| Availability: | |

|---|---|

| Quantity: | |

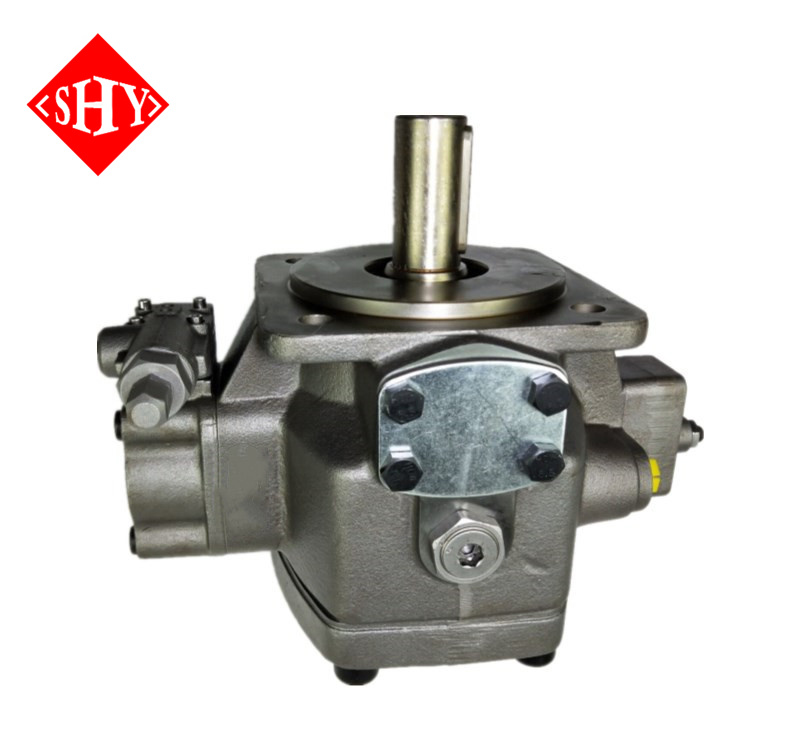

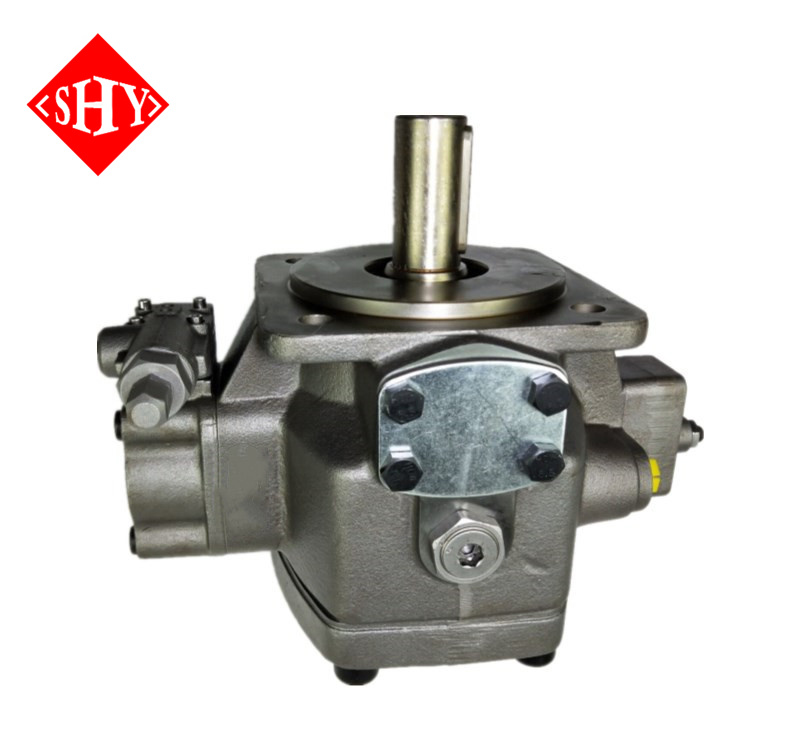

Product Overview

The PV7 Direct Control Variable Vane Pump stands as a high-efficiency solution for hydraulic systems requiring precise flow regulation, fully compliant with Rexroth’s strict quality standards (DIN EN ISO 9001:2015). This vane pump integrates a compact, space-saving design (with a maximum height of 280mm for FS 100 models) with versatile performance, covering light to medium-duty industrial applications. Its direct control mechanism—powered by a spring-loaded pressure compensator—enables real-time flow adjustment (from 0% to 100% of nominal flow) without relying on complex auxiliary valves or electronic controllers, making it ideal for systems where operational flexibility and energy efficiency are critical. Compatible with mineral-based oils (ISO VG 32-68), synthetic hydraulic fluids (e.g., polyalphaolefins), and even fire-resistant HFC fluids (for high-temperature environments), it seamlessly integrates into existing setups across automotive, packaging, and general machinery sectors. Additionally, it operates stably in ambient temperatures ranging from -10°C to 60°C, adapting to most workshop conditions.

Product Features

Broad Displacement Range: Available in 14 cc to 150 cc displacements (spanning FS 10, FS 25, FS 45, FS 70, FS 100 frame sizes) to deliver flow rates from 21 L/min to 218 L/min at 1800 rpm—sufficient for powering small clamping cylinders (21 L/min) to large conveyor drives (218 L/min), accommodating diverse system demands .

High Operating Pressure: Sustains a maximum working pressure of 160 bar (2,320 psi) with a pressure drop of less than 5 bar at full flow, ensuring stable performance in medium-pressure applications like plastic injection molding ejectors and textile roll tensioners .

Energy-Efficient Design: Achieves up to 92% volumetric efficiency through optimized vane geometry (curved vane profiles reduce fluid turbulence) and precision machining (cylinder bore tolerance of ±0.005mm), reducing energy consumption by up to 15% compared to conventional vane pumps (e.g., older PV2 series). This translates to annual electricity savings of approximately 2,200 kWh for a 24/7 operating packaging line .

Compact & Lightweight: Weighs only 12.5 kg to 56 kg (depending on frame size)—30% lighter than cast-iron vane pumps of similar capacity—with a space-saving footprint (FS 10 model: 180mm × 120mm × 150mm), simplifying installation in confined machinery layouts (e.g., automated guided vehicle (AGV) hydraulic systems) .

Applications

Widely utilized in automotive assembly lines (hydraulic clamping systems for engine block machining, brake booster test stands), packaging machinery (film winding drives for stretch wrap machines, labeler pressure rollers), plastic injection molding (ejector systems for small-component molding, mold temperature control circuits), and textile equipment (roll tension control for weaving machines, yarn winding hydraulic drives). Its direct flow control capability (response time < 0.8 seconds) makes it particularly suitable for applications requiring rapid pressure adjustments, such as automated material handling systems (palletizer lift cylinders) and precision press machines (10-ton stamping presses for electronic components).

Product Overview

The PV7 Direct Control Variable Vane Pump stands as a high-efficiency solution for hydraulic systems requiring precise flow regulation, fully compliant with Rexroth’s strict quality standards (DIN EN ISO 9001:2015). This vane pump integrates a compact, space-saving design (with a maximum height of 280mm for FS 100 models) with versatile performance, covering light to medium-duty industrial applications. Its direct control mechanism—powered by a spring-loaded pressure compensator—enables real-time flow adjustment (from 0% to 100% of nominal flow) without relying on complex auxiliary valves or electronic controllers, making it ideal for systems where operational flexibility and energy efficiency are critical. Compatible with mineral-based oils (ISO VG 32-68), synthetic hydraulic fluids (e.g., polyalphaolefins), and even fire-resistant HFC fluids (for high-temperature environments), it seamlessly integrates into existing setups across automotive, packaging, and general machinery sectors. Additionally, it operates stably in ambient temperatures ranging from -10°C to 60°C, adapting to most workshop conditions.

Product Features

Broad Displacement Range: Available in 14 cc to 150 cc displacements (spanning FS 10, FS 25, FS 45, FS 70, FS 100 frame sizes) to deliver flow rates from 21 L/min to 218 L/min at 1800 rpm—sufficient for powering small clamping cylinders (21 L/min) to large conveyor drives (218 L/min), accommodating diverse system demands .

High Operating Pressure: Sustains a maximum working pressure of 160 bar (2,320 psi) with a pressure drop of less than 5 bar at full flow, ensuring stable performance in medium-pressure applications like plastic injection molding ejectors and textile roll tensioners .

Energy-Efficient Design: Achieves up to 92% volumetric efficiency through optimized vane geometry (curved vane profiles reduce fluid turbulence) and precision machining (cylinder bore tolerance of ±0.005mm), reducing energy consumption by up to 15% compared to conventional vane pumps (e.g., older PV2 series). This translates to annual electricity savings of approximately 2,200 kWh for a 24/7 operating packaging line .

Compact & Lightweight: Weighs only 12.5 kg to 56 kg (depending on frame size)—30% lighter than cast-iron vane pumps of similar capacity—with a space-saving footprint (FS 10 model: 180mm × 120mm × 150mm), simplifying installation in confined machinery layouts (e.g., automated guided vehicle (AGV) hydraulic systems) .

Applications

Widely utilized in automotive assembly lines (hydraulic clamping systems for engine block machining, brake booster test stands), packaging machinery (film winding drives for stretch wrap machines, labeler pressure rollers), plastic injection molding (ejector systems for small-component molding, mold temperature control circuits), and textile equipment (roll tension control for weaving machines, yarn winding hydraulic drives). Its direct flow control capability (response time < 0.8 seconds) makes it particularly suitable for applications requiring rapid pressure adjustments, such as automated material handling systems (palletizer lift cylinders) and precision press machines (10-ton stamping presses for electronic components).