Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

A hydraulic motor is a machine that changes fluid power into spinning movement. It helps machines lift or move heavy things easily. You can see hydraulic motors in machines for building, mining, and farming. They give strong and steady force, even when it is hard to work. These motors are good in places where electric motors do not work well.

Xiamen Senhengyuan Machinery Equipment Co., Ltd. is a trusted place to get hydraulic motors and help. We work hard to give you great products that fit what you need. We also check our products carefully and help our customers well.

The world market for hydraulic motors is growing fast.

The market size in 2024 is USD 12.86 billion.

The market size by 2033 will be USD 18.40 billion.

The growth rate from 2025 to 2033 is 3.85%.

Tip: Hydraulic motors give strong power, last a long time, and are easy to control. This makes them a good pick for many jobs.

Hydraulic motors change fluid power into spinning motion. They are great for lifting heavy things. People use them in building, farming, and factories.

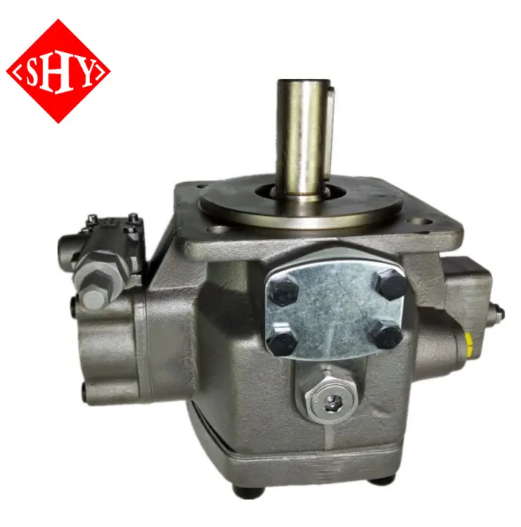

There are three main types of hydraulic motors. These are gear, vane, and piston. Each type works best for different jobs. Each one has its own special benefits.

It is very important to take care of hydraulic motors. Keep the fluid clean at all times. Always check for leaks. Watch the pressure to help the motor last longer.

Picking the right hydraulic motor is important. Think about torque, speed, pressure, and size. This helps your system work safely and well.

Xiamen Senhengyuan Machinery Equipment Co., Ltd. sells good hydraulic motors. They give expert help so you get the right one for your needs.

A hydraulic motor is a machine that uses moving fluid to make things spin. It helps machines move or lift things by using liquid power. In machines, people call it a mechanical actuator. It changes hydraulic pressure and flow into spinning force and turning. This makes it work with a hydraulic cylinder, which moves things in a straight line.

Hydraulic motors are found in many machines that need strong, steady movement. These motors work well in hard places where other motors might break. When you use a hydraulic motor, your equipment moves smoothly and with a lot of power.

The main job of a hydraulic motor is to use pressurized fluid to make things spin. This means the motor helps your machine turn or move parts in a circle. Here is how it works in easy steps:

The hydraulic pump sends high-pressure fluid into the motor.

The fluid pushes on parts inside the motor, like gears, vanes, or pistons.

These parts move and turn the shaft of the motor.

The shaft gives power to the machine so it can work.

You can see the types of hydraulic motors and what they do in the table below:

Type of Motor | Function |

|---|---|

Gear Motor | Uses gears to turn fluid pressure into spinning motion. |

Vane Motor | Uses vanes to make spinning motion from pressurized fluid. |

Piston Motor | Uses pistons to change fluid energy into work. |

Note: Hydraulic motors work by turning high-energy fluid into spinning motion. The pressurized fluid from the pump pushes on the inside parts. This makes the shaft turn and gives your machine power to move.

At Xiamen Senhengyuan Machinery Equipment Co., Ltd., you get more than just a hydraulic motor. You get a product that is made with high quality and works well. We have many kinds of motors, like gear, vane, and piston types. Each motor is checked and tested carefully. Our team looks at every part to make sure your motor lasts long and works great.

We also have important certifications like ISO 9001 and CE. These show we care about safety and quality. Our motors fit many jobs, from small machines to big industrial systems. You can pick from different models and sizes, or ask us for a special one. Our customer service team is ready to help you choose the best motor for your needs.

Tip: When you pick our hydraulic motors, you get strong power, smooth running, and good support. We want to build a long partnership with you, based on trust and value.

Hydraulic motors change fluid power into spinning movement. You can see how this happens by looking at each step. When you know these steps, you can use your hydraulic system safely and get good results.

Hydraulic motors use pressurized fluid to move parts inside. This makes the shaft turn and creates rotary motion. Here is how it works:

First, hydraulic fluid goes into the motor. The fluid comes from a pump in your system. The pump pushes the fluid through hoses and pipes.

Make sure the fluid is clean and hoses are not leaking.

Always check the pressure before you start.

The fluid enters the motor and builds up pressure. This pressure gives the motor its power. More pressure means more force for the motor.

Keep pressure safe to stop damage.

Never touch or remove parts when the system has pressure.

Inside the motor, the fluid pushes on gears, vanes, or pistons. These parts move because of the fluid’s force.

Keep moving parts clean and free from dirt.

Check often to stop wear and keep the motor working well.

The moving parts turn the shaft. This makes rotary motion, which powers other machine parts.

Rotary motion lets you lift, spin, or drive things.

Watch for leaks or strange sounds, which can mean trouble.

Tip: Hydraulic motors work the opposite way of hydraulic pumps. If you use more fluid, the motor spins faster. The load and resistance can change how well the motor works.

You can break down how hydraulic motors turn fluid energy into spinning movement. Each step shows how the motor changes fluid power into mechanical power.

The flow of hydraulic fluid makes force inside the motor. The fluid pushes on the inside parts.

Clean fluid helps the motor work better.

Dirty fluid can hurt the motor and make it less efficient.

The force from the fluid moves the gears, vanes, or pistons. These parts start to turn or slide.

Smooth movement means less energy is lost.

Friction and wear can slow the motor down.

The moving parts change the force into rotary motion. The shaft starts to spin.

Good seals and bearings help the motion stay smooth.

Leaks or worn parts can make the motor less efficient.

The spinning shaft sends power to your machine. You use this power to do work, like lifting or driving.

Always control the pressure to stop overheating.

Listen for noise or shaking, which can mean a problem.

Note: Hydraulic motors use positive displacement. If you increase the flow rate, the motor spins faster. The motor’s design affects how well it turns fluid power into mechanical power. Better seals and smooth parts help save energy.

You need to keep your hydraulic motor safe and working well. Here are some things to watch for:

Never remove or adjust parts when the motor is running.

Always release pressure before you work on the system.

Watch for small leaks in hoses, which can spray fluid and hurt you.

Use the right fluid and keep it clean to stop contamination.

Check filters often to stop clogs and wear.

Cause Type | Description |

|---|---|

Pump-Related Issues | Worn pumps and cavitation cause leaks inside, lowering pressure and flow. |

Fluid-Related Problems | Dirty or wrong fluids cause leaks inside and lower efficiency. |

Filtration Issues | Clogged filters drop pressure and let dirt in, wearing out parts. |

Valve and Control Issues | Leaks in valves and wrong settings limit flow, lowering power. |

Tip: You can make your motor work better by using good bearings and seals. Regular checks help your hydraulic motor last longer and work well.

Hydraulic motors have two main types of efficiency: volumetric and mechanical. Volumetric efficiency shows how well the motor turns fluid into movement. Mechanical efficiency tells how much energy is lost to friction. Motors with good seals and smooth parts give better results.

Safety first! Always check for leaks, keep the fluid clean, and follow the right steps for care. This helps you stay safe and keeps your hydraulic motor working well.

Hydraulic motors have many parts that work together. These parts help the motor make strong and steady movement. You should know about the housing, shaft, and inside parts. This helps you understand how your hydraulic system works well.

The housing is the outside shell of the hydraulic motor. It keeps the inside parts safe from dirt and water. The housing also holds the fluid inside and stops leaks. A strong housing helps the motor last longer and stay safe. At our company, we check every housing for cracks or weak spots. We use good materials so your hydraulic motor can handle hard work.

The shaft is the part that spins and gives power to your machine. You connect the shaft to other parts to make things move. Shafts must be strong and smooth for heavy loads and fast speeds. We use different materials and treatments to make shafts tough:

Surface Treatment | Benefits |

|---|---|

Nitriding | Makes the surface harder and stops wear |

Carburizing | Makes the outside hard but keeps the inside strong |

Induction Hardening | Makes the surface hard for better wear |

Chromium Plating | Adds a tough layer that stops rust |

Some shafts are made from steel to be strong. Others use aluminum to be lighter. We also add coatings like nickel or chrome to stop rust. Our team checks every shaft to make sure it is straight and strong before it leaves.

The inside parts turn fluid power into spinning motion. There are different designs inside hydraulic motors:

Gear motors use gears to make things move. The size of the gears and the fluid pressure decide the force.

Vane motors use sliding vanes. This design helps the motor move smoothly, even at slow speeds.

Piston motors use pistons to make high torque. The number of pistons and how far they move changes the power.

Each type handles pressure and torque in its own way. We test every inside part to make sure it works well and lasts long. Our checks look for wear, smooth movement, and good seals.

Tip: When you pick a hydraulic motor from us, you get a product that passes strict checks. We make sure every part is safe and works well.

There are a few main types of hydraulic motors. Each type works in its own way and is good for certain jobs. Knowing the differences helps you pick the right motor.

Gear motors have gears inside that turn fluid power into spinning. These motors are often used in farm machines. They are small and do not cost much. Gear motors give strong torque and work well.

Here are some good and bad things about gear motors:

Advantages | Disadvantages |

|---|---|

Make strong torque | Not very efficient |

Work with many speeds and torque | Hard to fix |

Last a long time and are reliable | Can pollute the environment |

Can be noisy |

You can find gear motors in our 101, 106, 104, and 158 series. We can pack your order in a special way if you buy 10 or more. If you need a special size or shape, just ask us.

Vane motors use sliding vanes to make smooth spinning. You can control them well, which is good for robots and machine tools. These motors are best when you need steady speed and soft movement.

People use vane motors for:

Factory machines

Robots

Machine tools

Making plastic parts

Our vane motors come in many sizes and models. We can pack your order in a special way. We check every motor to make sure it works well and is high quality.

Piston motors use pistons to give strong torque and power. You see these motors in big machines like diggers and cranes. Piston motors work better and last longer.

Here are some things that make piston motors special:

Feature | Description |

|---|---|

Strong at slow speeds and high torque | Radial piston motors give a lot of torque, so you do not need extra gears. |

Less energy loss | The design spreads out the force, so there is less friction and less wear on bearings. |

Lasts long and works well | Radial piston motors keep working well for a long time, even with hard jobs. |

We have piston motors in the A6V and A6VM Series, like the A6VM140HA2T/63W-VZB380A model. You can get special packaging if you buy 10 or more. Our team helps you pick the right motor and gives you advice.

Tip: When you buy a hydraulic motor from us, you get one that fits your job. You can ask for special shapes, sizes, or packaging. We test every motor to make sure it is ready for you.

Hydraulic motors are important in many jobs. You see them in factories, farms, building sites, and ships. Each place uses these motors in its own way. They help people work faster and easier.

Factories use hydraulic motors in many machines. Motors run conveyor belts and presses. They also help with injection molding machines. Vane motors are good for fast jobs. They move parts quickly on conveyors. Gear motors give medium or high torque. This makes them good for heavy machines. Piston motors give strong power for hard tasks. They help lift or press things.

Some common factory uses are:

Moving conveyor belts

Running presses and cutters

Moving parts on assembly lines

We have motors for every job. Our team helps you pick the best motor for your factory.

Hydraulic motors help move and lift heavy things on building sites. Gear motors are used a lot in construction machines. They give strong torque and last a long time. You find these motors in excavators, cranes, and loaders.

Some uses in construction are:

Moving wheels and tracks

Lifting arms and buckets

Powering winches and drills

Our motors can handle hard work. They keep your machines working well.

On farms, hydraulic motors help plant and harvest crops. Piston motors are great for farm machines. They give high torque at slow speeds. You see these motors in tractors, harvesters, and grain augers.

Some key farm uses are:

Moving wheels and tracks

Running grain augers

Powering rotary tools

Hydraulic systems help you work better and faster. Our motors are made to last in tough farm places.

Hydraulic motors are used on ships and moving machines. These motors must stand up to saltwater and bad weather. Gear motors are easy to fix. Vane motors are light and help with steering. Safety parts, like pressure relief valves, keep things safe.

Some uses on ships and mobile machines are:

Steering and balancing boats

Powering winches and lifts

Running pumps and other tools

We make our motors with strong materials that do not rust. You get motors that work well, even in hard places.

Note: At Xiamen Senhengyuan Machinery Equipment Co., Ltd., we make special hydraulic motor solutions for every job. Our team gives expert help and service to fit your needs.

You have learned that a hydraulic motor uses fluid power to spin. These motors help machines move with strong and steady force. Every motor has important parts like the housing, shaft, and inside mechanism. You can pick gear, vane, or piston types for different jobs. When you choose a China hydraulic motor, make sure to check these things:

How much torque and speed you need

The highest pressure the motor can handle

How well the motor works

How often you will use the motor

The size and weight of the motor

Picking the right size helps your system stay safe and work well. At Xiamen Senhengyuan Machinery Equipment Co., Ltd., we give you great motors and expert help. Reach out to us for a custom hydraulic motor that fits what you need.

You use a hydraulic motor to turn fluid power into spinning motion. This helps machines lift, move, or rotate heavy parts. You find these motors in construction, farming, and factory equipment.

You should check the torque, speed, and pressure your machine needs. Look at the size and type of motor. If you need help, contact us. We are a trusted hydraulic motor manufacturer in China.

You should use clean fluid and check for leaks often. Replace filters when needed. Watch for strange noises or shaking. Regular care helps your high-quality motor last longer.

Yes! We offer custom solutions for your needs. Tell us your requirements. We will help you find the best China hydraulic motor for your job.

You get high-quality motors, strict testing, and expert support. We have over 10 years of experience as a hydraulic motor manufacturer. Our team helps you every step of the way.