| Availability: | |

|---|---|

| Quantity: | |

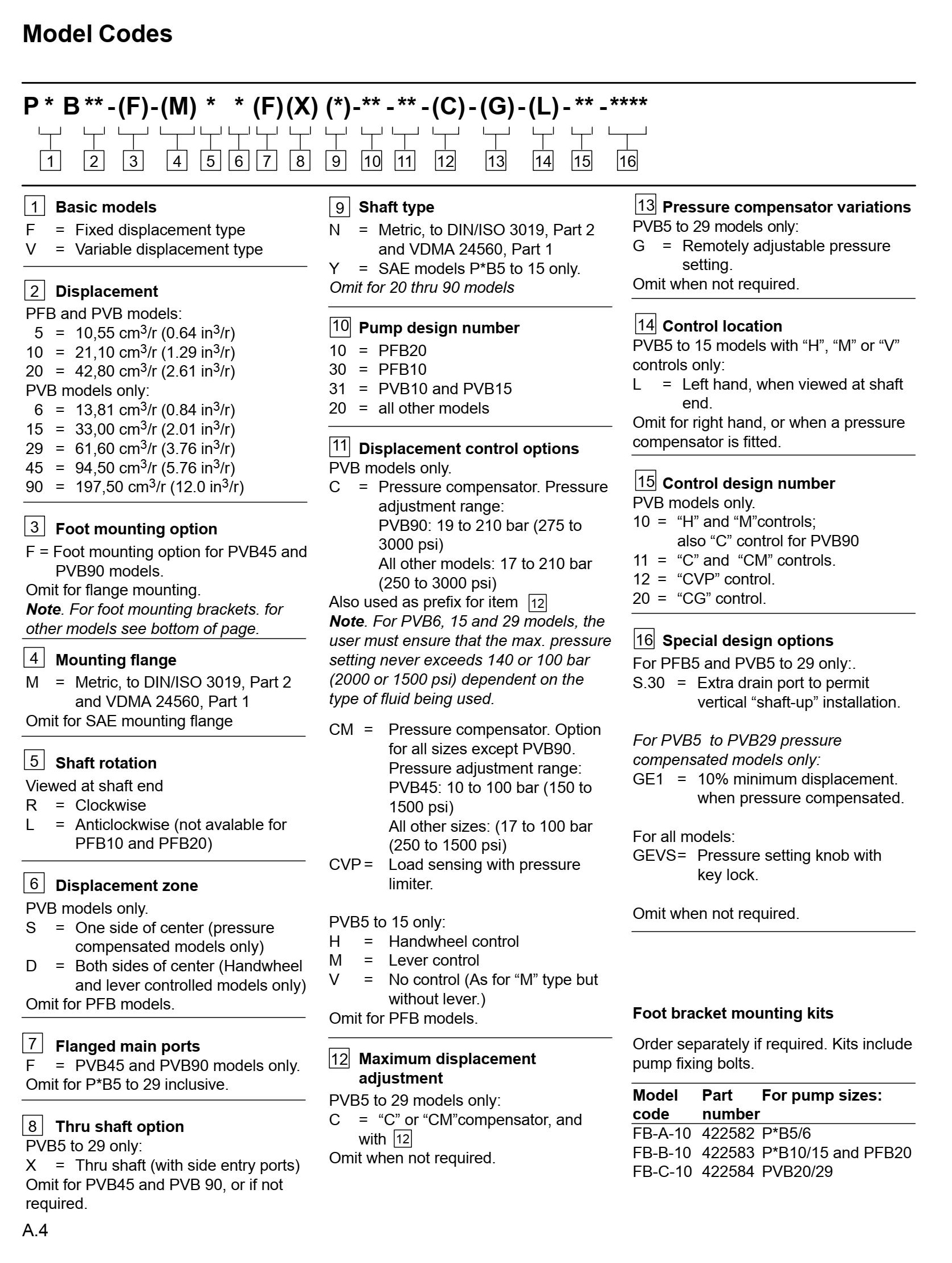

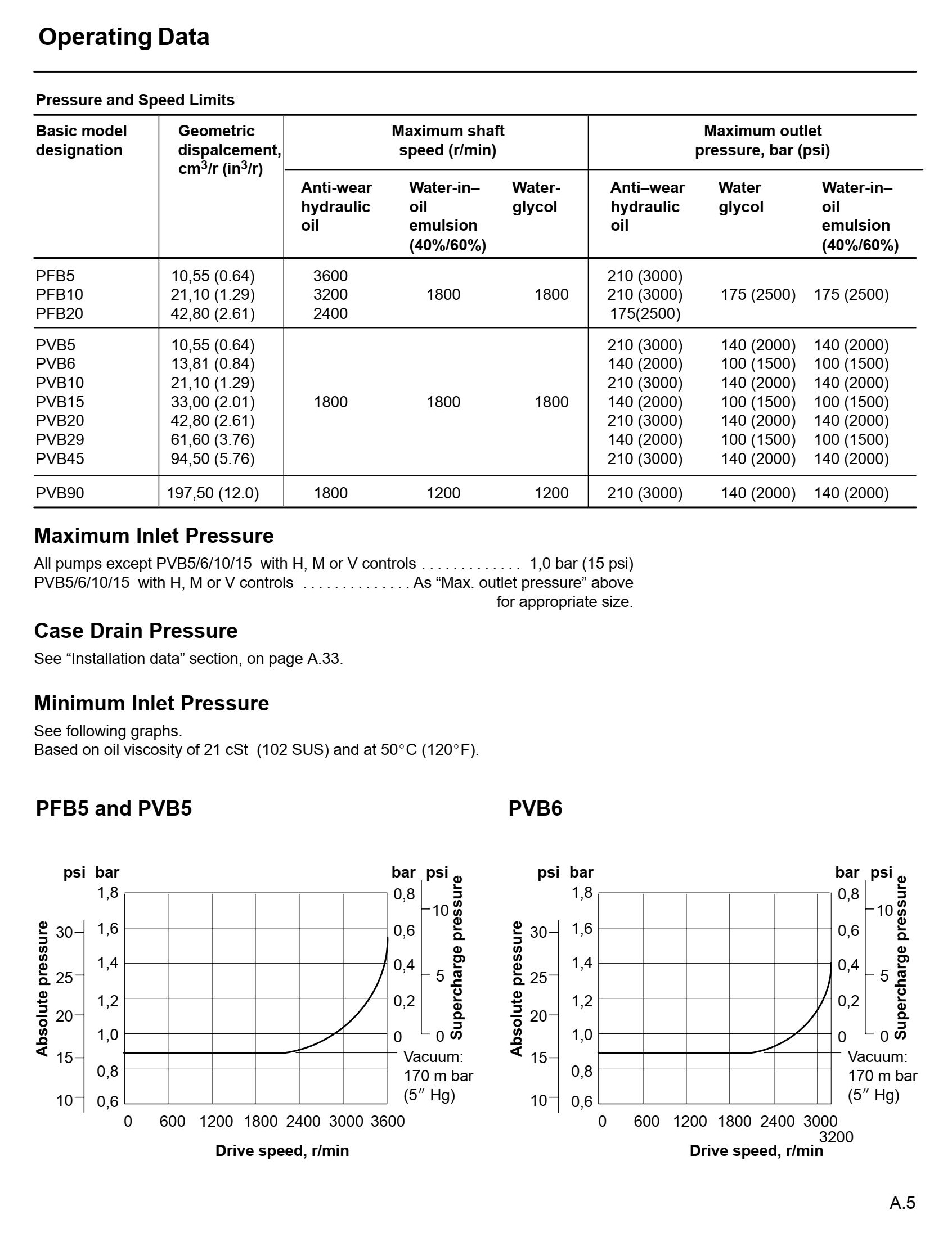

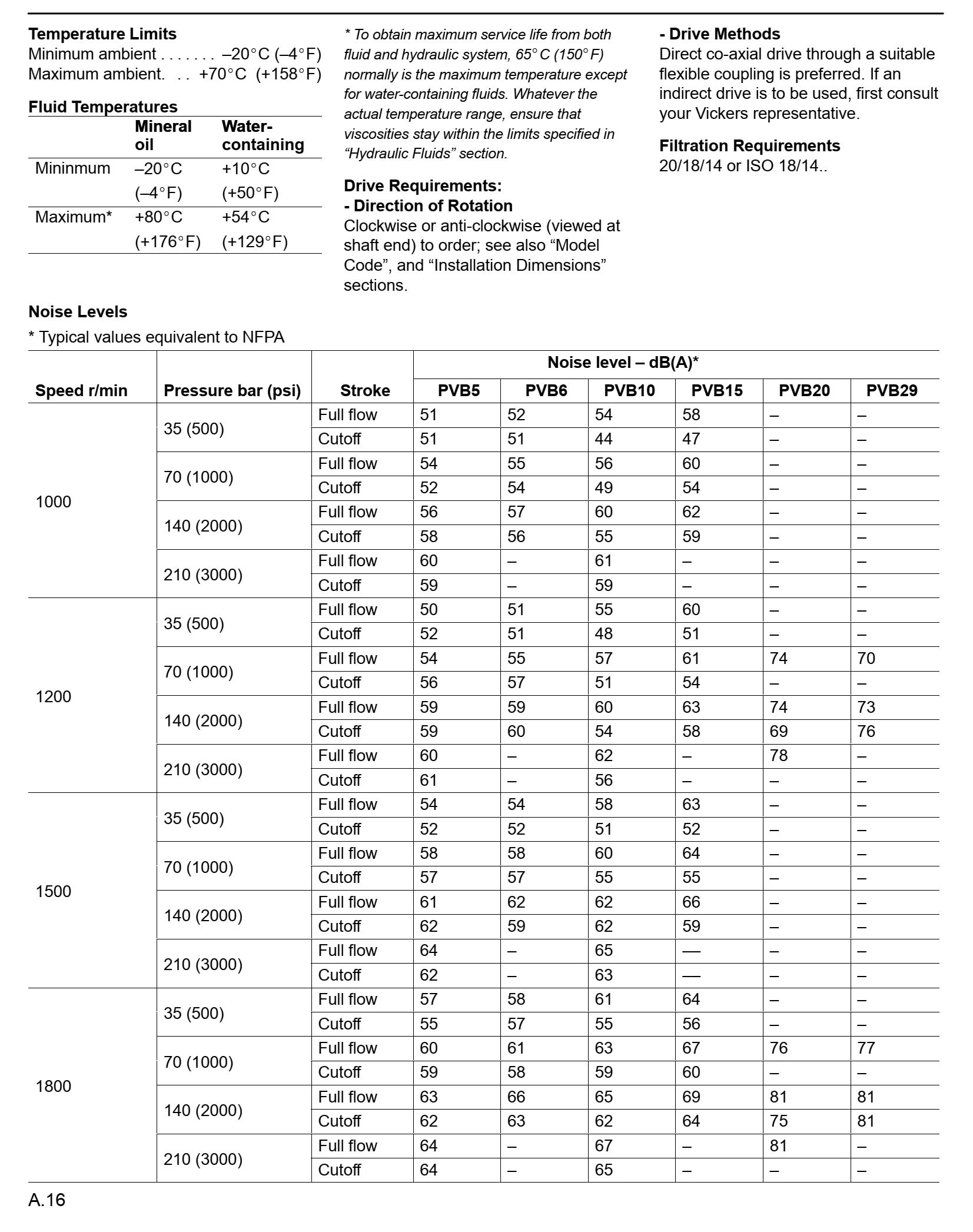

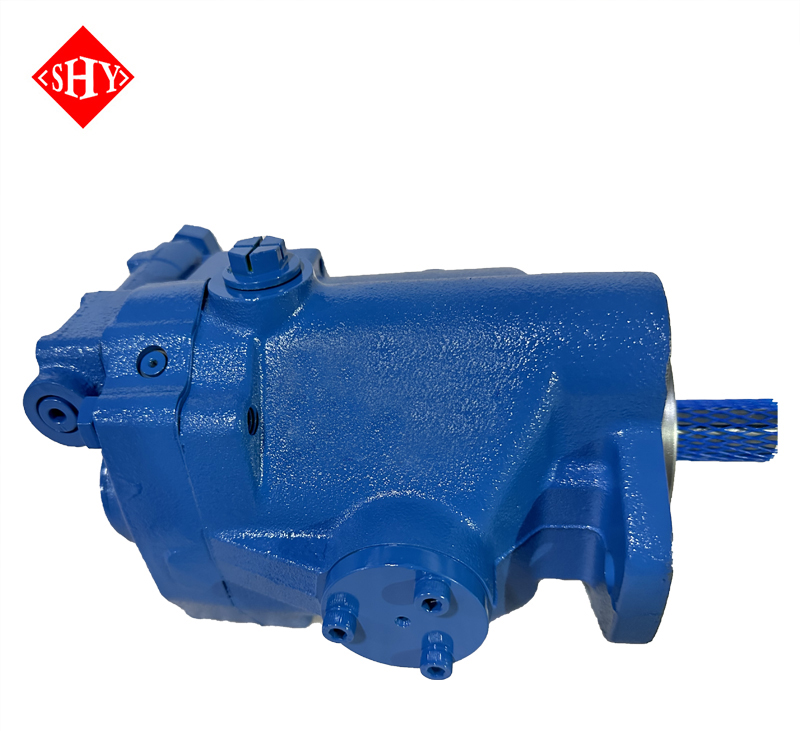

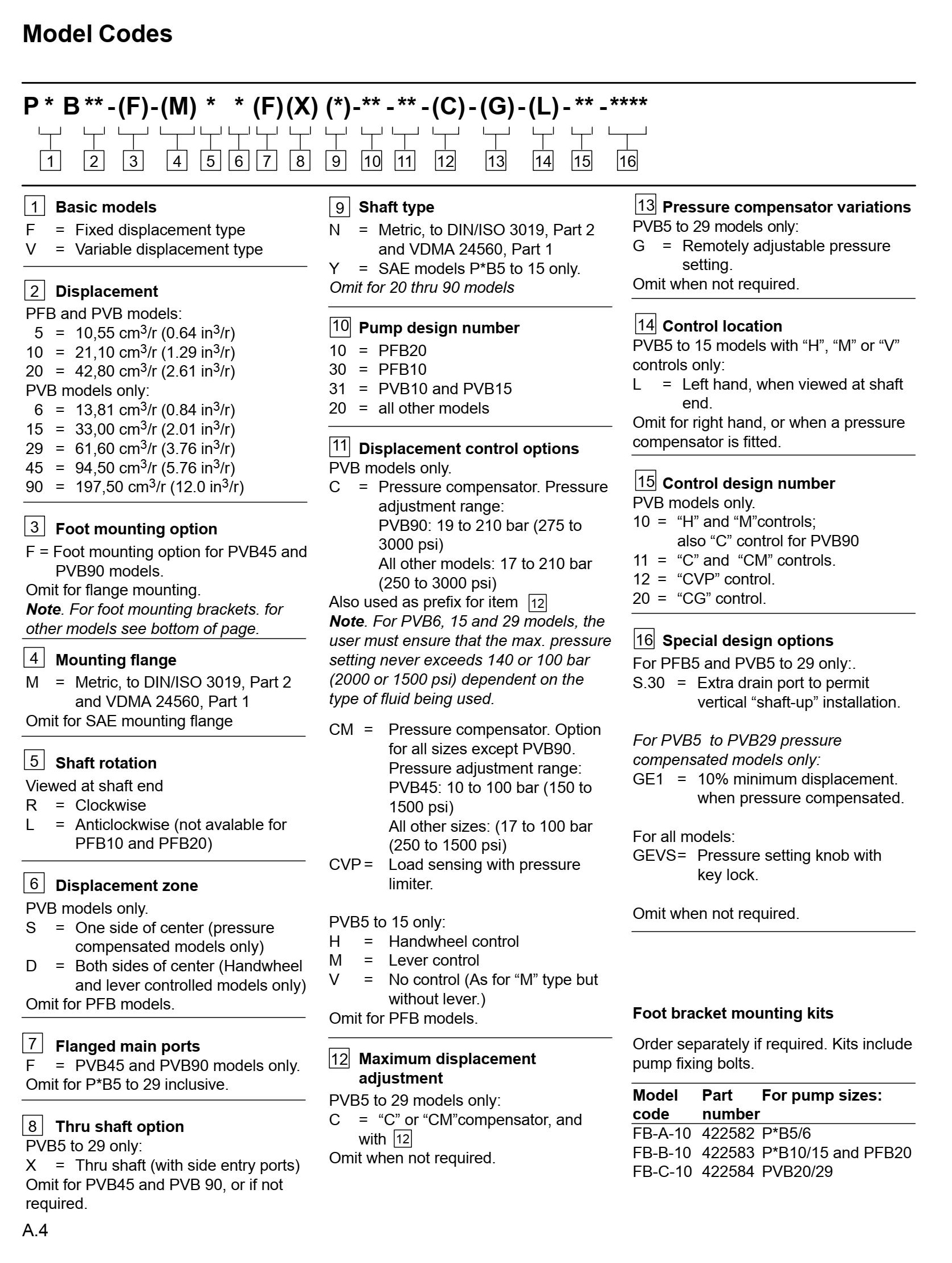

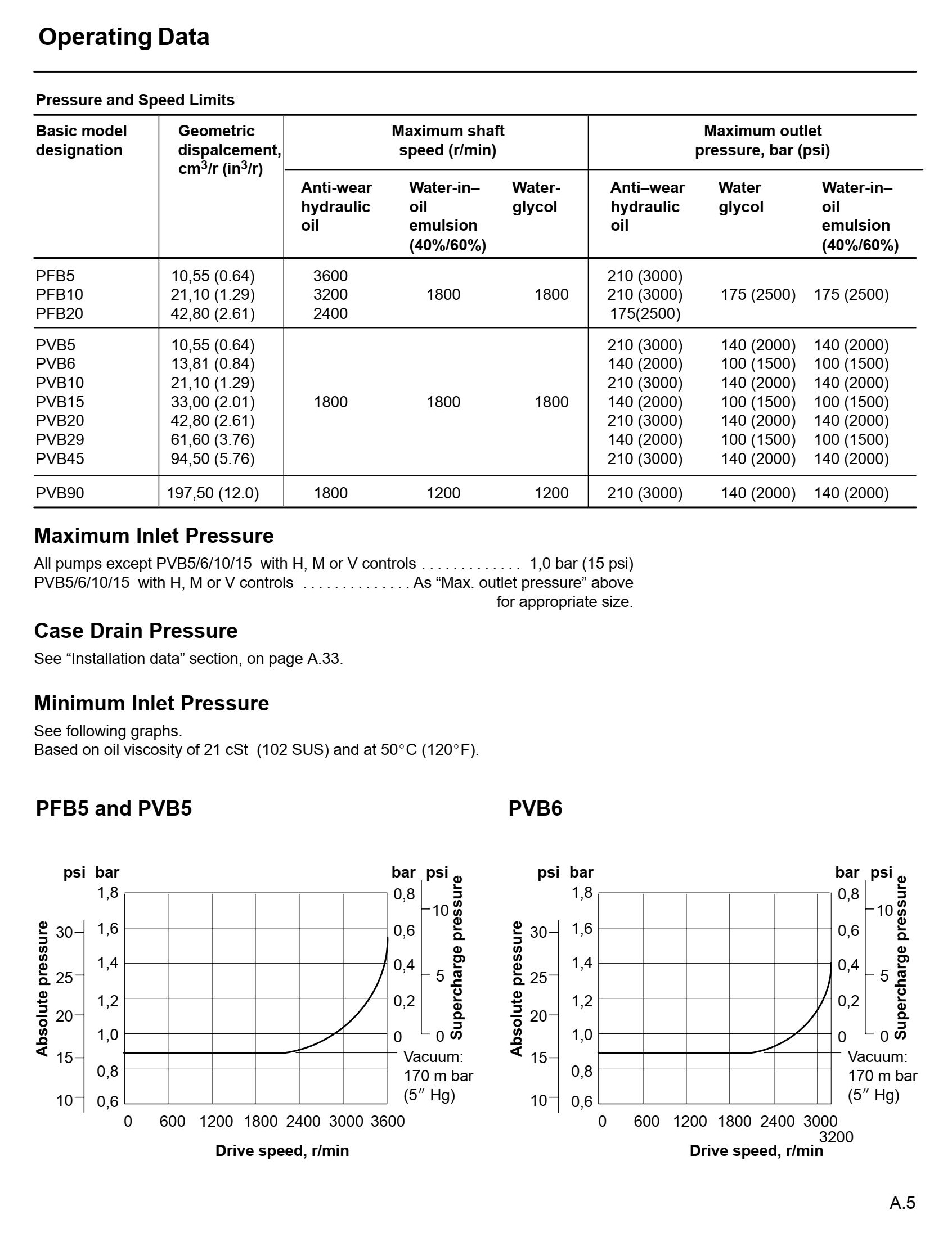

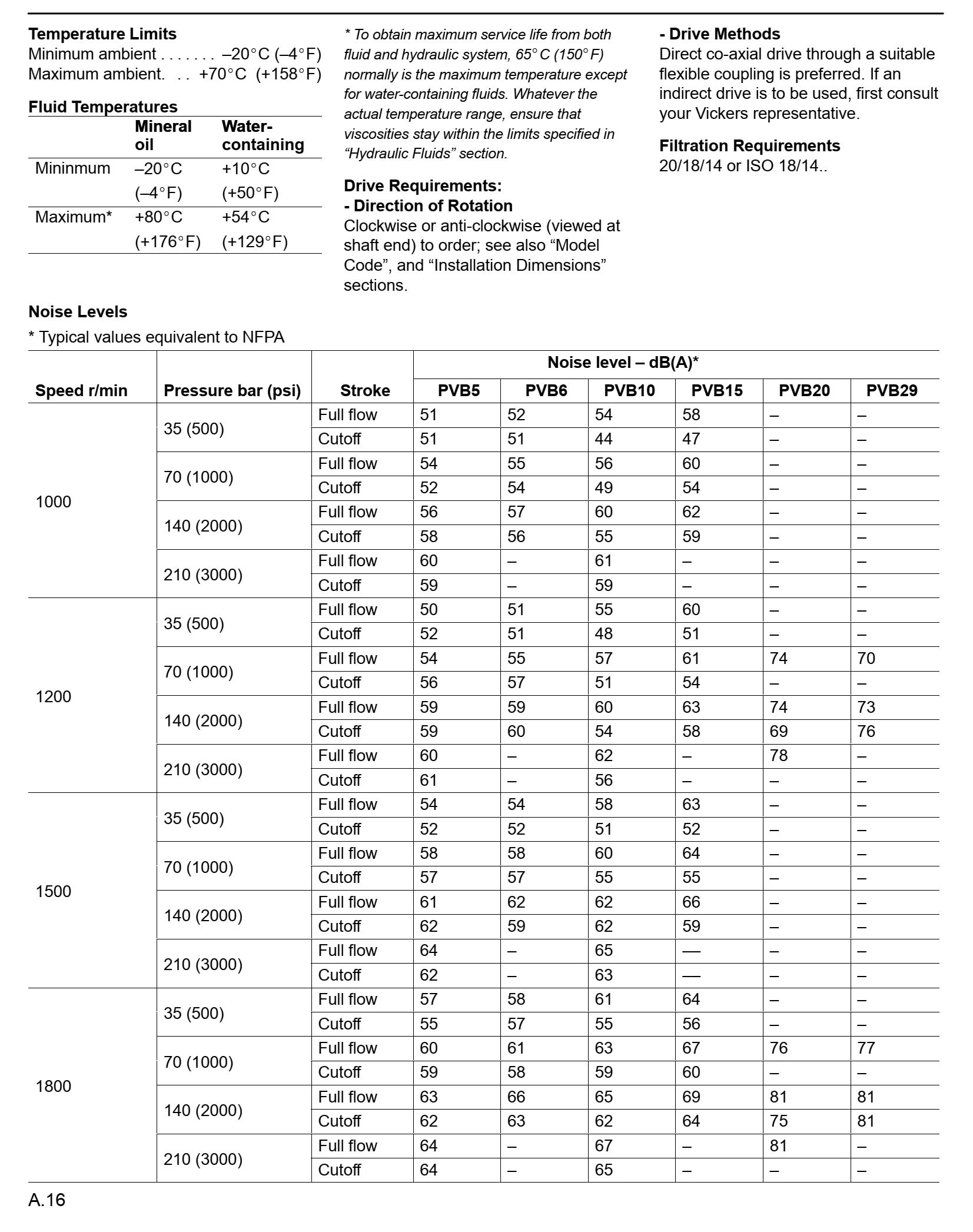

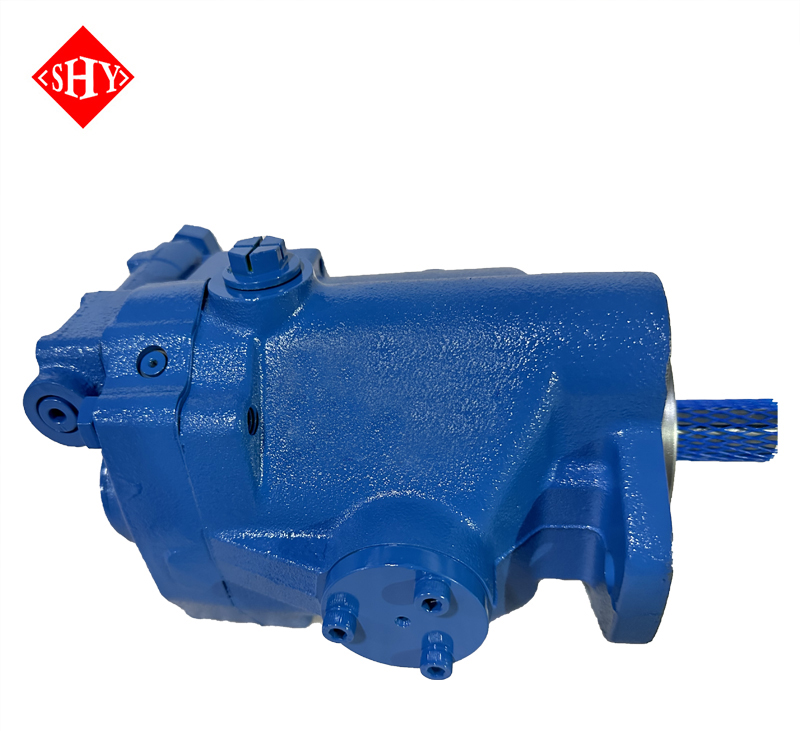

Product Overview

The PVB/PFB High-Pressure Variable Piston Pumps represent Eaton Vickers’ flagship solutions for heavy-duty industrial applications, designed to withstand harsh operating conditions (e.g., dust, vibration, temperature fluctuations). This series includes both variable displacement (PVB) and fixed displacement (PFB) models, engineered with a modular architecture that supports easy replacement of key components (e.g., control valves, seals, pistons) without disassembling the entire pump. With operating pressures up to 210 bar and a service life of over 8,000 hours in typical use, these pumps excel in environments where reliability and durability are non-negotiable. Their modular design supports multiple control options—including pressure compensators, load-sensing technology, and remote proportional control—enabling seamless integration into complex hydraulic circuits (e.g., multi-axis machine tool systems). They are also compatible with ISO VG 46-68 mineral oils and can operate in temperatures from -20°C to 80°C, adapting to steel mills, construction sites, and marine environments.

Product Features

Flexible Displacement Options: PVB variable models cover 10.55 cc to 197.5 cc (PVB5 to PVB150), while PFB fixed models offer 10.55 cc to 42.80 cc (PFB5 to PFB20), ensuring precise matching to system flow demands. For example, the PVB20 (20.7 cc) is ideal for small hydraulic presses, while the PVB150 (197.5 cc) powers large concrete pump booms .

High Pressure Rating: Operates continuously at 210 bar (3,000 psi) with intermittent peaks up to 315 bar (4,568 psi)—sufficient for heavy-load applications like metal forming (200-ton bending machines) and steel rolling (hot strip mill hydraulic rolls). The pump’s cylinder block, made of forged SCM440 steel (tensile strength: 900 MPa), resists deformation under high pressure .

Advanced Control Systems: Available with load-sensing pressure compensators (maintaining pressure 10-15 bar above load demand) and electro-proportional control valves (±1% flow adjustment accuracy), enabling energy savings of up to 20% in variable-load systems. Remote control via 4-20 mA signals also allows integration with PLC-based automation systems (e.g., Siemens S7-1200) .

Wide Speed Compatibility: Functions efficiently at speeds from 900 rpm to 3600 rpm—suitable for both low-speed stationary power units (900 rpm for steel mill auxiliary systems) and high-speed mobile machinery (3600 rpm for construction equipment engines). It features a cold-start protection design (viscosity adapter for low temperatures) that prevents seizure at -20°C .

Applications

Ideal for steel mill rolling equipment (hot strip mill hydraulic gap control, cold rolling mill tension cylinders), hydraulic presses (500-ton capacity metal stamping presses, 300-ton plastic compression molding presses), construction machinery (concrete pump booms, excavator arm lifts), and marine deck machinery (ship anchor winches, cargo crane hydraulic drives). The PVB series is preferred for variable-load systems like injection molding machines (where flow demand fluctuates with mold clamping force), while PFB models excel in stationary power units requiring consistent flow delivery—such as factory centralized hydraulic systems (supplying 10+ machines simultaneously) and test benches for hydraulic components.

Hydraulic pump PVB PFB series PFB5 PFB10 PFB20

PVB5 PVB6 PVB10 PVB15 PVB20 PVB29 PVB45

PVB90 hydraulic variable piston pump

Basic Characteristics

Type Axial piston pumps

Operating pressureup to 210 bar(3000 psi)

Displacement10,5 to 197,5 cm3/r(0.64 to 12 in3/r)

Drive speedup to 3600 r/min

Typical Section

Variable displacement model with compensator control "C" or "CM"

Product Overview

The PVB/PFB High-Pressure Variable Piston Pumps represent Eaton Vickers’ flagship solutions for heavy-duty industrial applications, designed to withstand harsh operating conditions (e.g., dust, vibration, temperature fluctuations). This series includes both variable displacement (PVB) and fixed displacement (PFB) models, engineered with a modular architecture that supports easy replacement of key components (e.g., control valves, seals, pistons) without disassembling the entire pump. With operating pressures up to 210 bar and a service life of over 8,000 hours in typical use, these pumps excel in environments where reliability and durability are non-negotiable. Their modular design supports multiple control options—including pressure compensators, load-sensing technology, and remote proportional control—enabling seamless integration into complex hydraulic circuits (e.g., multi-axis machine tool systems). They are also compatible with ISO VG 46-68 mineral oils and can operate in temperatures from -20°C to 80°C, adapting to steel mills, construction sites, and marine environments.

Product Features

Flexible Displacement Options: PVB variable models cover 10.55 cc to 197.5 cc (PVB5 to PVB150), while PFB fixed models offer 10.55 cc to 42.80 cc (PFB5 to PFB20), ensuring precise matching to system flow demands. For example, the PVB20 (20.7 cc) is ideal for small hydraulic presses, while the PVB150 (197.5 cc) powers large concrete pump booms .

High Pressure Rating: Operates continuously at 210 bar (3,000 psi) with intermittent peaks up to 315 bar (4,568 psi)—sufficient for heavy-load applications like metal forming (200-ton bending machines) and steel rolling (hot strip mill hydraulic rolls). The pump’s cylinder block, made of forged SCM440 steel (tensile strength: 900 MPa), resists deformation under high pressure .

Advanced Control Systems: Available with load-sensing pressure compensators (maintaining pressure 10-15 bar above load demand) and electro-proportional control valves (±1% flow adjustment accuracy), enabling energy savings of up to 20% in variable-load systems. Remote control via 4-20 mA signals also allows integration with PLC-based automation systems (e.g., Siemens S7-1200) .

Wide Speed Compatibility: Functions efficiently at speeds from 900 rpm to 3600 rpm—suitable for both low-speed stationary power units (900 rpm for steel mill auxiliary systems) and high-speed mobile machinery (3600 rpm for construction equipment engines). It features a cold-start protection design (viscosity adapter for low temperatures) that prevents seizure at -20°C .

Applications

Ideal for steel mill rolling equipment (hot strip mill hydraulic gap control, cold rolling mill tension cylinders), hydraulic presses (500-ton capacity metal stamping presses, 300-ton plastic compression molding presses), construction machinery (concrete pump booms, excavator arm lifts), and marine deck machinery (ship anchor winches, cargo crane hydraulic drives). The PVB series is preferred for variable-load systems like injection molding machines (where flow demand fluctuates with mold clamping force), while PFB models excel in stationary power units requiring consistent flow delivery—such as factory centralized hydraulic systems (supplying 10+ machines simultaneously) and test benches for hydraulic components.

Hydraulic pump PVB PFB series PFB5 PFB10 PFB20

PVB5 PVB6 PVB10 PVB15 PVB20 PVB29 PVB45

PVB90 hydraulic variable piston pump

Basic Characteristics

Type Axial piston pumps

Operating pressureup to 210 bar(3000 psi)

Displacement10,5 to 197,5 cm3/r(0.64 to 12 in3/r)

Drive speedup to 3600 r/min

Typical Section

Variable displacement model with compensator control "C" or "CM"