| Availability: | |

|---|---|

| Quantity: | |

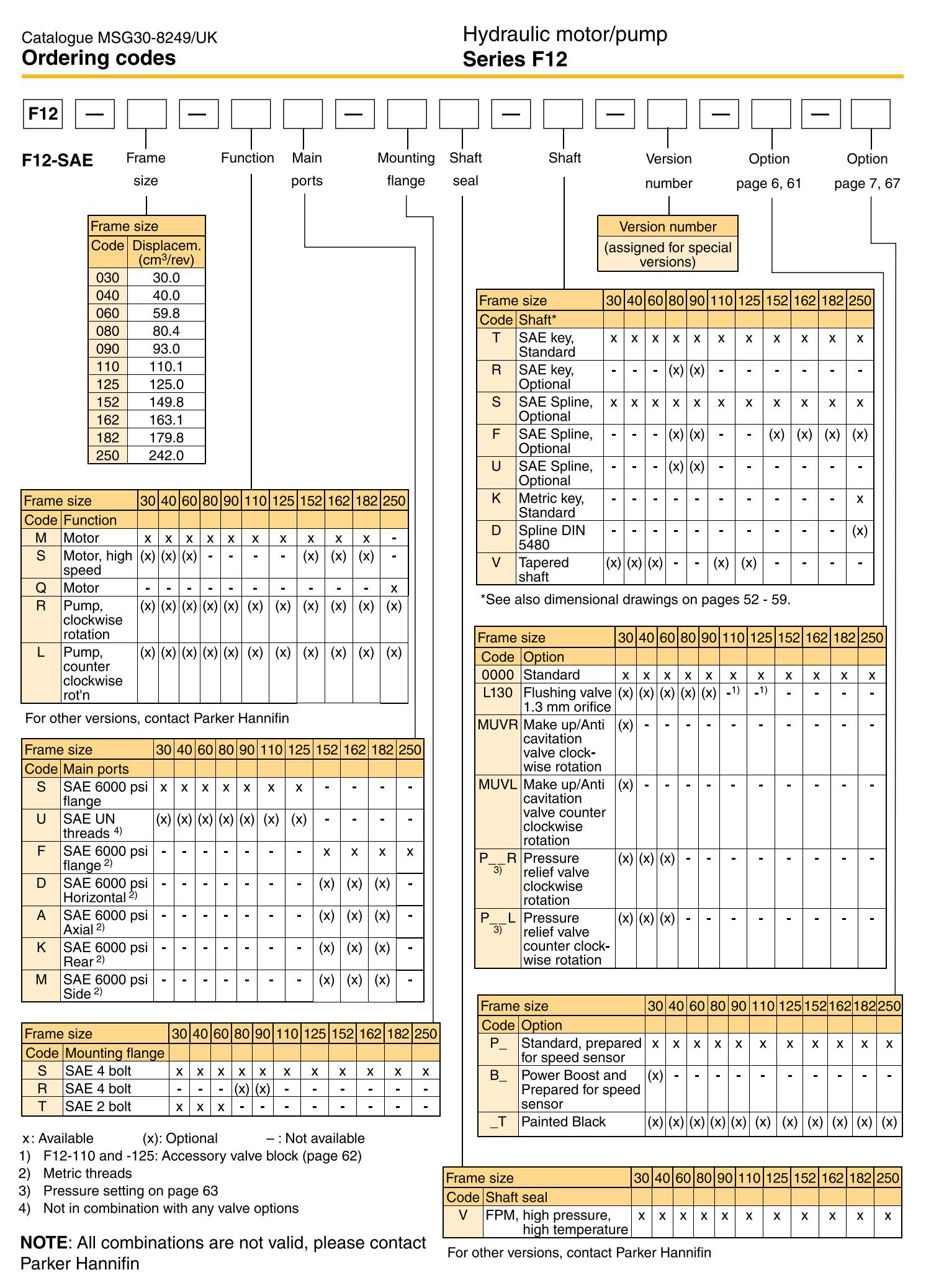

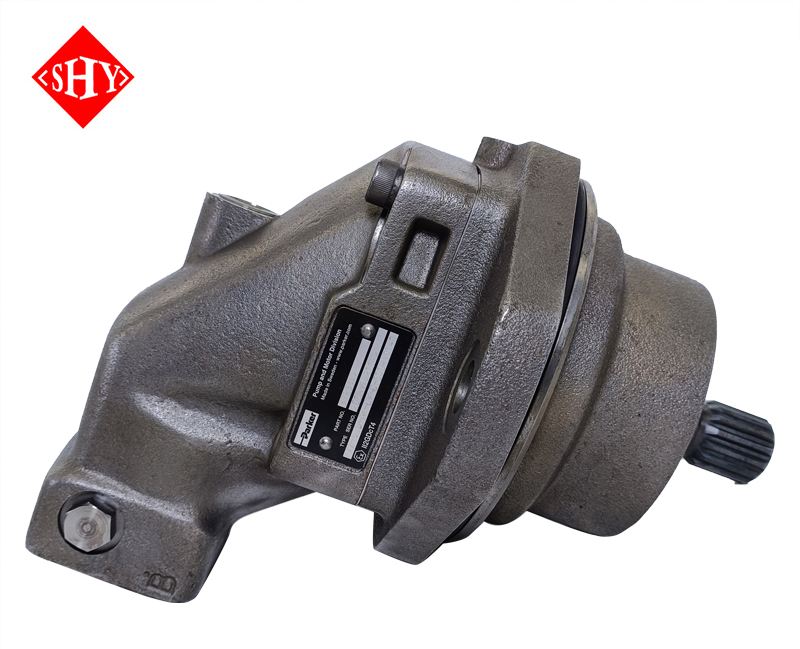

Product Overview

The F12 Fixed Displacement Hydraulic Piston Motor is engineered for heavy-duty hydraulic circuits, delivering high torque and stability in demanding industrial environments (e.g., mining, offshore operations). Its robust design includes a reinforced housing (cast ductile iron, EN-GJS-400-15) that resists impact and corrosion, supporting extended operation in harsh conditions (e.g., saltwater spray, coal dust). The motor also features a built-in drain port to remove residual fluid, preventing internal corrosion during long-term storage or idle periods.

Product Features

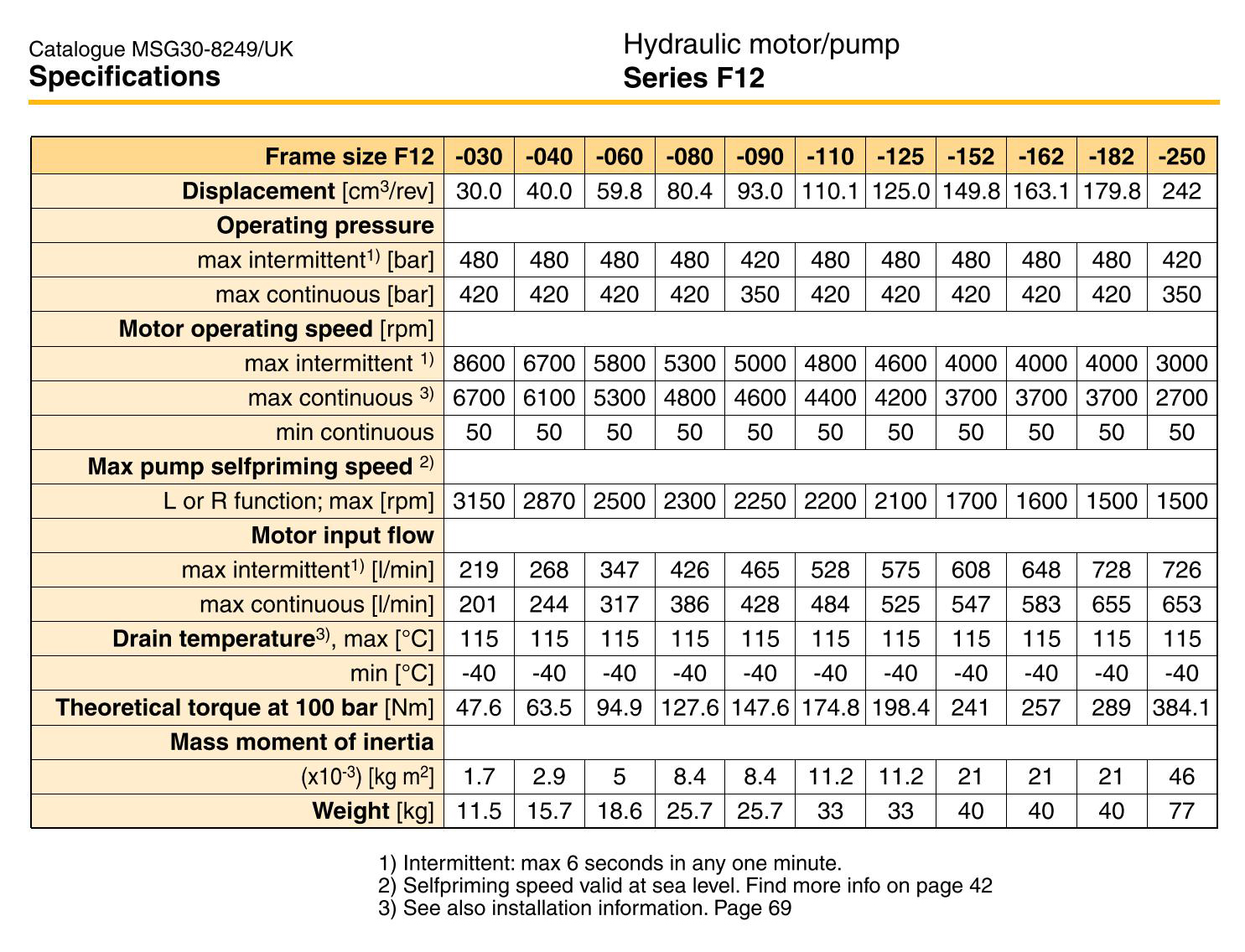

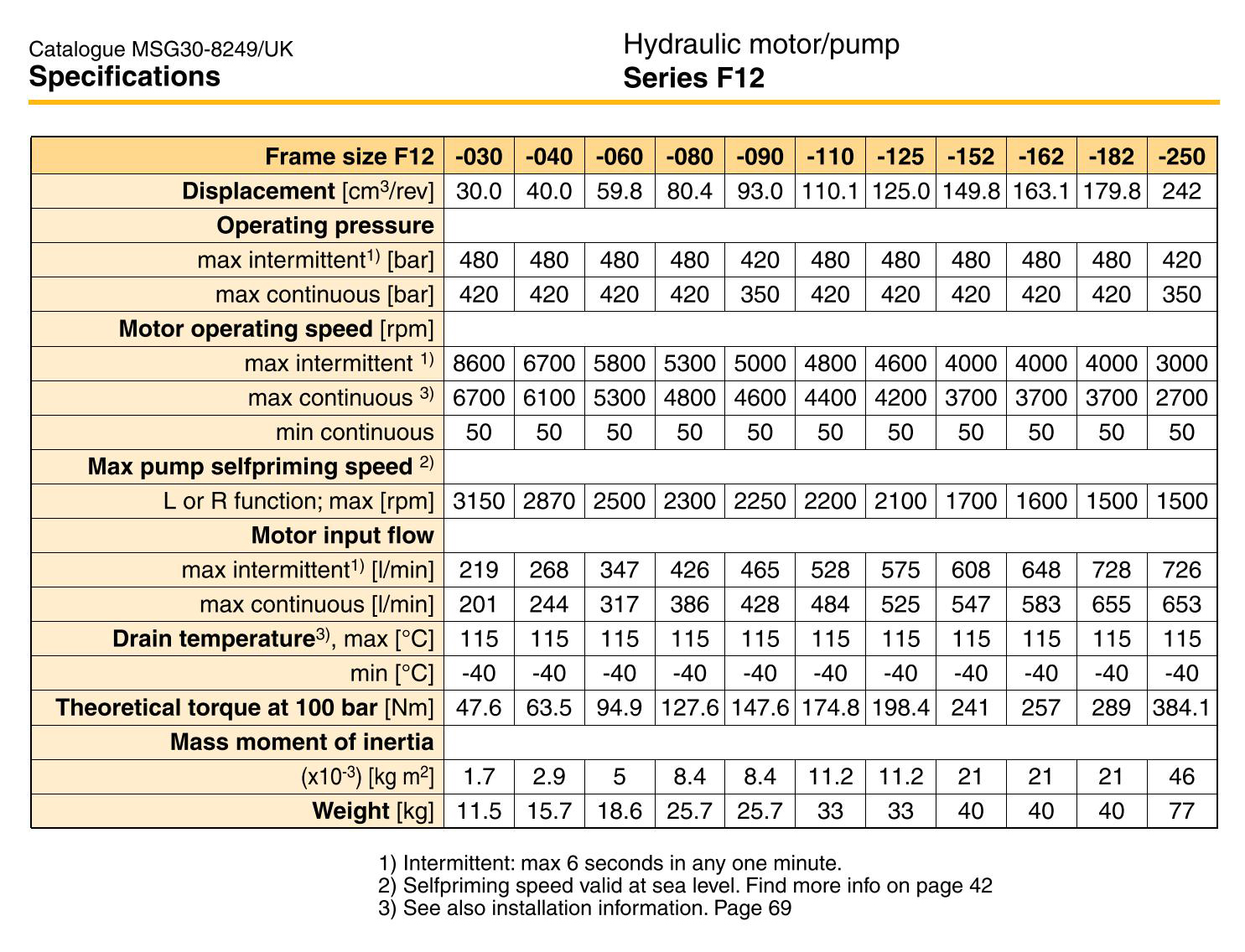

High Pressure Rating: Operates continuously at 420 bar (6,100 psi) with intermittent peaks up to 480 bar (7,250 psi). At rated pressure, its output torque reaches 1,200 N·m—sufficient to drive heavy equipment like 100-ton mining dump truck wheel hubs or large offshore drilling rig winches.

Smooth Torque Output: A 7 or 9 piston design (depending on displacement) with staggered piston arrangement reduces flow pulsation to less than 5%. This minimizes vibration in the hydraulic circuit, extending the life of downstream components (e.g., hoses, valves) by 30% and reducing maintenance costs.

Heavy-Duty Bearings: Equipped with double-row angular contact ball bearings (SKF 3206A) that accommodate substantial axial loads (up to 50 kN) and radial loads (up to 35 kN). This makes the motor suitable for rugged machinery with multi-directional loads, such as port container crane hoists or large-scale conveyor system drives.

Applications

Ideal for industrial presses (2,000-ton metal forging presses), mining equipment (coal crusher hydraulic drives), offshore drilling rigs (drill string rotation systems), and large-scale conveyor systems (bulk material transport in power plants). Its ability to thrive in closed-loop circuits (e.g., variable-speed drives for heavy machinery) makes it a top choice for high-power hydraulic systems—for example, in offshore oil platforms, it can operate continuously in saltwater environments for over 5,000 hours with minimal maintenance.

Product Overview

The F12 Fixed Displacement Hydraulic Piston Motor is engineered for heavy-duty hydraulic circuits, delivering high torque and stability in demanding industrial environments (e.g., mining, offshore operations). Its robust design includes a reinforced housing (cast ductile iron, EN-GJS-400-15) that resists impact and corrosion, supporting extended operation in harsh conditions (e.g., saltwater spray, coal dust). The motor also features a built-in drain port to remove residual fluid, preventing internal corrosion during long-term storage or idle periods.

Product Features

High Pressure Rating: Operates continuously at 420 bar (6,100 psi) with intermittent peaks up to 480 bar (7,250 psi). At rated pressure, its output torque reaches 1,200 N·m—sufficient to drive heavy equipment like 100-ton mining dump truck wheel hubs or large offshore drilling rig winches.

Smooth Torque Output: A 7 or 9 piston design (depending on displacement) with staggered piston arrangement reduces flow pulsation to less than 5%. This minimizes vibration in the hydraulic circuit, extending the life of downstream components (e.g., hoses, valves) by 30% and reducing maintenance costs.

Heavy-Duty Bearings: Equipped with double-row angular contact ball bearings (SKF 3206A) that accommodate substantial axial loads (up to 50 kN) and radial loads (up to 35 kN). This makes the motor suitable for rugged machinery with multi-directional loads, such as port container crane hoists or large-scale conveyor system drives.

Applications

Ideal for industrial presses (2,000-ton metal forging presses), mining equipment (coal crusher hydraulic drives), offshore drilling rigs (drill string rotation systems), and large-scale conveyor systems (bulk material transport in power plants). Its ability to thrive in closed-loop circuits (e.g., variable-speed drives for heavy machinery) makes it a top choice for high-power hydraulic systems—for example, in offshore oil platforms, it can operate continuously in saltwater environments for over 5,000 hours with minimal maintenance.