| Availability: | |

|---|---|

| Quantity: | |

Product Overview

Designed as a direct drop-in solution, the 100% Interchangeable Vickers PVXS Replacement Hydraulic Pump fully matches the performance, dimensional specifications, and interface standards of original Vickers PVXS series pumps—including popular models like PVXS-130, PVXS-180, and PVXS-250. Engineered specifically for industrial high-pressure scenarios, this replacement pump eliminates the need for costly system modifications (such as adjusting interface sizes, hydraulic circuit parameters, or mounting brackets) and ensures seamless compatibility with existing Vickers PVXS-equipped setups. It undergoes rigorous performance calibration to guarantee that flow rate, pressure stability, and response speed align with OEM standards, making it a cost-effective alternative for maintenance and retrofitting projects.

Product Features

High Pressure Capacity: Operates at a rated pressure of 350 bar (5,000 psi) to handle heavy-duty industrial tasks, supporting 24/7 continuous operation without performance degradation. Even under peak load conditions, its pressure retention rate exceeds 98%, minimizing pressure fluctuations that could affect downstream equipment.

Broad Displacement Range: Available in 66 cc to 250 cc (covering PVXS-66, PVXS-100, PVXS-130, PVXS-180, PVXS-250 variants) to meet diverse flow requirements. Each displacement specifications undergoes flow stability testing, with a deviation of less than ±2% from nominal flow, ensuring consistent power delivery for varying industrial processes.

Durable Construction: Built with precision components such as hardened steel cylinder blocks (surface hardness up to HRC 60) and ceramic-coated pistons, which enhance wear resistance by 50% compared to standard steel parts. The pump also features a multi-layer oil seal design that resists contamination from dust, moisture, and particulate matter, extending service life to over 8,000 operating hours in harsh environments (e.g., high humidity, dusty workshops).

Energy Efficiency: Optimized hydraulic circuits reduce internal leakage and heat loss, achieving up to 95% efficiency during continuous operation. Compared to aging original Vickers PVXS pumps (typically 85-90% efficient), this replacement model cuts energy consumption by 12%, translating to approximately 3,000 kWh in annual electricity savings for a medium-sized manufacturing facility.

Applications

Ideal for industries requiring robust hydraulic power, including metal forming (e.g., automotive chassis stamping lines), tube bending (for stainless steel pipe fabrication in construction), hydraulic presses (used in aerospace component molding), marine winches (deck lifting systems for cargo ships), and chemical mixing equipment (high-torque agitators in petrochemical plants). Its 100% interchangeability makes it a preferred choice for retrofitting aging Vickers PVXS systems in industries where downtime must be minimized—installations can be completed in under 4 hours, reducing production interruptions.

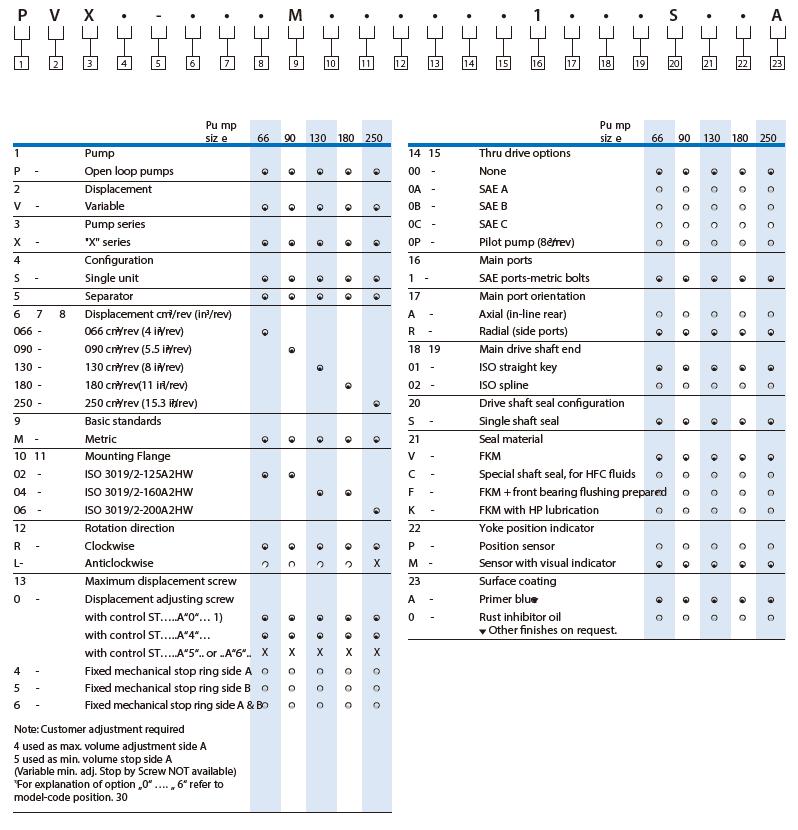

PVXS Series Pump Order Code:

More model:

PVXS-066M02R0001R01SVVADF000A0000000000000000015

PVXS-180M04R0001R01SVVADF000A0000000000000000015

PVXS-130M04R0001R01SLVADF000A0S00000000000000015

PVXS-090M02R0001R01SVVADF000A0000000000000000010

PVXS-250M06R0001R01SVVADF000A0000000000000000010

PVXS-180M04R0001R01SVVALR000A2008200000000000

PVXS-180M04R0001R01SVVAD000A0000000000030009010

PVXS-130M04R0001R01SVVADF000A0000000000000000010

Product Overview

Designed as a direct drop-in solution, the 100% Interchangeable Vickers PVXS Replacement Hydraulic Pump fully matches the performance, dimensional specifications, and interface standards of original Vickers PVXS series pumps—including popular models like PVXS-130, PVXS-180, and PVXS-250. Engineered specifically for industrial high-pressure scenarios, this replacement pump eliminates the need for costly system modifications (such as adjusting interface sizes, hydraulic circuit parameters, or mounting brackets) and ensures seamless compatibility with existing Vickers PVXS-equipped setups. It undergoes rigorous performance calibration to guarantee that flow rate, pressure stability, and response speed align with OEM standards, making it a cost-effective alternative for maintenance and retrofitting projects.

Product Features

High Pressure Capacity: Operates at a rated pressure of 350 bar (5,000 psi) to handle heavy-duty industrial tasks, supporting 24/7 continuous operation without performance degradation. Even under peak load conditions, its pressure retention rate exceeds 98%, minimizing pressure fluctuations that could affect downstream equipment.

Broad Displacement Range: Available in 66 cc to 250 cc (covering PVXS-66, PVXS-100, PVXS-130, PVXS-180, PVXS-250 variants) to meet diverse flow requirements. Each displacement specifications undergoes flow stability testing, with a deviation of less than ±2% from nominal flow, ensuring consistent power delivery for varying industrial processes.

Durable Construction: Built with precision components such as hardened steel cylinder blocks (surface hardness up to HRC 60) and ceramic-coated pistons, which enhance wear resistance by 50% compared to standard steel parts. The pump also features a multi-layer oil seal design that resists contamination from dust, moisture, and particulate matter, extending service life to over 8,000 operating hours in harsh environments (e.g., high humidity, dusty workshops).

Energy Efficiency: Optimized hydraulic circuits reduce internal leakage and heat loss, achieving up to 95% efficiency during continuous operation. Compared to aging original Vickers PVXS pumps (typically 85-90% efficient), this replacement model cuts energy consumption by 12%, translating to approximately 3,000 kWh in annual electricity savings for a medium-sized manufacturing facility.

Applications

Ideal for industries requiring robust hydraulic power, including metal forming (e.g., automotive chassis stamping lines), tube bending (for stainless steel pipe fabrication in construction), hydraulic presses (used in aerospace component molding), marine winches (deck lifting systems for cargo ships), and chemical mixing equipment (high-torque agitators in petrochemical plants). Its 100% interchangeability makes it a preferred choice for retrofitting aging Vickers PVXS systems in industries where downtime must be minimized—installations can be completed in under 4 hours, reducing production interruptions.

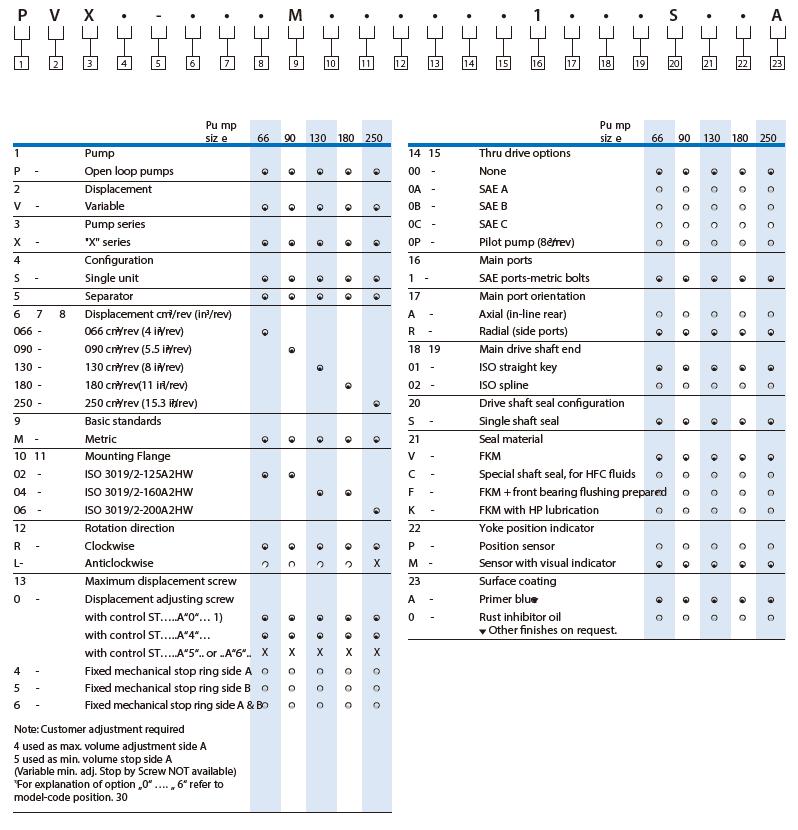

PVXS Series Pump Order Code:

More model:

PVXS-066M02R0001R01SVVADF000A0000000000000000015

PVXS-180M04R0001R01SVVADF000A0000000000000000015

PVXS-130M04R0001R01SLVADF000A0S00000000000000015

PVXS-090M02R0001R01SVVADF000A0000000000000000010

PVXS-250M06R0001R01SVVADF000A0000000000000000010

PVXS-180M04R0001R01SVVALR000A2008200000000000

PVXS-180M04R0001R01SVVAD000A0000000000030009010

PVXS-130M04R0001R01SVVADF000A0000000000000000010