| Availability: | |

|---|---|

| Quantity: | |

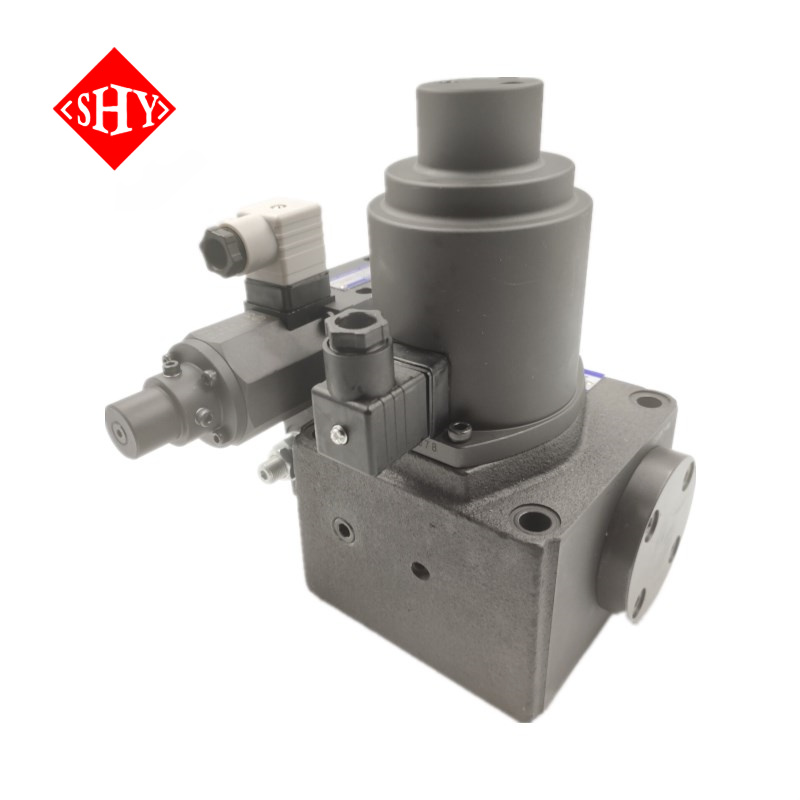

We reaching out to propose a collaborative approach aimed at improving the operational reliability and service life of EFBG valves within your systems. By focusing on optimized selection, precise installation, diligent maintenance, and effective environmental management, we can work together to minimize failures and maximize performance.

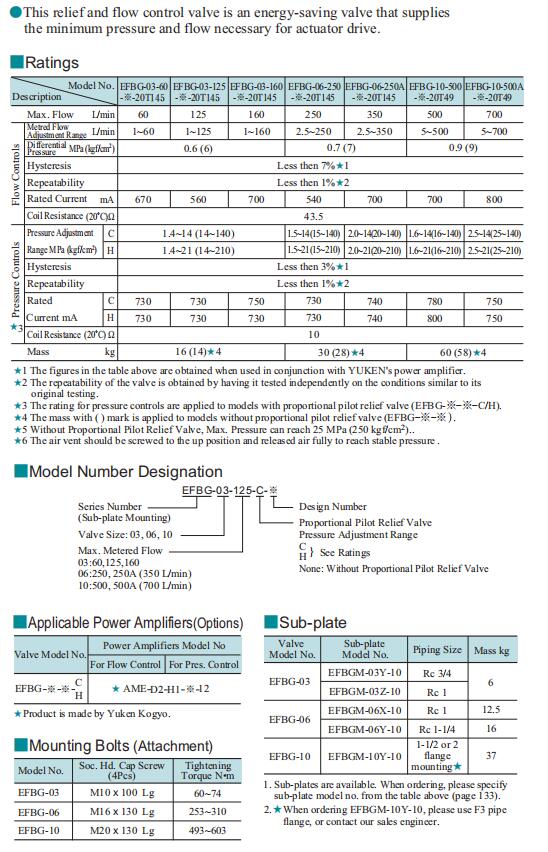

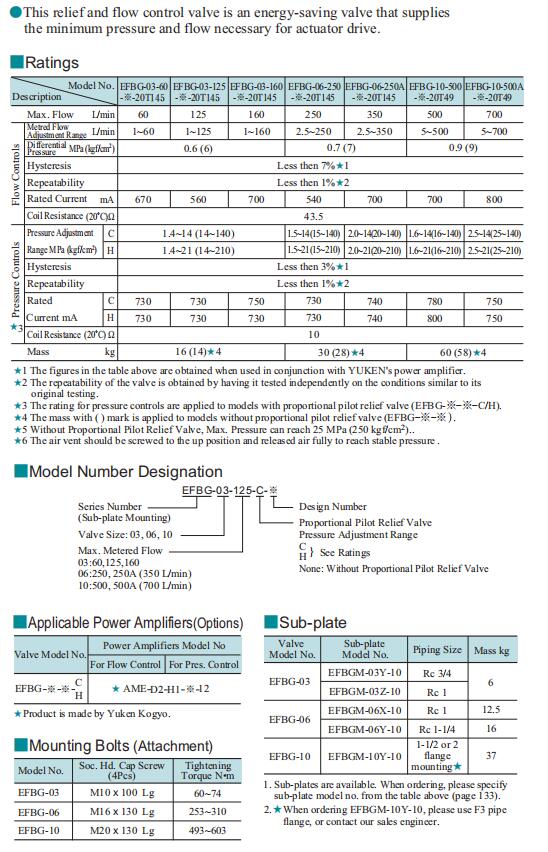

The foundation of long-term valve performance begins with proper selection. It is essential to match the EFBG valve specifications precisely to the system’s operating conditions—including working pressure, temperature, and media type. Ensuring that the valve’s rated parameters align with actual field requirements significantly reduces the risk of premature failure and enhances system safety.

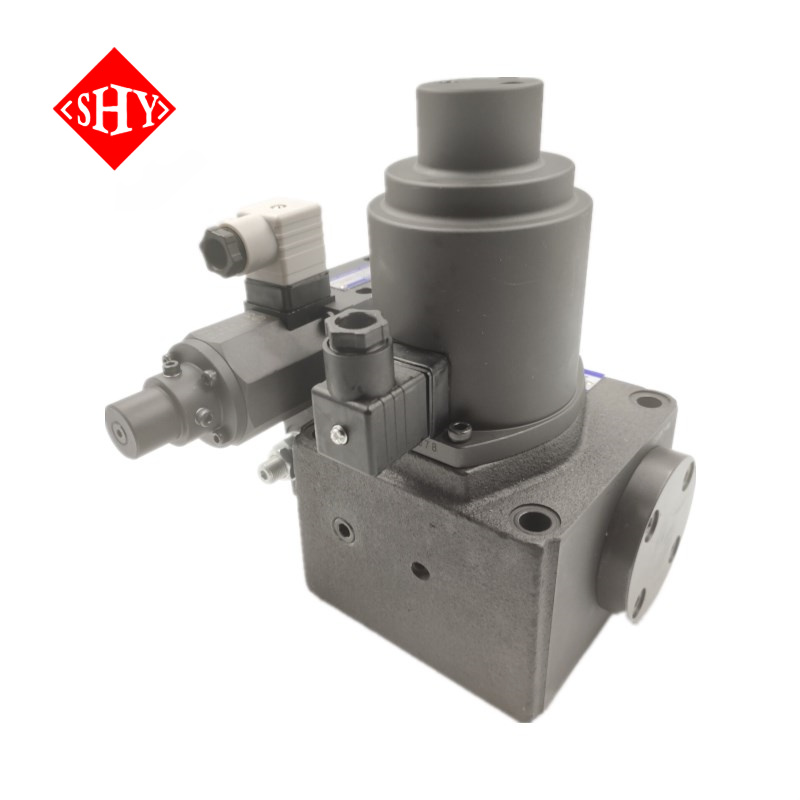

Equally critical is the installation and commissioning phase. Adhering strictly to manufacturer guidelines ensures correct positioning and stress-free connections between pipelines and the valve. Misalignment or mechanical stress during installation can lead to operational issues and accelerated wear. Following installation, comprehensive commissioning—including verification of actuator responsiveness, stroke accuracy, and limit switch calibration—is vital to confirm full functionality prior to service entry.

In continuous operation, a structured maintenance strategy plays a decisive role. We recommend implementing routine visual inspections to detect early signs of leakage, corrosion, or physical damage. Additionally, regular lubrication of moving parts and cleaning of the valve and surrounding area contribute to smooth, uninterrupted operation. Monitoring key control parameters—such as valve position signals, power supply stability, and actuator response—enables real-time diagnostics and proactive intervention. To further minimize downtime, establishing a robust spare parts inventory for critical components like valve cores, seats, seals, and actuator wear parts is strongly advised.

For installations in challenging environments—such as those involving high temperatures, humidity, or excessive dust—proactive environmental protection measures are essential. Solutions such as heat shielding, ventilation systems, and dehumidification equipment can significantly extend valve service life. Preventing prolonged exposure to extreme conditions helps avoid material degradation caused by thermal cycling or moisture ingress.

By integrating these best practices across the valve lifecycle, we can collectively reduce unplanned outages, lower maintenance costs, and improve overall system efficiency.

We reaching out to propose a collaborative approach aimed at improving the operational reliability and service life of EFBG valves within your systems. By focusing on optimized selection, precise installation, diligent maintenance, and effective environmental management, we can work together to minimize failures and maximize performance.

The foundation of long-term valve performance begins with proper selection. It is essential to match the EFBG valve specifications precisely to the system’s operating conditions—including working pressure, temperature, and media type. Ensuring that the valve’s rated parameters align with actual field requirements significantly reduces the risk of premature failure and enhances system safety.

Equally critical is the installation and commissioning phase. Adhering strictly to manufacturer guidelines ensures correct positioning and stress-free connections between pipelines and the valve. Misalignment or mechanical stress during installation can lead to operational issues and accelerated wear. Following installation, comprehensive commissioning—including verification of actuator responsiveness, stroke accuracy, and limit switch calibration—is vital to confirm full functionality prior to service entry.

In continuous operation, a structured maintenance strategy plays a decisive role. We recommend implementing routine visual inspections to detect early signs of leakage, corrosion, or physical damage. Additionally, regular lubrication of moving parts and cleaning of the valve and surrounding area contribute to smooth, uninterrupted operation. Monitoring key control parameters—such as valve position signals, power supply stability, and actuator response—enables real-time diagnostics and proactive intervention. To further minimize downtime, establishing a robust spare parts inventory for critical components like valve cores, seats, seals, and actuator wear parts is strongly advised.

For installations in challenging environments—such as those involving high temperatures, humidity, or excessive dust—proactive environmental protection measures are essential. Solutions such as heat shielding, ventilation systems, and dehumidification equipment can significantly extend valve service life. Preventing prolonged exposure to extreme conditions helps avoid material degradation caused by thermal cycling or moisture ingress.

By integrating these best practices across the valve lifecycle, we can collectively reduce unplanned outages, lower maintenance costs, and improve overall system efficiency.