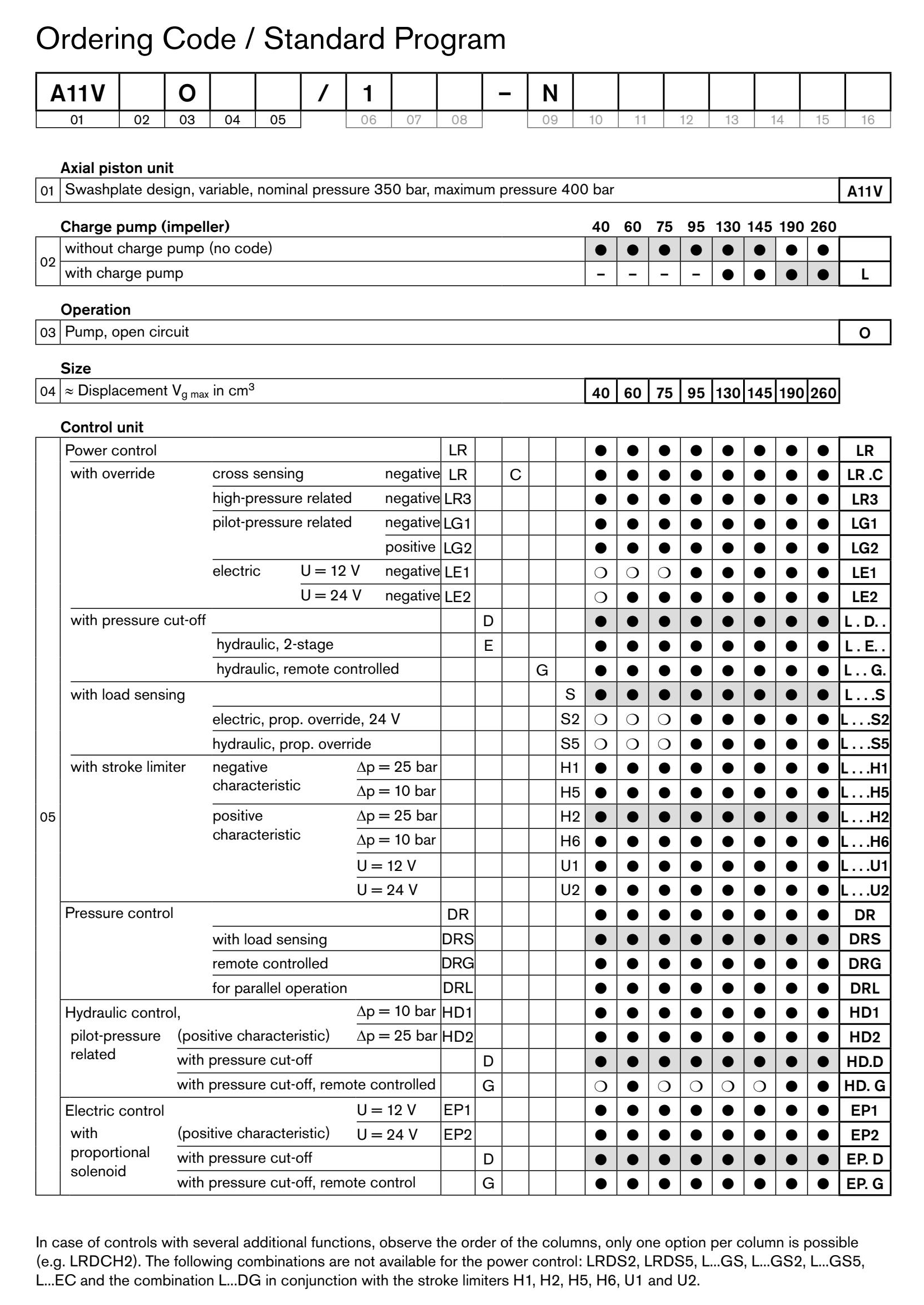

Large variety of controls

Swashplate design

Compact design

High efficiency

High power density

Poduct Overview

The High-pressure A11V(L)O 40-260 Axial Pump is a versatile axial piston pump engineered for high-power hydraulic systems (output power up to 150 kW), designed to handle heavy loads in industrial and mobile applications. Covering a broad displacement range from 40 cc to 260 cc, this pump delivers exceptional performance across diverse industrial sectors—from mining to marine. Its variable displacement design, controlled via a swashplate mechanism (with optional manual, hydraulic, or electro-proportional control), allows for precise flow regulation (from 5% to 100% of nominal flow), making it suitable for both open-loop (e.g., conveyor drives) and closed-loop (e.g., vehicle traction systems) circuits. It operates stably in ambient temperatures from -25°C to 85°C and can tolerate fluid contamination up to ISO 4413 class 23/21/18, ensuring reliability in dusty mining sites and humid marine environments.

Product Features

Wide Displacement Range: Available in 40 cc, 60 cc, 75 cc, 95 cc, 130 cc, 145 cc, 190 cc, and 260 cc variants—each optimized for specific power demands. The 40 cc model powers small industrial robots, while the 260 cc variant drives large mining crusher hydraulic systems, ensuring precise matching to system flow requirements .

High Pressure Capability: Operates at continuous pressures up to 350 bar (5,076 psi) with short-term peaks reaching 420 bar (6,091 psi)—supporting heavy-load operations like 2,000-ton metal forging presses and 500-ton marine ship lifts. The pump’s swashplate, made of hardened steel (HRC 58-60), resists wear even under continuous high-pressure use .

Superior Efficiency: Volumetric efficiency exceeds 95% at rated pressure (350 bar) and 1800 rpm, while mechanical efficiency reaches 97%—minimizing energy loss and operational costs. For example, a 190 cc model operating at 350 bar and 1800 rpm consumes 12% less energy than comparable axial pumps (e.g., Rexroth A10VSO series) .

Rugged Design: Ductile iron housing (EN-GJS-400-15) with a tensile strength of 400 MPa resists impact and vibration, while chrome-plated pistons (10 μm thick) and nitrided cylinder bores (surface hardness: 1000 HV) ensure resistance to corrosion and wear. The pump also features a double-row angular contact bearing (SKF 3208A) that accommodates radial loads up to 25 kN .

Applications

Widely used in mining machinery (crusher hydraulic systems, grinding mill lubrication circuits), marine propulsion units (small ship hydraulic propellers, tugboat thruster drives), large-scale injection molding machines (1,000-ton clamp force molders, PET preform injection machines), and steel mill hydraulic presses (hot forging presses, cold stamping lines). Its ability to handle high flow rates (up to 400 L/min at 1800 rpm for the 260 cc model) makes it ideal for powering hydraulic motors in conveyor systems (bulk coal transport) and industrial robots (heavy-duty palletizing robots with 500 kg payloads).

A11V(L)O series 1x A11V(L)O40 A11V(L)O60 A11V(L)O75 A11V(L)O95 A11V(L)O130

A11V(L)O145 A11V(L)O190 A11V(L)O260 Hydraulic Plunger Pump

All-purpose high pressure pump

Size 40 to 260

Nominal pressure 350 bar

Maximum pressure 400 bar

Open circuit

Features

Through-drive for mounting of further pumps up to same size

Optional with charge pump for sizes 130 to 260

Higher speeds are possible for the version with charge pump (A11VLO)

Large variety of controls

Swashplate design

Compact design

High efficiency

High power density