Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

Hydraulic pumps are essential components in various industries, including construction, manufacturing, oil and gas, agriculture, and heavy machinery. The performance and reliability of these systems depend heavily on the quality of the pumps they use. Consequently, finding a trustworthy hydraulic pump supplier is critical for any business seeking to ensure operational efficiency, minimize downtime, and reduce maintenance costs.

Selecting the right supplier, however, is not always straightforward. The hydraulic pump market is competitive and diverse, with suppliers varying in product quality, technological expertise, delivery capabilities, and customer service. A reliable supplier can provide high-quality products, technical support, timely delivery, and long-term partnership opportunities. This article provides a comprehensive guide on how to find a trustworthy hydraulic pump supplier, outlining key factors to consider, strategies for evaluation, and tips for building a successful business relationship.

Before searching for a hydraulic pump supplier, it is important to clearly define your business needs. Different industries and applications require different types of pumps with specific performance characteristics.

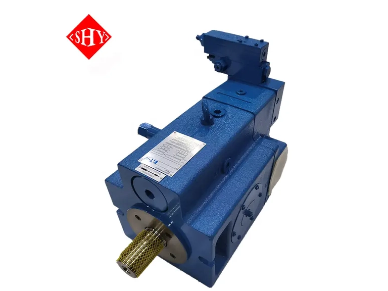

Identify the type of hydraulic pumps required for your operations, such as gear pumps, piston pumps, vane pumps, or custom designs. Consider factors like flow rate, pressure rating, operating temperature, fluid type, and environmental conditions. Knowing these specifications will help you filter potential suppliers who can meet your technical requirements.

Assess the expected volume of pumps required and the frequency of orders. Some suppliers excel in small-batch or custom orders, while others are better suited for high-volume industrial supply. Understanding your demand ensures that the supplier can scale production and meet delivery deadlines.

Ensure that the pumps you require comply with industry standards, such as ISO, API, or CE certifications. Suppliers adhering to recognized standards are more likely to provide high-quality products suitable for demanding industrial applications.

Once your requirements are clear, the next step is to research potential suppliers. This involves gathering information about their reputation, product range, experience, and customer service.

Start with online research to identify suppliers in your region or internationally. Company websites, industry directories, and trade platforms provide valuable information about product offerings, certifications, and technical expertise. Look for suppliers with detailed product specifications, case studies, and client testimonials, which indicate experience and reliability.

Seek recommendations from industry peers, trade associations, or professional networks. Businesses with similar operations can provide insights into their experiences with specific suppliers, highlighting reliability, responsiveness, and overall quality.

Attending industry trade shows and exhibitions can help you meet potential suppliers in person. These events provide opportunities to evaluate products, discuss technical specifications, and assess the supplier’s commitment to innovation and quality firsthand.

Not all suppliers offer the same level of quality and reliability. Evaluating credibility is crucial to avoid future operational problems.

Check whether the supplier holds relevant certifications, such as ISO 9001 for quality management or CE marking for compliance with European standards. Certifications indicate adherence to industry best practices and consistent manufacturing quality.

A supplier with a long-standing presence in the hydraulic pump industry is more likely to have proven expertise and reliable processes. Evaluate their track record through case studies, client references, and years of experience in manufacturing and supplying pumps.

Assess the financial stability of the supplier to ensure they can meet long-term commitments. A financially sound supplier is less likely to face production delays, material shortages, or other operational disruptions that could affect your business.

High-quality products and technological capabilities are essential features of a trustworthy hydraulic pump supplier.

Examine the materials used in pump construction. High-quality pumps are made from durable, corrosion-resistant metals and precision-engineered components. Material quality affects pump longevity, efficiency, and maintenance requirements.

Suppliers that invest in research and development demonstrate a commitment to innovation and continuous improvement. Advanced designs, energy-efficient models, and customizable solutions indicate that the supplier can meet evolving industry demands.

Reliable suppliers conduct rigorous testing and quality assurance at each stage of production. Look for evidence of performance testing, durability assessments, and compliance with industry standards. Quality assurance ensures that pumps operate efficiently and safely under industrial conditions.

A trustworthy supplier must be capable of delivering products on time and supporting your supply chain needs.

Discuss lead times and production capacity with potential suppliers. Ensure they can deliver the required volume within your operational schedule, especially for critical applications where downtime can be costly.

Evaluate the supplier’s logistics and shipping capabilities. Reliable suppliers offer secure packaging, efficient transportation, and tracking systems to ensure that products arrive safely and on schedule.

Strong after-sales support is a hallmark of a trustworthy supplier. This includes installation guidance, technical support, spare parts availability, and maintenance services. A supplier who provides ongoing assistance contributes to the long-term reliability of your hydraulic systems.

Finding a supplier is only the beginning of a successful business partnership. Establishing a strong, long-term relationship with your hydraulic pump supplier is crucial for ensuring consistency, reliability, and mutual benefits over time. A dependable supplier becomes more than just a vendor—they become a strategic partner who can contribute to your operational efficiency, innovation, and overall business growth. Developing such a relationship requires deliberate effort, trust, and ongoing engagement.

Clear and transparent communication is the foundation of any successful supplier relationship. It involves more than just discussing prices or delivery dates; it includes openly sharing technical specifications, production requirements, and future plans. By maintaining transparent communication, both parties can anticipate potential challenges, adjust production schedules, and implement necessary changes proactively. Regular meetings, progress updates, and timely responses to queries foster trust and prevent misunderstandings that could lead to delays, defects, or operational inefficiencies.

Periodic performance reviews are essential for monitoring the supplier’s adherence to agreed standards. These reviews allow your business to evaluate whether the supplier consistently meets quality, delivery, and service expectations. Feedback collected during these assessments can be used constructively to address minor issues before they escalate into larger problems. Over time, performance reviews create a feedback loop that strengthens accountability, encourages continuous improvement, and ensures that both your business and the supplier maintain high operational standards.

A strategic partnership approach transforms the supplier-client relationship from a transactional interaction into a collaborative effort. Treating your supplier as a partner involves jointly exploring ways to improve product design, enhance technical performance, and optimize supply chain processes. Collaborative problem-solving can lead to innovations that benefit both parties, such as energy-efficient pump designs, faster production cycles, or cost-saving manufacturing techniques. Additionally, a strong partnership often leads to preferential treatment in terms of priority production, early access to new technologies, and shared risk management, providing long-term stability and a competitive edge for your business.

While evaluating suppliers, be aware of potential red flags that may indicate unreliability:

Lack of industry certifications or standards compliance

Limited product information or technical documentation

Negative client reviews or inconsistent references

Poor communication or unresponsiveness

Unrealistically low pricing without clear justification

Avoiding suppliers with these characteristics helps prevent operational risks and ensures long-term business success.

Finding a trustworthy hydraulic pump supplier is essential for businesses that rely on hydraulic systems for efficient and reliable operations. By understanding your technical requirements, researching potential suppliers, evaluating credibility, assessing product quality, and ensuring robust supply chain support, businesses can identify suppliers who meet their operational and strategic needs.

Building long-term relationships with reliable suppliers, maintaining clear communication, and leveraging their expertise contributes to consistent pump performance, reduced downtime, and cost-effective operations.

Among the leading hydraulic pump suppliers that exemplify quality, reliability, and industry expertise is Xiamen Senhengyuan Machinery Equipment Co., Ltd. Their commitment to innovation, rigorous quality assurance, and comprehensive after-sales support makes them a trusted partner for businesses seeking durable and high-performance hydraulic pumps across various industrial applications.