| Availability: | |

|---|---|

| Quantity: | |

Product Overview

The Replacement A7VO Hydraulic Piston Pump is a high-performance alternative to original A7VO series pumps (compatible with models like A7VO55, A7VO80, A7VO107, A7VO160), designed for industrial machinery that demands consistent pressure and flow—even in variable-speed or fluctuating-load conditions. It supports multiple hydraulic fluid types, including mineral-based oils (ISO VG 32-68), synthetic esters, and fire-resistant hydraulic fluids, making it adaptable to specialized environments (e.g., food processing, high-temperature workshops). This pump also features a modular design, allowing easy replacement of wear parts (e.g., valve plates, pistons) without disassembling the entire unit, reducing maintenance time.

Product Features

Versatile Displacement Options: Covers nominal displacements from 28 cc to 160 cc, with each model compatible with electro-hydraulic proportional valves for precise flow adjustment (control accuracy ±1%). This flexibility enables it to match the needs of both low-flow precision equipment (e.g., 28 cc for small-scale injection molding) and high-flow heavy machinery (e.g., 160 cc for large construction cranes).

High Rated Pressure: Sustains 35 MPa (5,076 psi) for heavy-duty applications like metal processing and construction, with internal leakage below 0.5 L/min at rated pressure—ensuring system pressure stability and preventing energy waste. It also includes a pressure relief valve (set to 40 MPa) to protect against accidental overpressure, enhancing system safety.

Smooth Operation: Equipped with pressure-dependent gap sealing technology, which automatically adjusts the clearance between the valve plate and cylinder block based on operating pressure. This minimizes fluid turbulence and reduces noise levels to below 65 dB(A)—meeting industrial workshop noise standards (ISO 11200) and improving workplace comfort.

Wide Speed Range: Functions efficiently at speeds between 2,560 rpm and 4,250 rpm. At low speeds (2,560 rpm), it maintains torque fluctuation of less than ±3%, ensuring steady operation for precision tasks (e.g., metal cutting). At high speeds (4,250 rpm), its integrated heat dissipation structure keeps operating temperatures below 80℃, preventing oil degradation and component wear.

Applications

Widely used in injection molding machines (plastic bottle preform production lines), metallurgical equipment (continuous casting machines in steel plants), construction machinery (excavator hydraulic arms), and agricultural irrigation systems (large-scale center-pivot irrigation pumps). Its durability makes it suitable for both stationary industrial presses (e.g., 1,000-ton metal stamping machines) and mobile hydraulic units (e.g., road pavers), with a service life of over 6,000 hours in typical operating conditions.

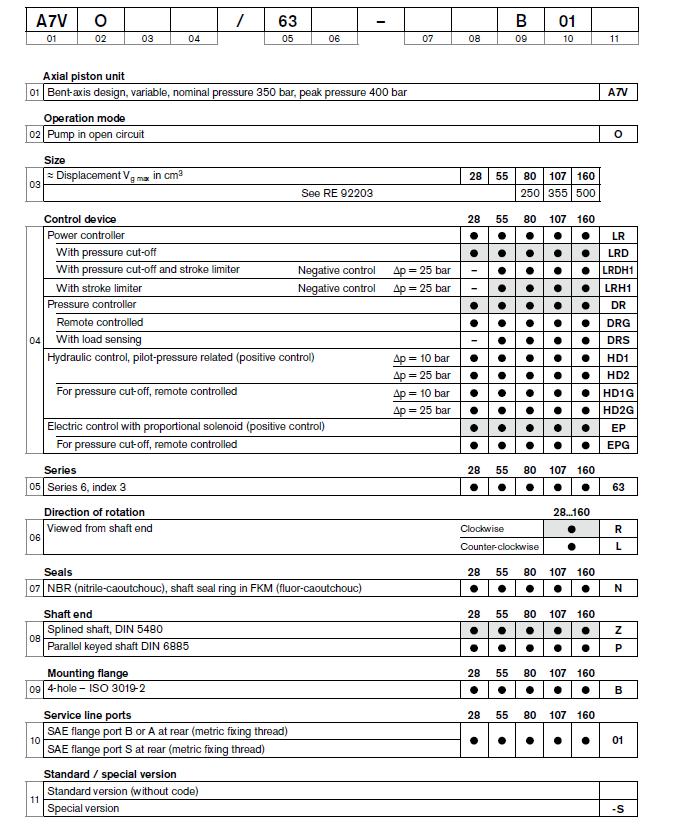

A7VO Pump Order Code:

More Model:

A7VO28LRG/63R-NPB01 | A7VO28DR/63R-NSB01 | A7VO28LR3/63L-NZB01 |

A7VO55DRSX/63L-NZB01-S | A7VO55LR3/63R-NZB01 | A7VO55HD1/63R-NSB01 |

A7VO55EPG/63L-PZB01 | A7VO80DR/63R-NSB01 | A7VO80EP/63R-VZB01 |

A7VO80LRDH1/63L-NZB01 | A7VO80HDD/63R-PZB02 | A7VO107EPG/63R-NZB01 |

A7VO107LRDH1/63R-NZB01 | A7VO107DR/63L-NSB01 | A7VO107HD1/63R-VZB01 |

A7VO160LRDS/63R-NZB01 | A7VO160HD1/63L-NSB01 | A7VO160DRG/63R-PZB02 |

A7VO160EPD/63L-VZH01 | A7VO250HDD/60L-PZB02 | A7VO250EPD/60L-PZB01 |

A7VO250LRDS/60R-NZB01 | A7VO250DR/60L-NSB01 | A7VO355DRG/63R-VPH02 |

A7VO355HD1D/63R-VZH02E | A7VO355LRDS/63L-NZB01 | A7VO355EPD/63R-PZB01 |

A7VO500DR/63R-VZH02 | A7VO500DRG/63R-VPH02E | A7VO500LRDH1/63L-NZB01 |

Product Overview

The Replacement A7VO Hydraulic Piston Pump is a high-performance alternative to original A7VO series pumps (compatible with models like A7VO55, A7VO80, A7VO107, A7VO160), designed for industrial machinery that demands consistent pressure and flow—even in variable-speed or fluctuating-load conditions. It supports multiple hydraulic fluid types, including mineral-based oils (ISO VG 32-68), synthetic esters, and fire-resistant hydraulic fluids, making it adaptable to specialized environments (e.g., food processing, high-temperature workshops). This pump also features a modular design, allowing easy replacement of wear parts (e.g., valve plates, pistons) without disassembling the entire unit, reducing maintenance time.

Product Features

Versatile Displacement Options: Covers nominal displacements from 28 cc to 160 cc, with each model compatible with electro-hydraulic proportional valves for precise flow adjustment (control accuracy ±1%). This flexibility enables it to match the needs of both low-flow precision equipment (e.g., 28 cc for small-scale injection molding) and high-flow heavy machinery (e.g., 160 cc for large construction cranes).

High Rated Pressure: Sustains 35 MPa (5,076 psi) for heavy-duty applications like metal processing and construction, with internal leakage below 0.5 L/min at rated pressure—ensuring system pressure stability and preventing energy waste. It also includes a pressure relief valve (set to 40 MPa) to protect against accidental overpressure, enhancing system safety.

Smooth Operation: Equipped with pressure-dependent gap sealing technology, which automatically adjusts the clearance between the valve plate and cylinder block based on operating pressure. This minimizes fluid turbulence and reduces noise levels to below 65 dB(A)—meeting industrial workshop noise standards (ISO 11200) and improving workplace comfort.

Wide Speed Range: Functions efficiently at speeds between 2,560 rpm and 4,250 rpm. At low speeds (2,560 rpm), it maintains torque fluctuation of less than ±3%, ensuring steady operation for precision tasks (e.g., metal cutting). At high speeds (4,250 rpm), its integrated heat dissipation structure keeps operating temperatures below 80℃, preventing oil degradation and component wear.

Applications

Widely used in injection molding machines (plastic bottle preform production lines), metallurgical equipment (continuous casting machines in steel plants), construction machinery (excavator hydraulic arms), and agricultural irrigation systems (large-scale center-pivot irrigation pumps). Its durability makes it suitable for both stationary industrial presses (e.g., 1,000-ton metal stamping machines) and mobile hydraulic units (e.g., road pavers), with a service life of over 6,000 hours in typical operating conditions.

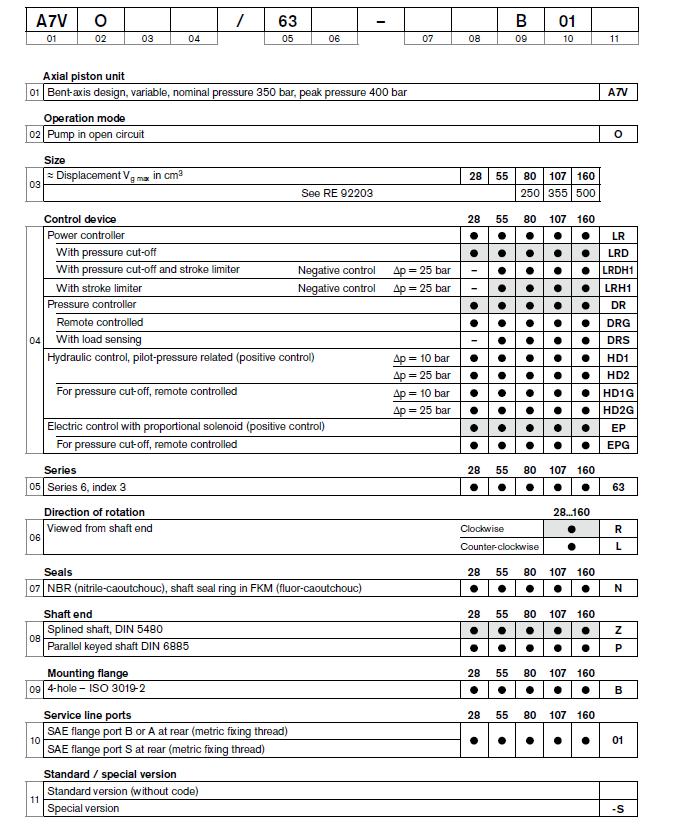

A7VO Pump Order Code:

More Model:

A7VO28LRG/63R-NPB01 | A7VO28DR/63R-NSB01 | A7VO28LR3/63L-NZB01 |

A7VO55DRSX/63L-NZB01-S | A7VO55LR3/63R-NZB01 | A7VO55HD1/63R-NSB01 |

A7VO55EPG/63L-PZB01 | A7VO80DR/63R-NSB01 | A7VO80EP/63R-VZB01 |

A7VO80LRDH1/63L-NZB01 | A7VO80HDD/63R-PZB02 | A7VO107EPG/63R-NZB01 |

A7VO107LRDH1/63R-NZB01 | A7VO107DR/63L-NSB01 | A7VO107HD1/63R-VZB01 |

A7VO160LRDS/63R-NZB01 | A7VO160HD1/63L-NSB01 | A7VO160DRG/63R-PZB02 |

A7VO160EPD/63L-VZH01 | A7VO250HDD/60L-PZB02 | A7VO250EPD/60L-PZB01 |

A7VO250LRDS/60R-NZB01 | A7VO250DR/60L-NSB01 | A7VO355DRG/63R-VPH02 |

A7VO355HD1D/63R-VZH02E | A7VO355LRDS/63L-NZB01 | A7VO355EPD/63R-PZB01 |

A7VO500DR/63R-VZH02 | A7VO500DRG/63R-VPH02E | A7VO500LRDH1/63L-NZB01 |