Views: 0 Author: Site Editor Publish Time: 2025-09-30 Origin: Site

Hydraulic motors are integral components in various industrial and mobile applications, offering a unique combination of power, efficiency, and versatility. The three main types of hydraulic motors—gear motors, vane motors, and piston motors—each have distinct characteristics and applications. Understanding these differences is crucial for selecting the right motor for specific tasks. For more detailed information about hydraulic motors, you can explore the offerings from hydraulic motor manufacturers.

Gear motors are among the simplest types of hydraulic motors, known for their durability and efficiency. They operate by transferring fluid through a series of gears, which convert hydraulic energy into mechanical energy. These motors are typically used in applications where high speed and low torque are required. The straightforward design of gear motors makes them cost-effective and easy to maintain, which is why they are widely used in industrial settings.

In terms of performance, gear motors are best suited for applications that do not require precise control of speed and torque. They are commonly found in agricultural machinery, construction equipment, and material handling systems. Despite their simplicity, gear motors can be customized to fit specific operational needs, making them a versatile choice for many industries.

Vane motors, on the other hand, are known for their smooth operation and efficiency in converting hydraulic energy into mechanical energy. They consist of a rotor with sliding vanes that move in and out as the rotor turns, creating chambers that expand and contract to move fluid. This design allows vane motors to deliver consistent torque and speed, making them ideal for applications requiring precise control.

These motors are often used in industrial applications such as conveyor systems, machine tools, and injection molding machines. Their ability to provide smooth and consistent power makes them a preferred choice in environments where noise and vibration must be minimized. Additionally, vane motors are relatively compact, which allows for easy integration into existing systems.

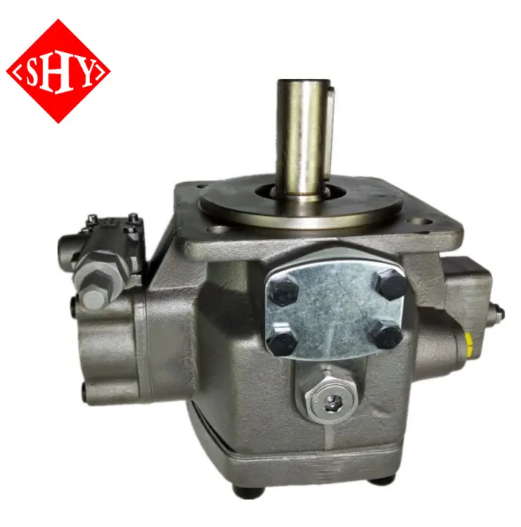

Piston motors are the most complex and versatile type of hydraulic motor, offering high efficiency and performance. They use pistons driven by hydraulic fluid to create rotational motion, allowing for high torque and speed capabilities. Piston motors are available in two main configurations: axial and radial. Axial piston motors are known for their compact design and high power density, while radial piston motors offer excellent torque at low speeds.

These motors are commonly used in heavy-duty applications such as construction equipment, marine propulsion systems, and industrial machinery. Their ability to handle high pressures and deliver precise control makes them suitable for demanding environments. Piston motors are also highly adaptable, with various configurations available to meet specific operational requirements.

When comparing the three main types of hydraulic motors, several factors must be considered, including efficiency, cost, and application suitability. Gear motors are the most economical option, offering simplicity and reliability for basic applications. Vane motors provide a balance of efficiency and control, making them suitable for applications requiring smooth operation. Piston motors, while more expensive, offer the highest performance and adaptability for complex and demanding tasks.

The choice of motor depends largely on the specific requirements of the application, including the desired speed, torque, and control. For applications requiring high torque and precision, piston motors are often the best choice. In contrast, for applications where cost is a primary concern, gear motors may be more appropriate. Vane motors are ideal for applications that require a balance of performance and cost-effectiveness.

Hydraulic motors are used across a wide range of industries, from agriculture and construction to manufacturing and marine. Each type of motor has specific advantages that make it suitable for particular applications. Gear motors are commonly used in agricultural equipment and material handling systems, where simplicity and reliability are paramount. Vane motors are often found in industrial machinery and conveyor systems, where smooth operation is essential.

Piston motors are used in heavy-duty applications such as construction equipment and marine propulsion systems, where high performance and precision are required. The versatility of hydraulic motors allows them to be customized to meet the specific needs of different industries, ensuring optimal performance and efficiency. For those looking to explore more about hydraulic motors and their applications, the hydraulic motor high torque options are worth considering.

In conclusion, understanding the differences between gear, vane, and piston motors is essential for selecting the right hydraulic motor for your application. Each type of motor offers unique advantages and is suited to specific tasks, from simple, cost-effective solutions to high-performance, precision applications. By carefully considering the requirements of your application, you can choose the most suitable motor to enhance efficiency and performance. For more information on hydraulic motors and to explore potential solutions, consider reaching out to a hydraulic motor manufacturer.

1. What are the main differences between gear, vane, and piston motors?

Gear motors are simple and cost-effective, vane motors offer smooth operation, and piston motors provide high performance and precision.

2. Which type of hydraulic motor is best for high torque applications?

Piston motors are best suited for high torque applications due to their ability to handle high pressures and deliver precise control.

3. Are vane motors suitable for industrial applications?

Yes, vane motors are ideal for industrial applications requiring smooth and consistent power, such as conveyor systems and machine tools.

4. How do gear motors compare in terms of cost and maintenance?

Gear motors are the most economical option, offering simplicity and ease of maintenance, making them suitable for basic applications.

5. Can hydraulic motors be customized for specific applications?

Yes, hydraulic motors can be customized to meet specific operational needs, ensuring optimal performance and efficiency.

6. What industries commonly use hydraulic motors?

Hydraulic motors are used in agriculture, construction, manufacturing, and marine industries, among others.