| Availability: | |

|---|---|

| Quantity: | |

Product Overview

The Fixed Displacement F11 Hydraulic Piston Motor is a compact, high-speed motor designed for precision-driven hydraulic systems, featuring a bent-axis design (40° shaft-to-cylinder angle) that minimizes friction between pistons and the cylinder block. This design enhances mechanical efficiency (up to 96%) and ensures smooth power conversion in both open-loop (e.g., material handling conveyors) and closed-loop (e.g., robotic arms) circuits. It is compatible with a wide range of hydraulic fluids, including biodegradable oils (for eco-sensitive applications like forestry machinery) and high-viscosity oils (for low-temperature environments down to -20°C).

Product Features

High-Speed Capability: Reaches up to 14,000 rpm, with a dynamic balance grade of G2.5 (per ISO 1940)—this reduces vibration amplitude to less than 0.1 mm/s, preventing damage to precision components (e.g., sensor mounts, gearboxes) in rapid-cycle applications.

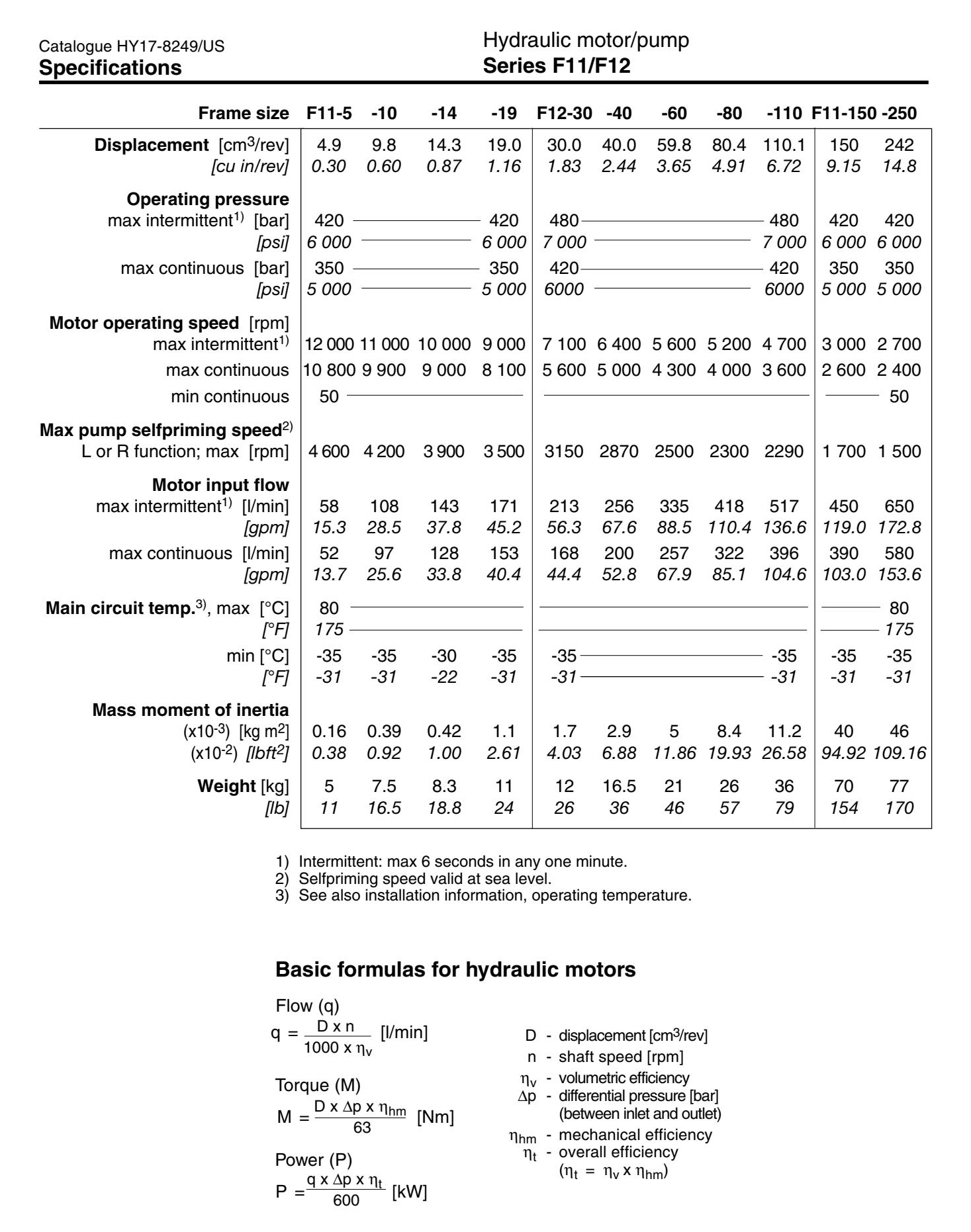

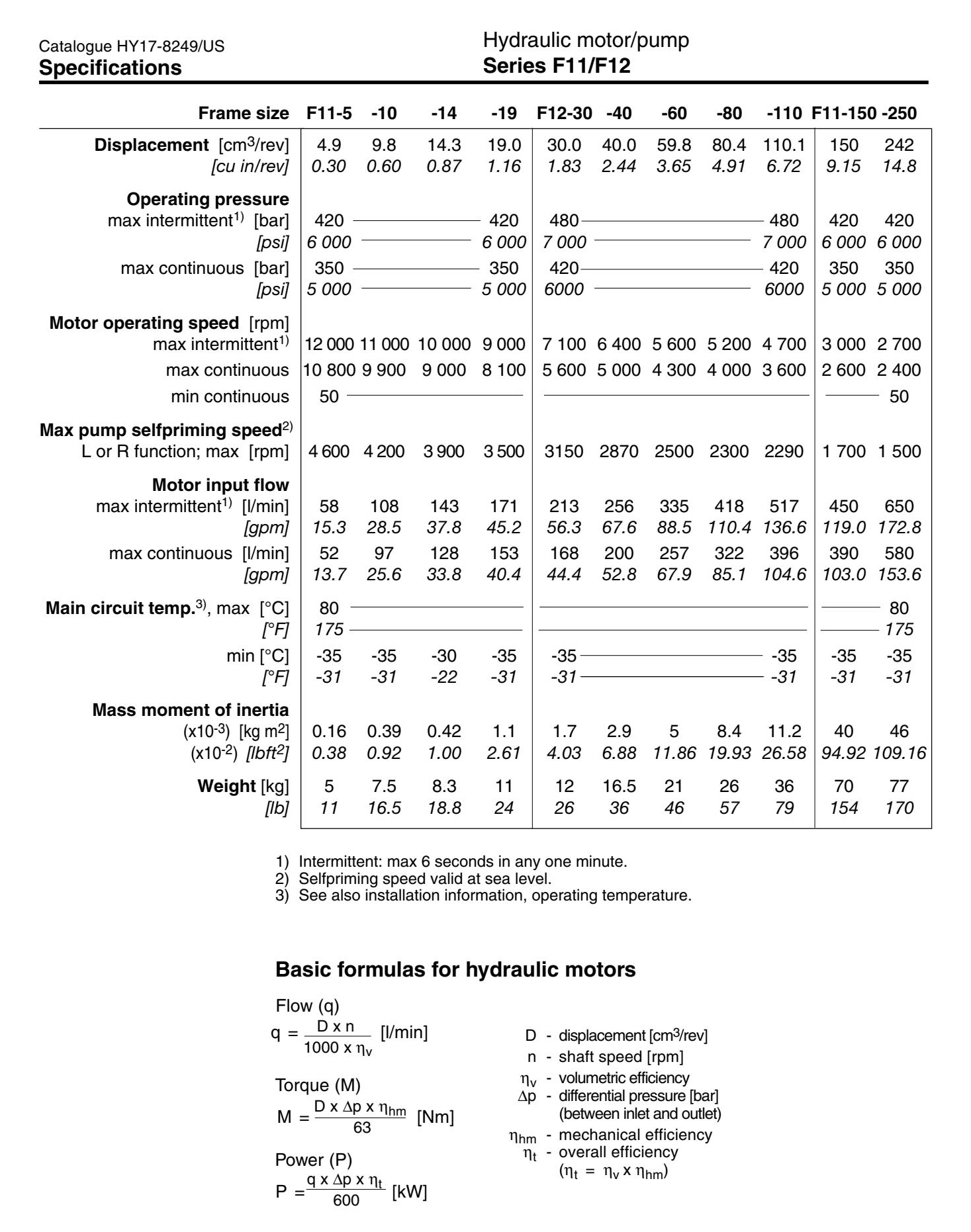

Pressure Resistance: Sustains continuous operating pressure of 350 bar (5,076 psi) and intermittent peaks up to 420 bar (6,100 psi). Its cylinder block is made of forged steel (SCM440), which has a tensile strength of 900 MPa—ensuring resistance to deformation under high pressure.

Compact Design: Small envelope size (e.g., 110 mm diameter × 150 mm length for the F11-050 model) with a power-to-weight ratio of 2.5 kW/kg—30% higher than conventional axial piston motors. This makes it suitable for installation in space-constrained equipment, such as robotic joints, small-scale automated guided vehicles (AGVs), and medical device actuators.

Durable Components: Laminated piston rings made of nickel-based alloy (Inconel 718) provide thermal shock resistance—they can withstand temperature changes from -20°C to 100°C without cracking. Additionally, the motor’s bearing assembly uses ceramic balls, which reduce friction by 25% compared to steel balls and extend bearing life to over 10,000 hours.

Applications

Used in precision machine tools (CNC lathe spindle drives), material handling systems (automated warehouse conveyor belt motors), and mobile equipment (small agricultural harvesters) requiring fast response and consistent torque output. It is particularly ideal for robotics (e.g., collaborative robot wrist joints) and automated production lines (e.g., electronic component placement machines), where its high speed and low vibration ensure precise motion control—positioning accuracy can be maintained within ±0.02 mm.

F11 Features

• Max intermittent pressure up to 420 bar and continuous operating pressure up to 350 bar

• Thanks to low weight pistons and a compact design of the rotating parts, the F11 tolerates very high speeds, up to 14000 rpm

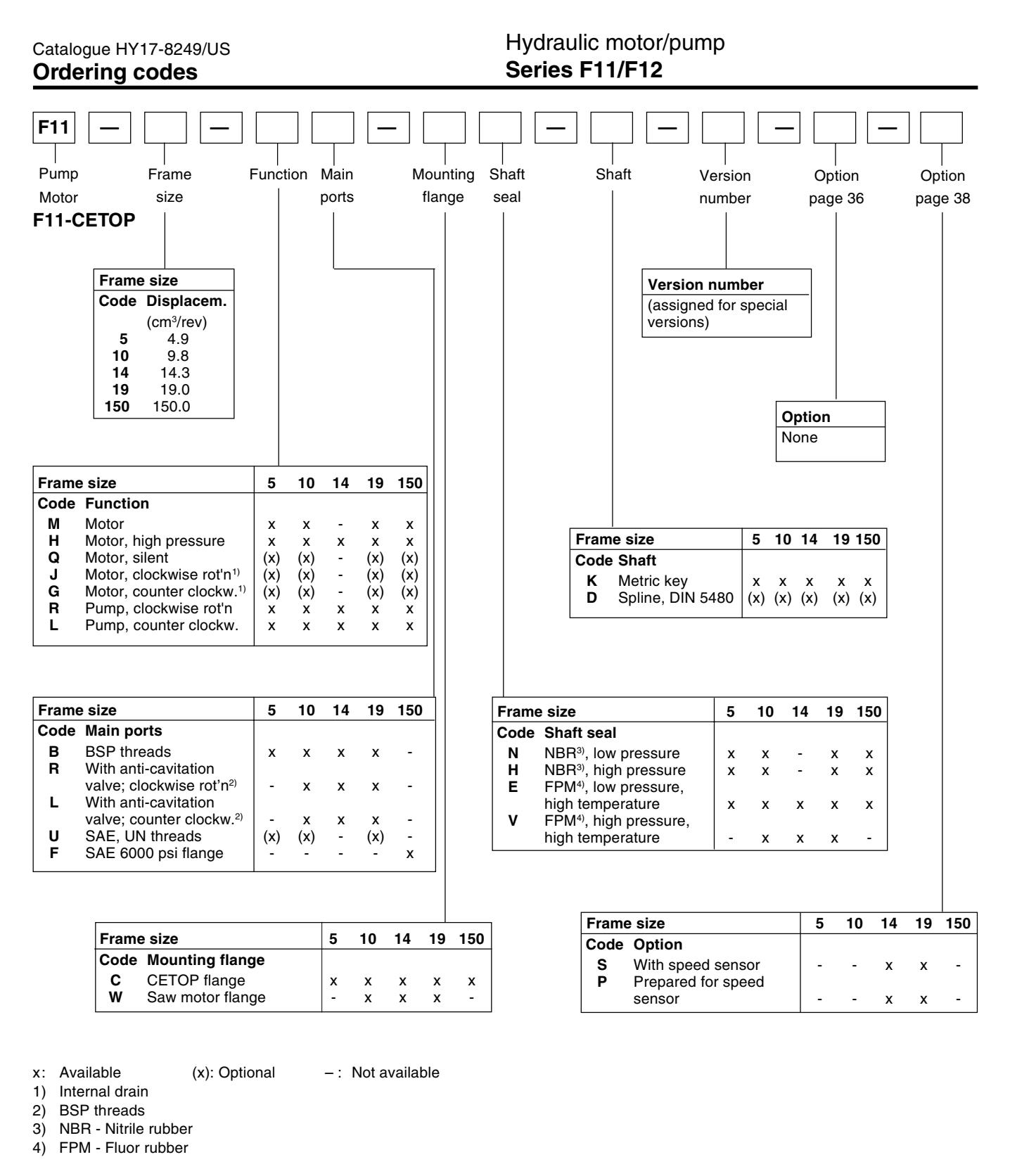

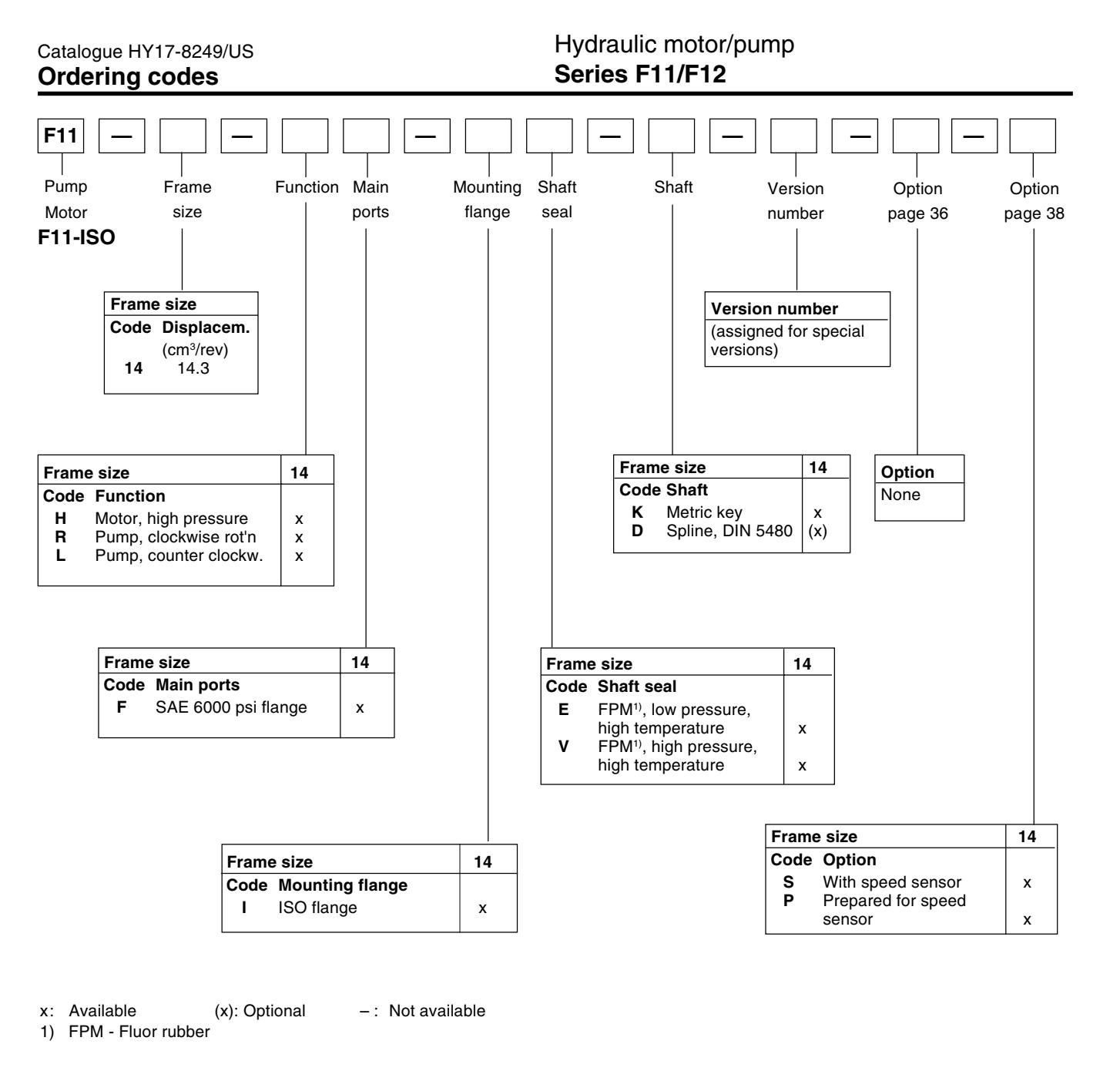

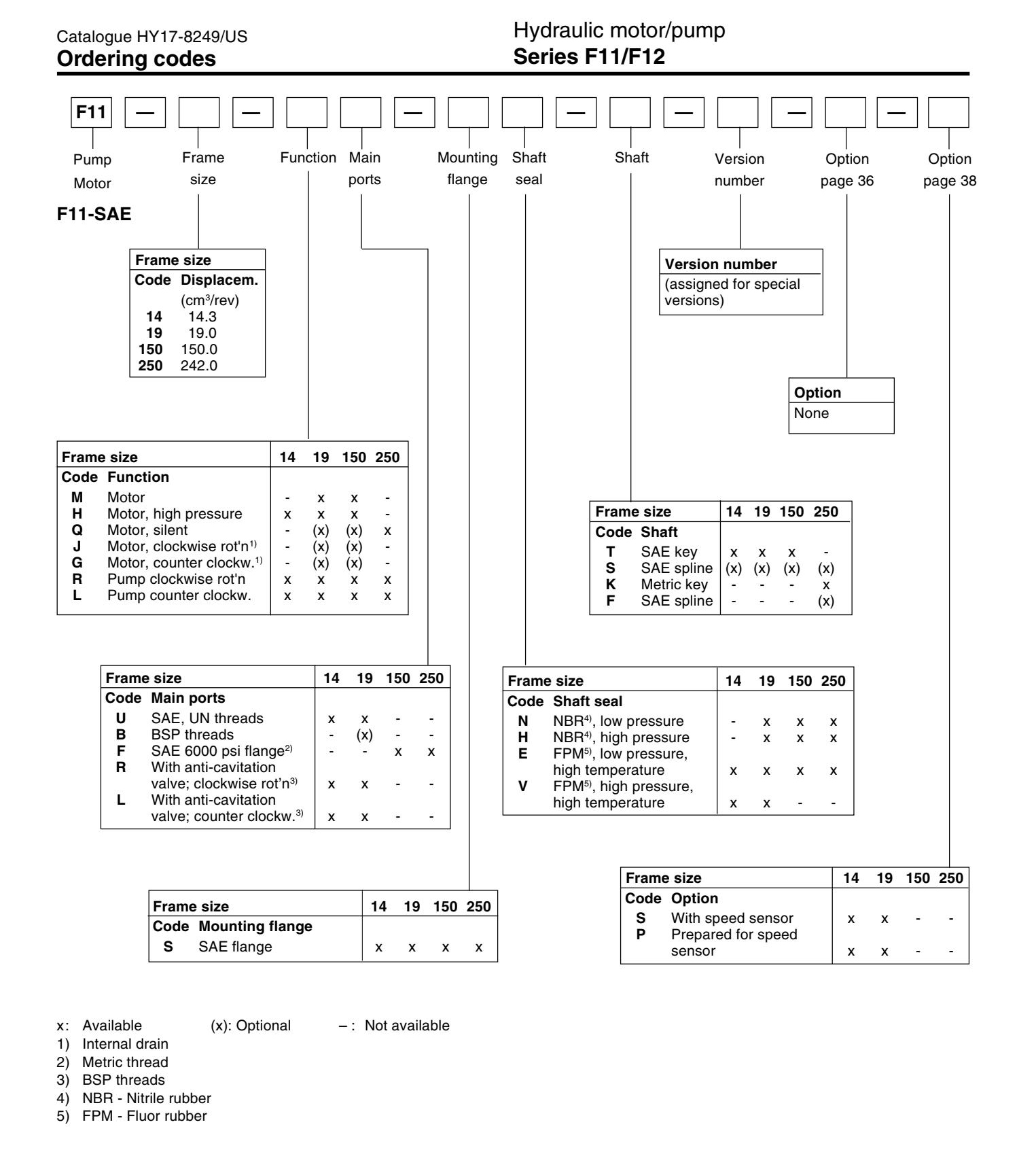

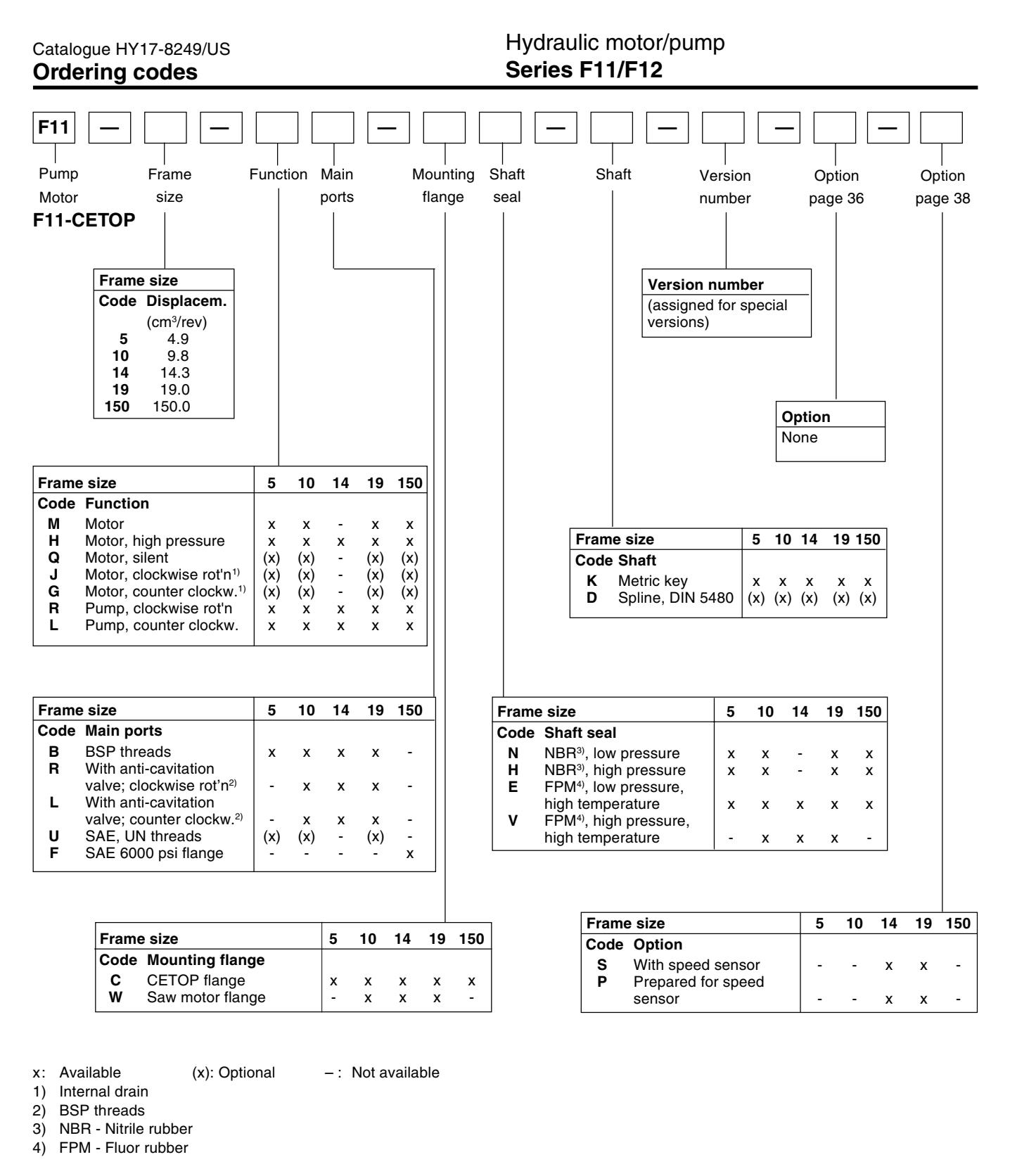

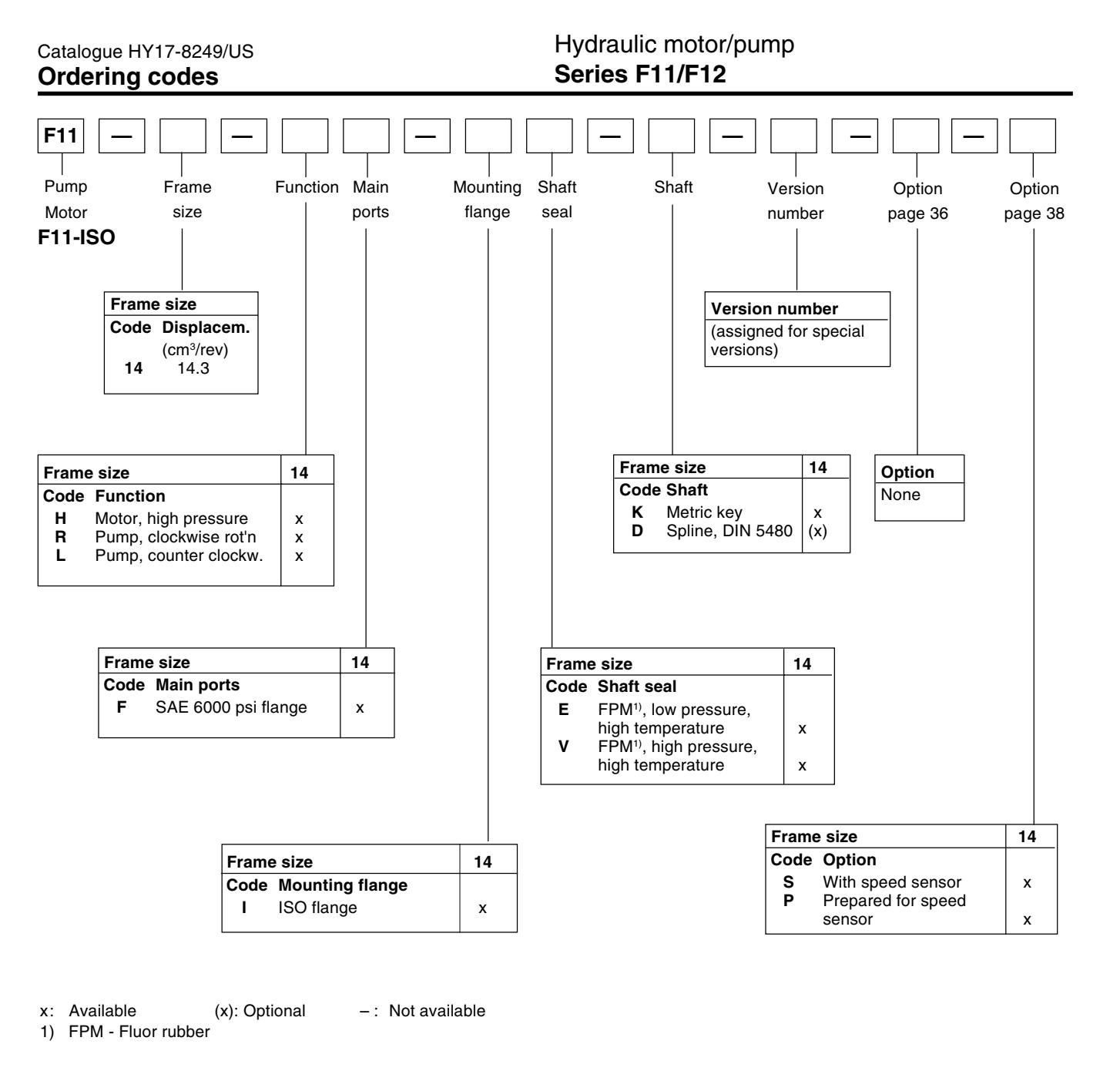

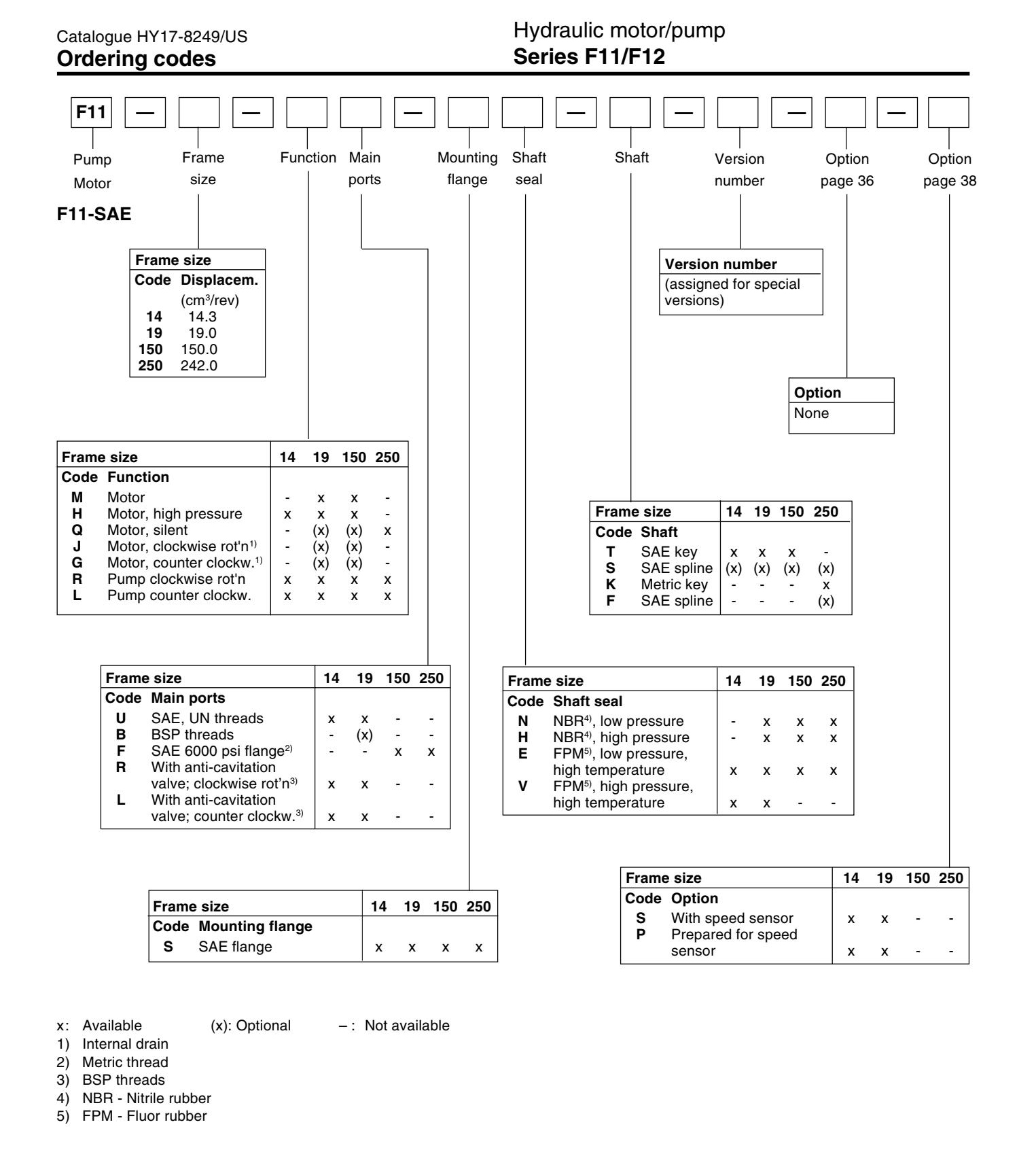

• CETOP, ISO, SAW and SAE versions

Product Overview

The Fixed Displacement F11 Hydraulic Piston Motor is a compact, high-speed motor designed for precision-driven hydraulic systems, featuring a bent-axis design (40° shaft-to-cylinder angle) that minimizes friction between pistons and the cylinder block. This design enhances mechanical efficiency (up to 96%) and ensures smooth power conversion in both open-loop (e.g., material handling conveyors) and closed-loop (e.g., robotic arms) circuits. It is compatible with a wide range of hydraulic fluids, including biodegradable oils (for eco-sensitive applications like forestry machinery) and high-viscosity oils (for low-temperature environments down to -20°C).

Product Features

High-Speed Capability: Reaches up to 14,000 rpm, with a dynamic balance grade of G2.5 (per ISO 1940)—this reduces vibration amplitude to less than 0.1 mm/s, preventing damage to precision components (e.g., sensor mounts, gearboxes) in rapid-cycle applications.

Pressure Resistance: Sustains continuous operating pressure of 350 bar (5,076 psi) and intermittent peaks up to 420 bar (6,100 psi). Its cylinder block is made of forged steel (SCM440), which has a tensile strength of 900 MPa—ensuring resistance to deformation under high pressure.

Compact Design: Small envelope size (e.g., 110 mm diameter × 150 mm length for the F11-050 model) with a power-to-weight ratio of 2.5 kW/kg—30% higher than conventional axial piston motors. This makes it suitable for installation in space-constrained equipment, such as robotic joints, small-scale automated guided vehicles (AGVs), and medical device actuators.

Durable Components: Laminated piston rings made of nickel-based alloy (Inconel 718) provide thermal shock resistance—they can withstand temperature changes from -20°C to 100°C without cracking. Additionally, the motor’s bearing assembly uses ceramic balls, which reduce friction by 25% compared to steel balls and extend bearing life to over 10,000 hours.

Applications

Used in precision machine tools (CNC lathe spindle drives), material handling systems (automated warehouse conveyor belt motors), and mobile equipment (small agricultural harvesters) requiring fast response and consistent torque output. It is particularly ideal for robotics (e.g., collaborative robot wrist joints) and automated production lines (e.g., electronic component placement machines), where its high speed and low vibration ensure precise motion control—positioning accuracy can be maintained within ±0.02 mm.

F11 Features

• Max intermittent pressure up to 420 bar and continuous operating pressure up to 350 bar

• Thanks to low weight pistons and a compact design of the rotating parts, the F11 tolerates very high speeds, up to 14000 rpm

• CETOP, ISO, SAW and SAE versions