| Availability: | |

|---|---|

| Quantity: | |

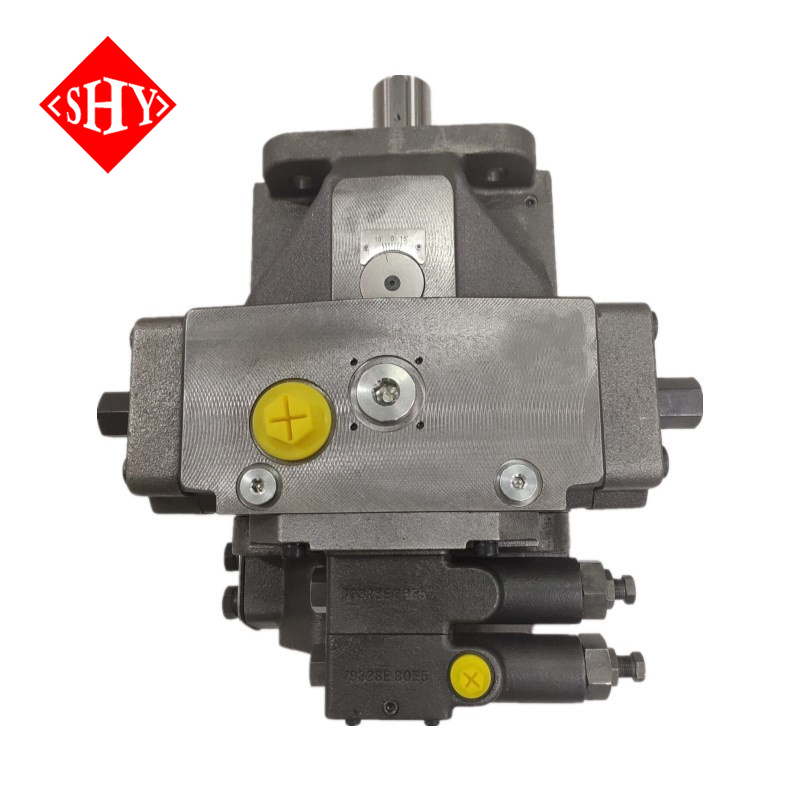

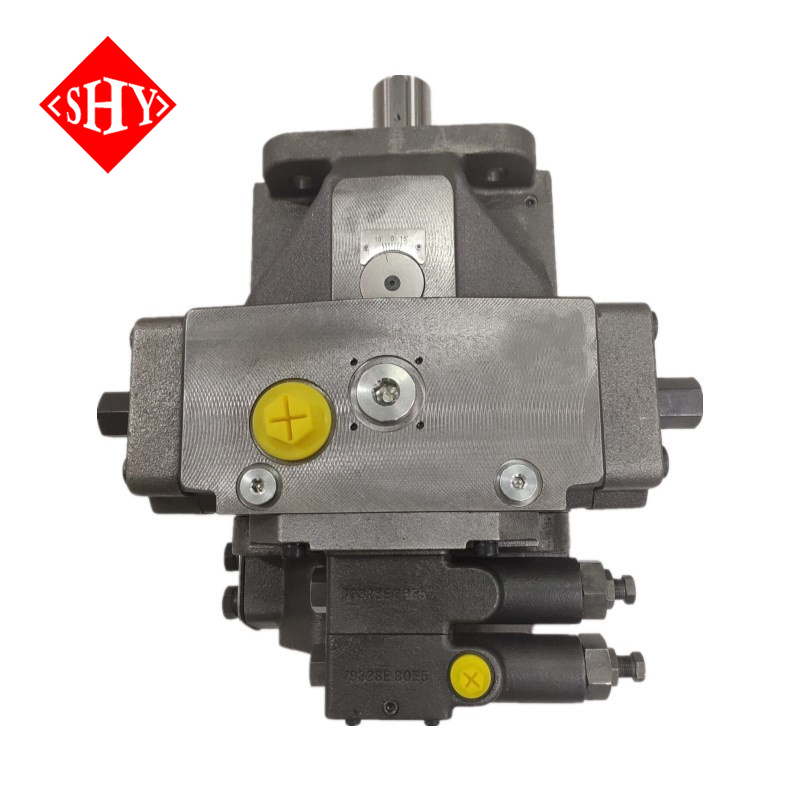

Product Overview

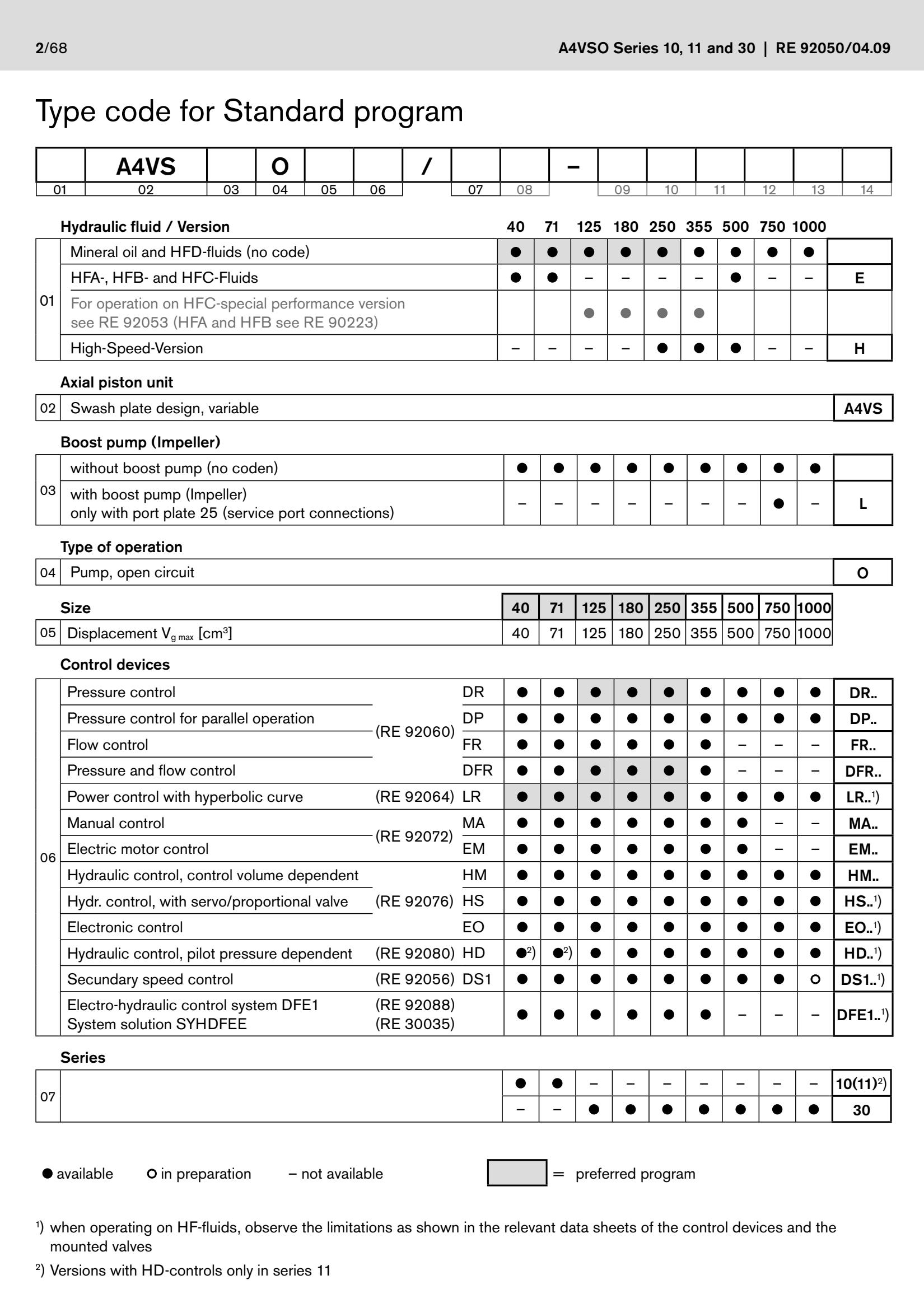

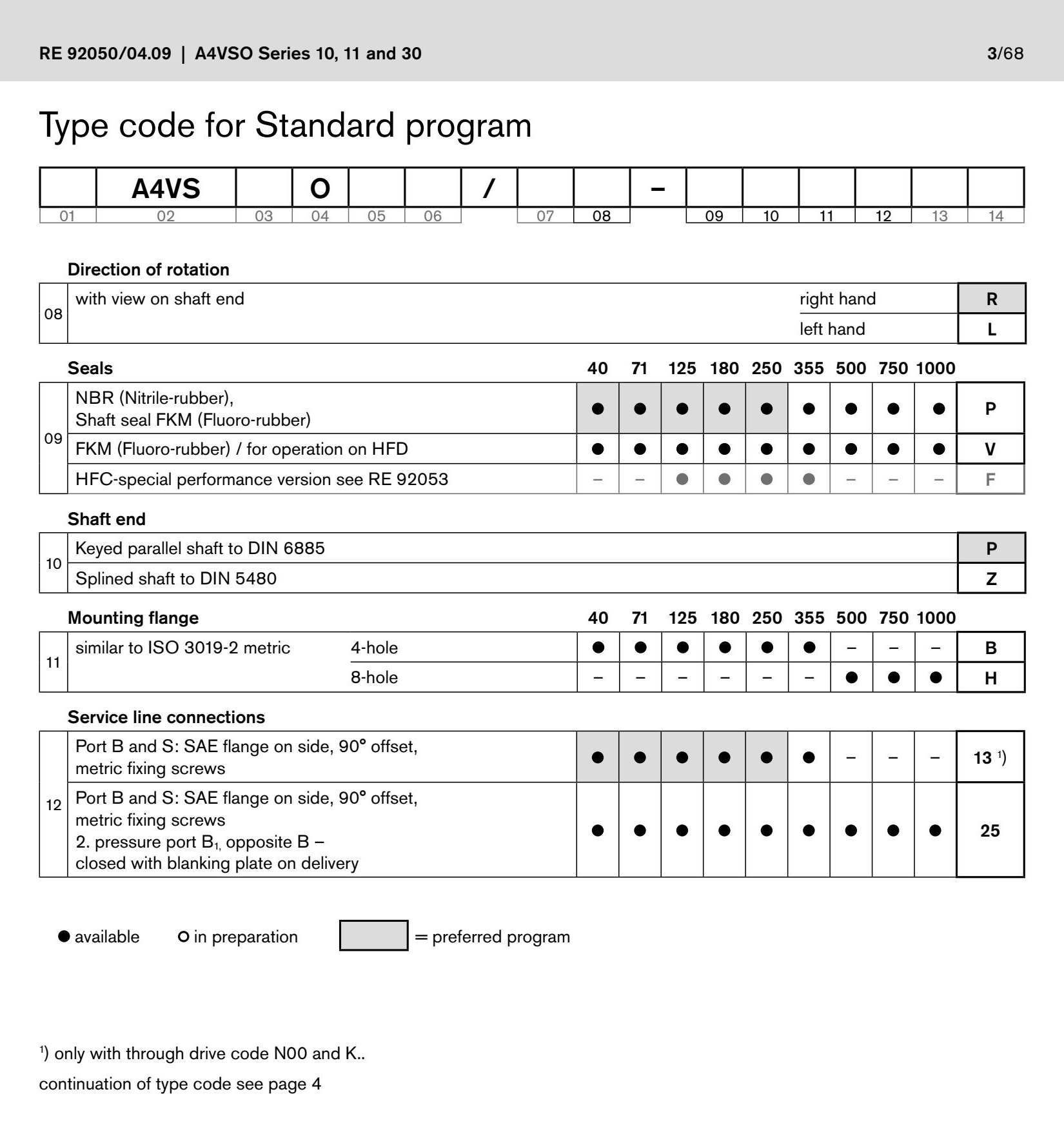

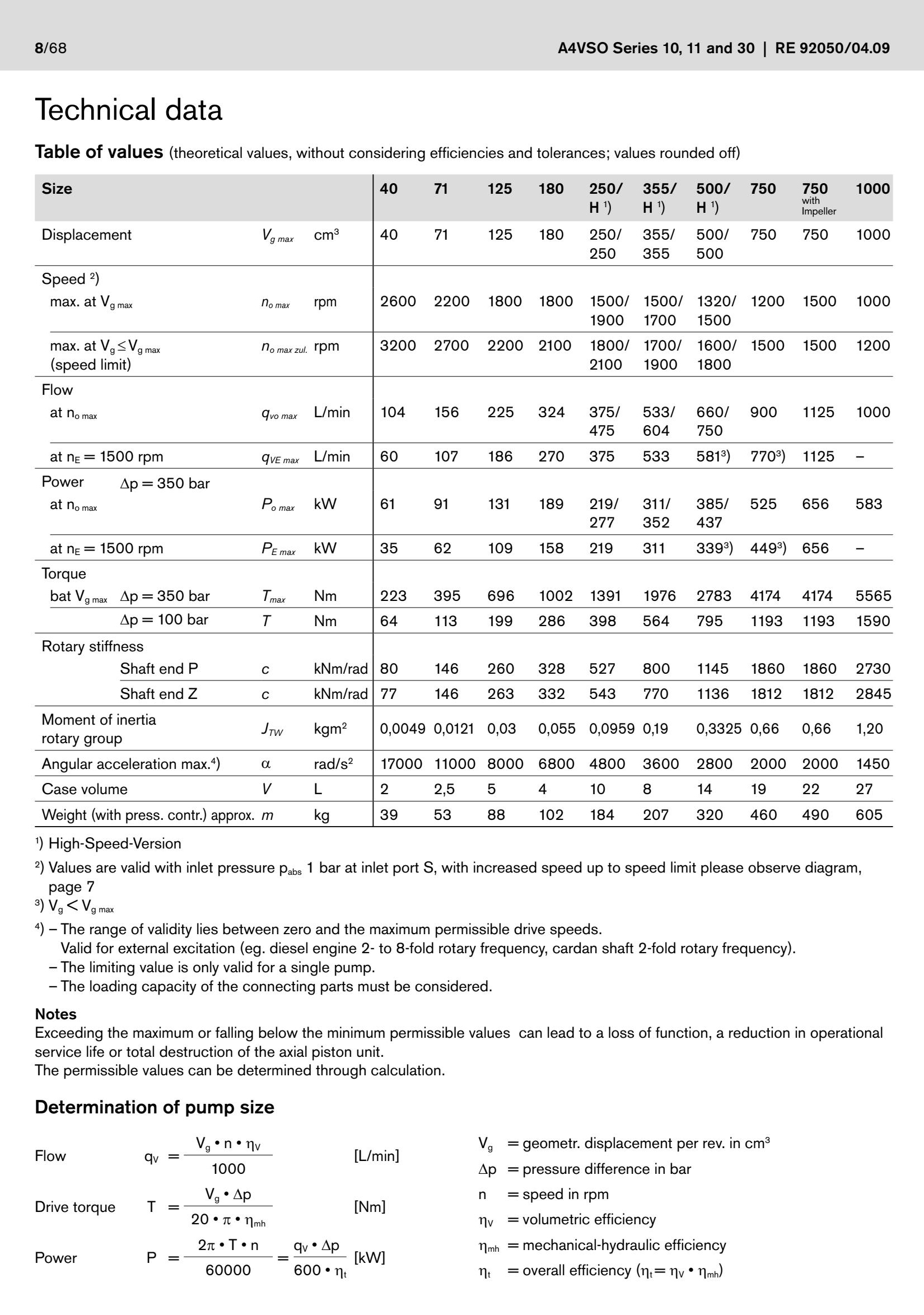

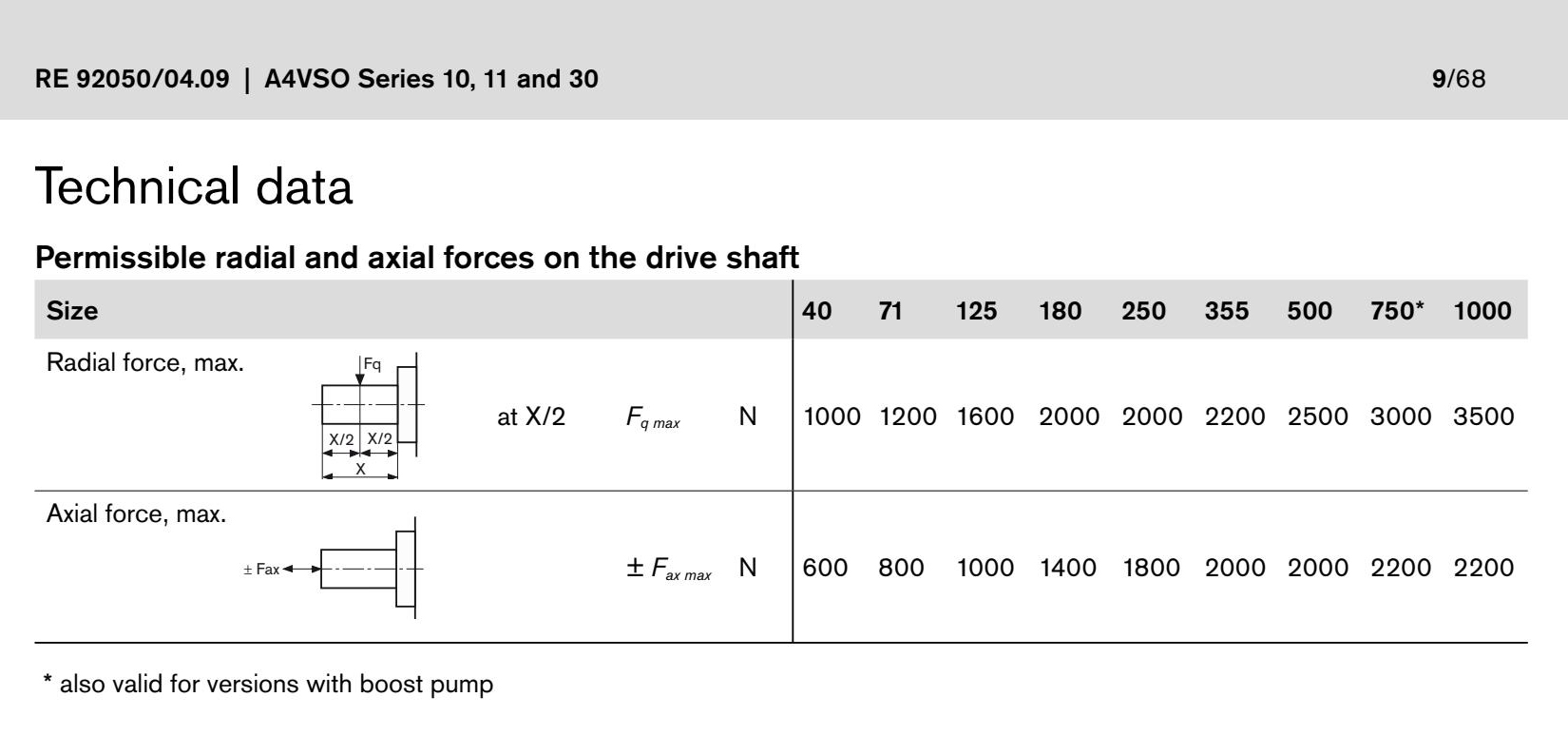

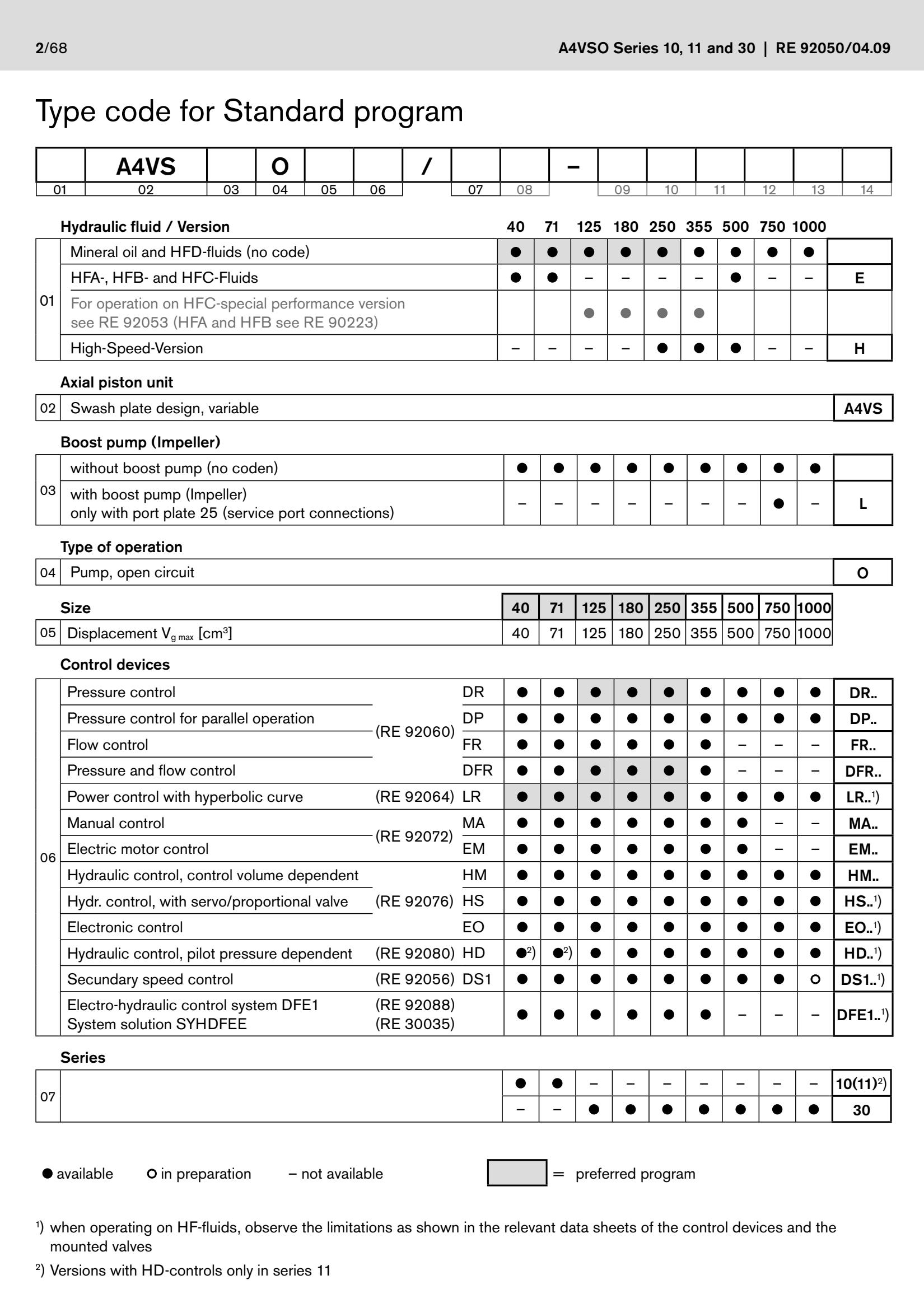

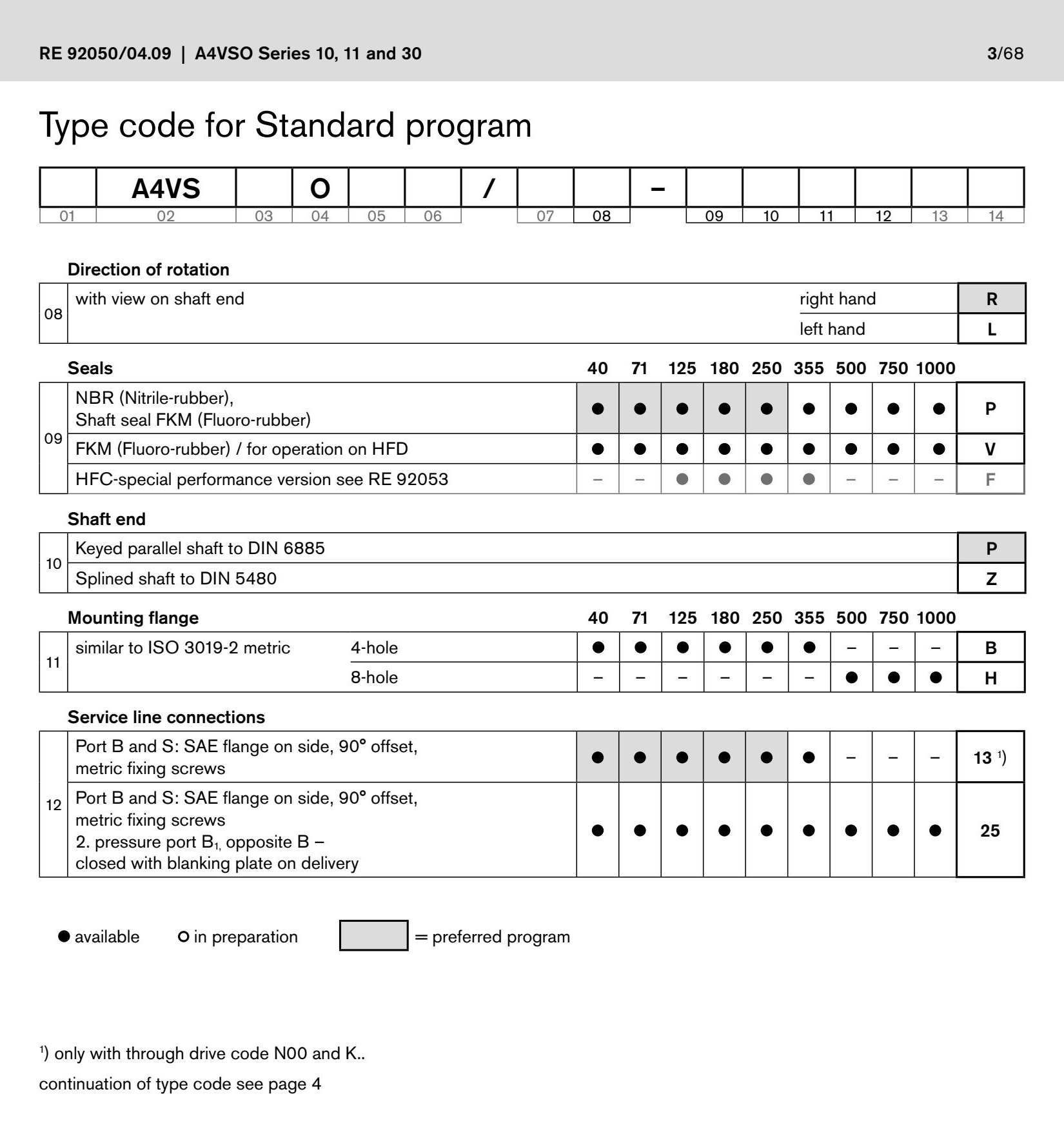

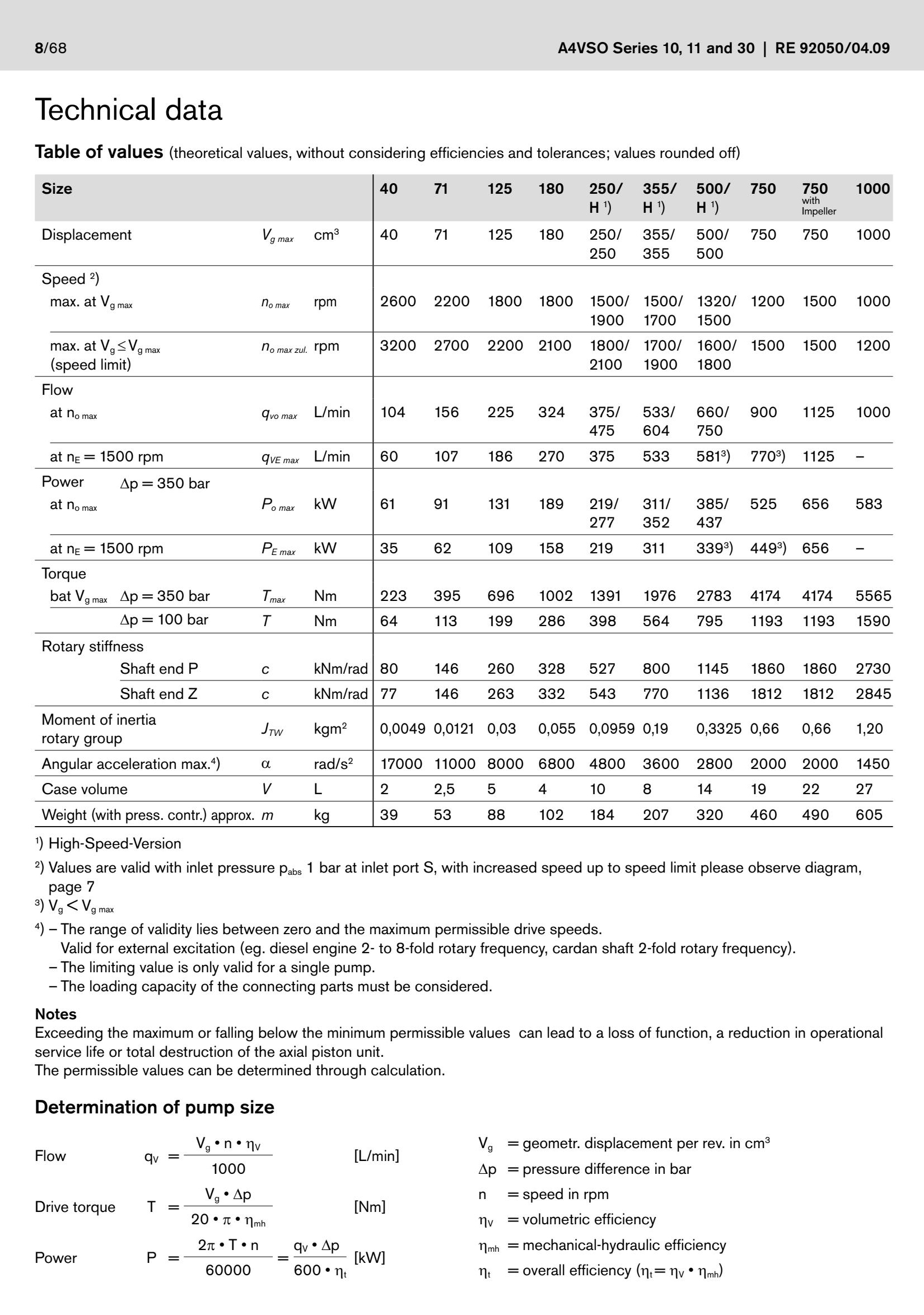

The A4VSO40-355 Hydraulic Piston Pump represents a premium solution for concrete machinery, engineered to withstand the high-pressure demands of concrete pumping and mixing applications. As a variable displacement axial piston pump, it features a modular design optimized for open-circuit systems in heavy-duty construction equipment. With a nominal operating pressure of 350 bar (5,076 psi) and peak pressure tolerance up to 400 bar (5,801 psi), this pump series delivers the high flow rates required for concrete pump boom extensions and material conveying . Covering a broad displacement range from 40 cc to 355 cc, it accommodates various machine sizes from small mobile mixers to large stationary concrete pumps. The pump’s DR pressure control system allows stepless pressure setting between 20-350 bar, ensuring precise matching to concrete viscosity and pumping distance requirements.

Product Features

• Wide Displacement Range: Available in 40 cc, 71 cc, 125 cc, 180 cc, 250 cc, 300 cc, and 355 cc variants to match specific concrete machinery needs—from 30m boom pumps (125 cc) to 60m+ large-scale concrete pumps (355 cc) .

• Fluid Versatility: Certified for use with mineral oils (ISO VG 46-68) and selected HFC fire-resistant fluids, making it suitable for indoor construction sites and tunnels where fire safety is critical .

• Durable Construction: Forged steel cylinder block and hardened alloy pistons (HRC 58-60) resist wear from abrasive concrete fines in hydraulic fluid, extending service life to over 10,000 operating hours in typical concrete pump applications .

• Efficient Operation: Achieves 94% volumetric efficiency at rated pressure, minimizing heat generation and reducing the load on cooling systems—essential for continuous operation in hot asphalt mixing plants .

Applications

Ideal for concrete pump trucks (supporting boom extension/retraction and concrete cylinder actuation), this pump ensures steady material flow for high-rise construction and bridge projects. It powers stationary concrete pumps used in precast concrete factories, enabling precise control of concrete placement in molds. In concrete mixing trucks, the A4VSO40-355 regulates drum rotation speed to maintain concrete consistency during transport. It also finds application in shotcrete machines for tunnel lining and slope stabilization, where reliable high-pressure performance is critical for material adhesion. Additionally, the pump supports concrete batching plant equipment such as aggregate conveyors and mixer discharge gates, ensuring synchronized operation of complex concrete production lines. Its ability to handle high pressures and variable loads makes it indispensable in modern concrete construction, where productivity and reliability directly impact project timelines.

Product Overview

The A4VSO40-355 Hydraulic Piston Pump represents a premium solution for concrete machinery, engineered to withstand the high-pressure demands of concrete pumping and mixing applications. As a variable displacement axial piston pump, it features a modular design optimized for open-circuit systems in heavy-duty construction equipment. With a nominal operating pressure of 350 bar (5,076 psi) and peak pressure tolerance up to 400 bar (5,801 psi), this pump series delivers the high flow rates required for concrete pump boom extensions and material conveying . Covering a broad displacement range from 40 cc to 355 cc, it accommodates various machine sizes from small mobile mixers to large stationary concrete pumps. The pump’s DR pressure control system allows stepless pressure setting between 20-350 bar, ensuring precise matching to concrete viscosity and pumping distance requirements.

Product Features

• Wide Displacement Range: Available in 40 cc, 71 cc, 125 cc, 180 cc, 250 cc, 300 cc, and 355 cc variants to match specific concrete machinery needs—from 30m boom pumps (125 cc) to 60m+ large-scale concrete pumps (355 cc) .

• Fluid Versatility: Certified for use with mineral oils (ISO VG 46-68) and selected HFC fire-resistant fluids, making it suitable for indoor construction sites and tunnels where fire safety is critical .

• Durable Construction: Forged steel cylinder block and hardened alloy pistons (HRC 58-60) resist wear from abrasive concrete fines in hydraulic fluid, extending service life to over 10,000 operating hours in typical concrete pump applications .

• Efficient Operation: Achieves 94% volumetric efficiency at rated pressure, minimizing heat generation and reducing the load on cooling systems—essential for continuous operation in hot asphalt mixing plants .

Applications

Ideal for concrete pump trucks (supporting boom extension/retraction and concrete cylinder actuation), this pump ensures steady material flow for high-rise construction and bridge projects. It powers stationary concrete pumps used in precast concrete factories, enabling precise control of concrete placement in molds. In concrete mixing trucks, the A4VSO40-355 regulates drum rotation speed to maintain concrete consistency during transport. It also finds application in shotcrete machines for tunnel lining and slope stabilization, where reliable high-pressure performance is critical for material adhesion. Additionally, the pump supports concrete batching plant equipment such as aggregate conveyors and mixer discharge gates, ensuring synchronized operation of complex concrete production lines. Its ability to handle high pressures and variable loads makes it indispensable in modern concrete construction, where productivity and reliability directly impact project timelines.